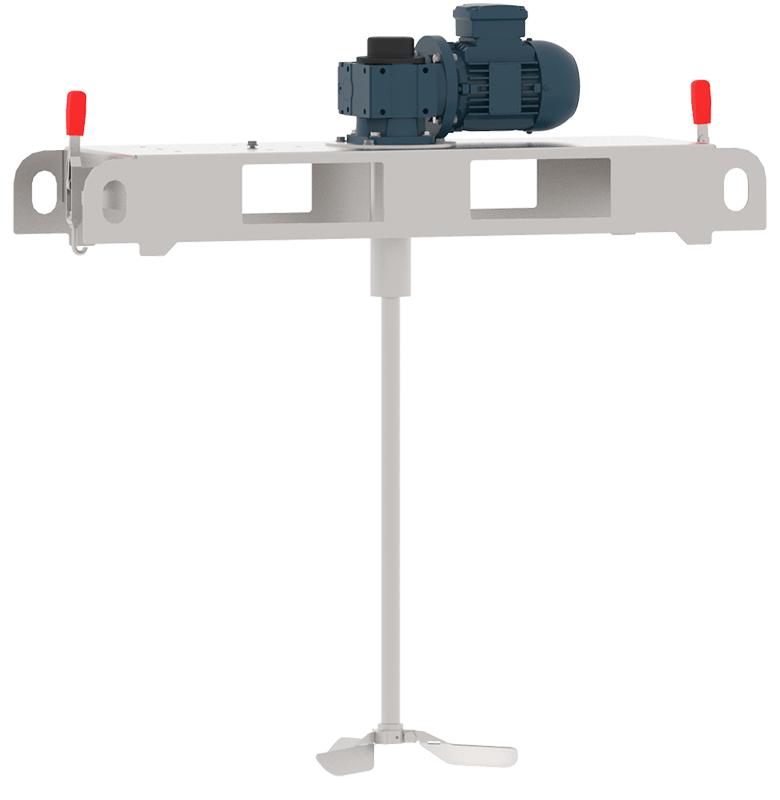

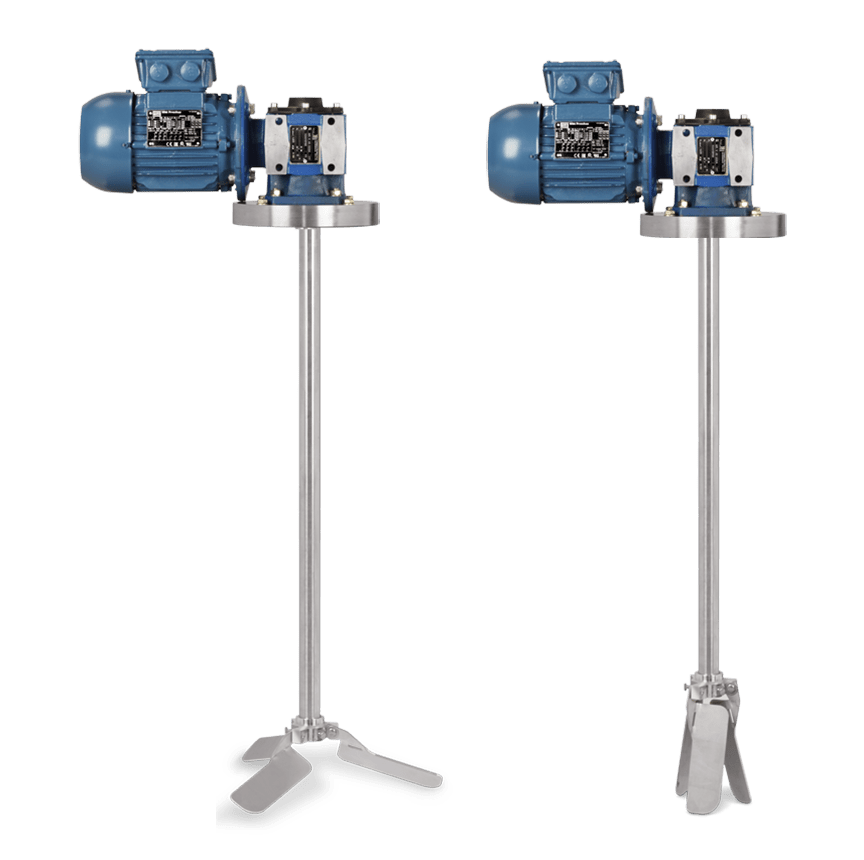

INDUSTRIAL MIXERS WITH COLLAPSIBLE BLADES

AF FOLDING MIXERS

TOP-ENTRY GEARED MIXERS WITH FLANGE FOR OPEN TANKS AT ATMOSPHERIC PRESSURE. WITH CANTILEVER SHAFT COUPLED TO THE GEARMOTOR WITH A JOINT. IMPELLERS WITH COLLAPSIBLE BLADE DESIGN. LOW ROTATIONAL SPEED.

