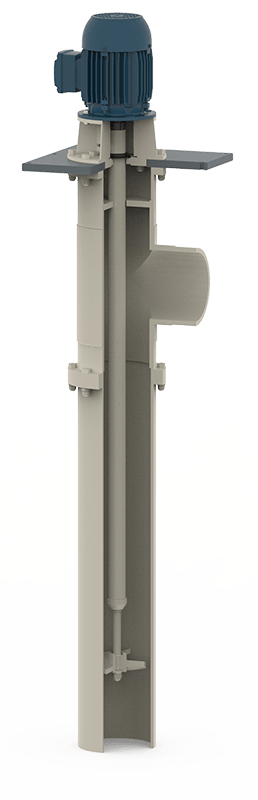

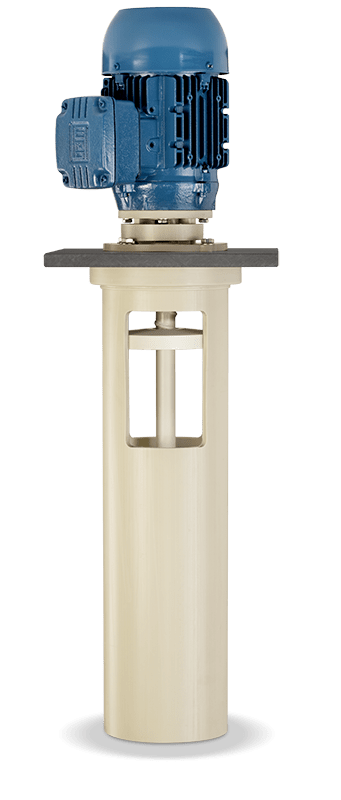

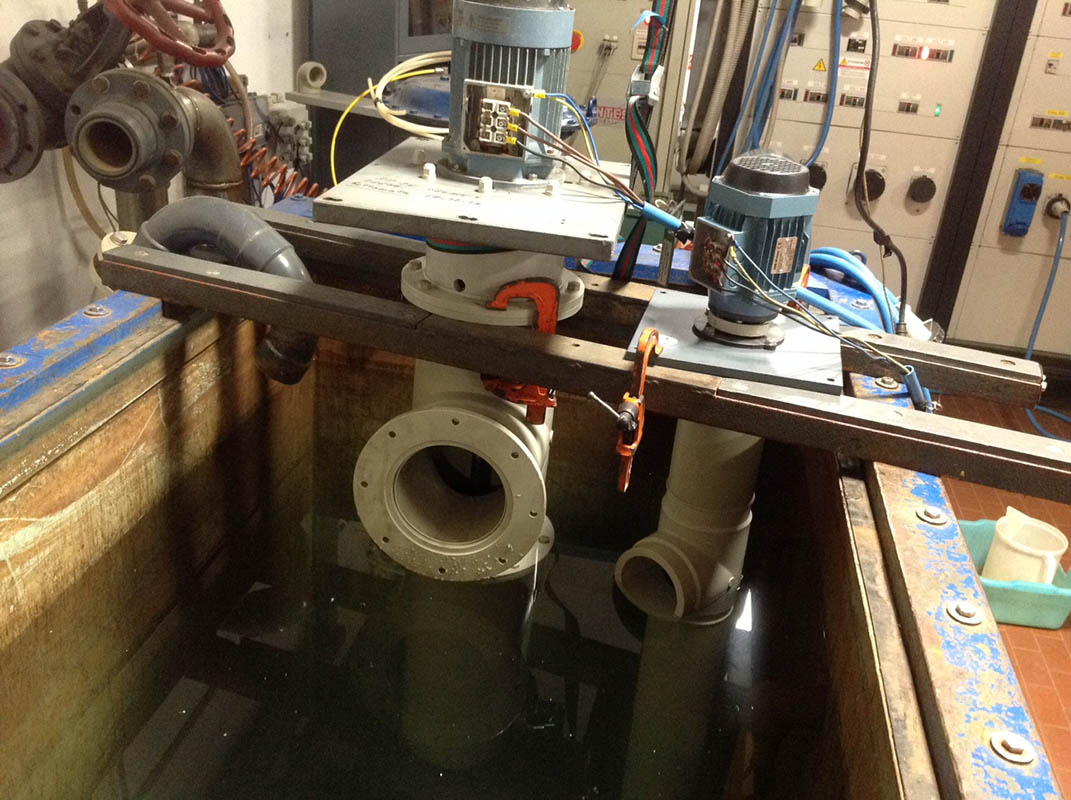

INDUSTRIAL MIXERS WITH INTUBATED IMPELLER

AP PUMPING MIXERS

TOP MOUNT MIXERS WITH FLANGE FOR OPEN TANKS. EQUIPPED WITH SUCTION PIPE. SUITABLE FOR LONG AND NARROW TANKS (E.G., ELECTROPLATING BATHS AND OTHER METAL TREATMENTS) AND FURTHER MIXING OPERATIONS WHERE A POWERFUL AGITATION IS REQUIRED.

- Corrosion-resistant industrial mixers.

- High-speed mixers (with no gear reducer).

- 4-6-8-pole electric motors.

- High flow rates and low installed power.

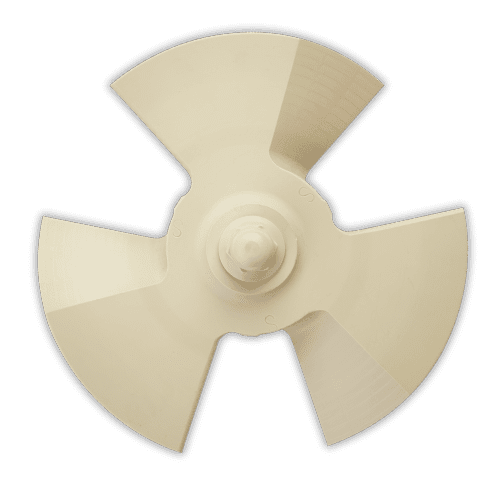

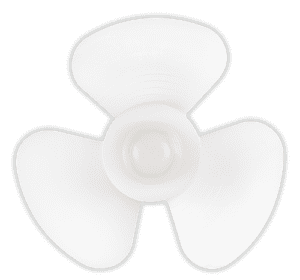

- Reversible marine propeller.

- Powerful movement of the liquid.

- Mixer materials: PP, PVC, PVDF.

- Impeller materials: PP, PVC, PVDF.

- Cantilevered shaft inserted in a suction pipe.

- Custom-made lengths from 750 to 2000 mm.