- Corrosion-resistant industrial mixers.

- Slow-speed agitation (with worm gear reducer).

- 4/6-pole electric motors.

- Mixer and propeller material: AISI 304.

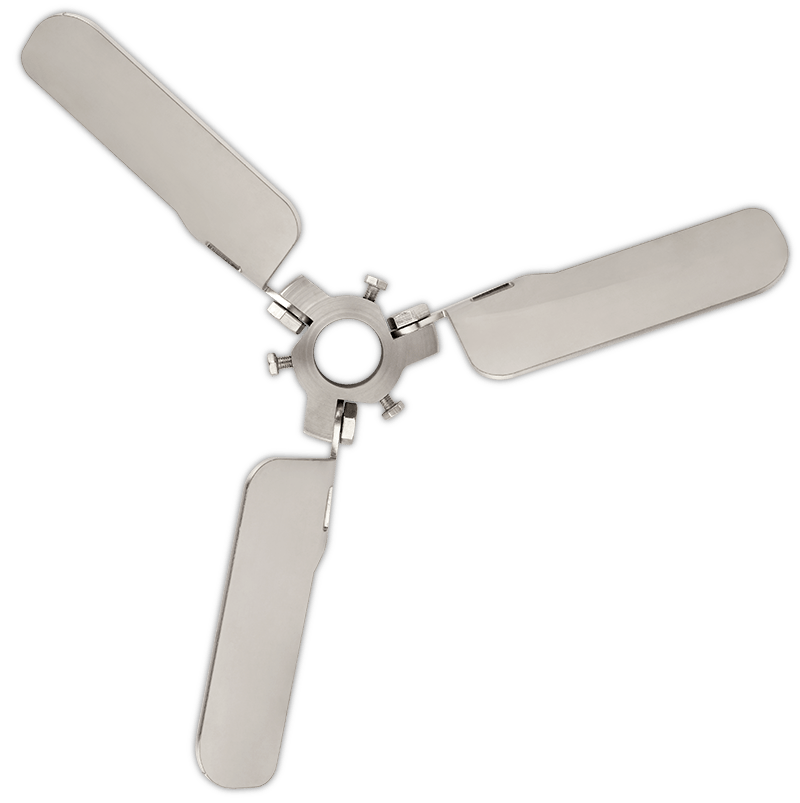

- High-efficiency 3-blade folding impellers.

- Folding impeller closed: minimum opening Ø 100 mm.

- Maximum blades diameter (propeller operating): 400 mm.

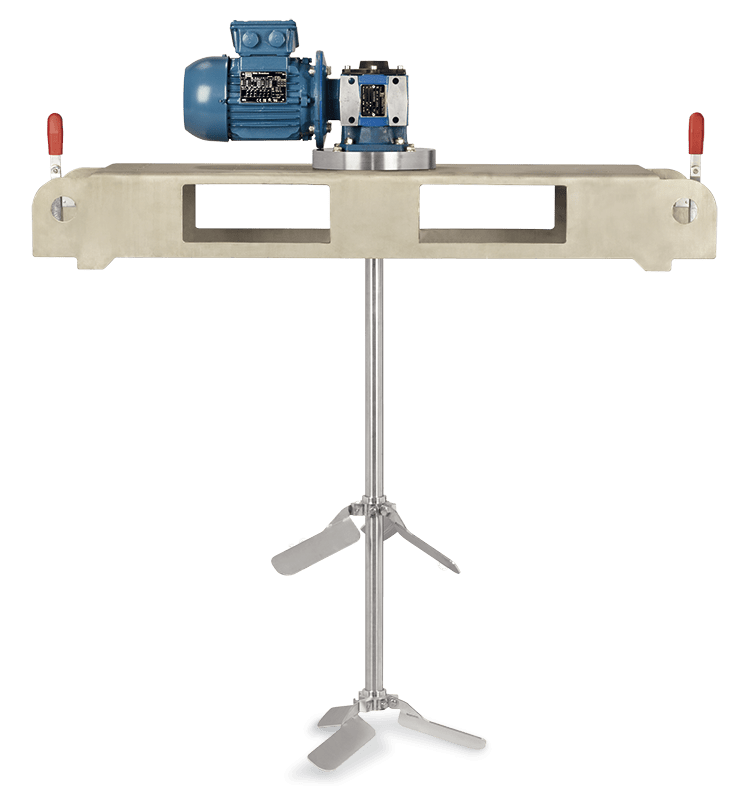

- Optionally fitted with a second folding propeller.

- Custom-made lengths between 500 and 2000 mm.