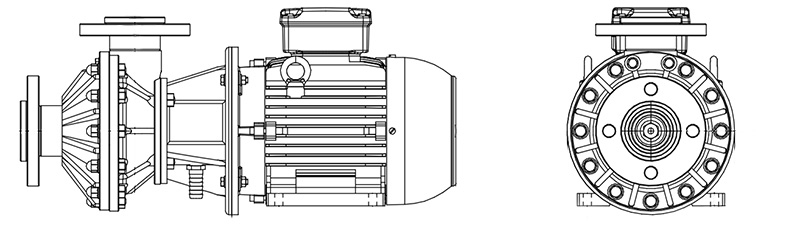

CORROSION-RESISTANT PLASTIC PUMPS

CHEMICAL PUMP CONFIGURATION

HOW TO CORRECTLY SIZE A CHEMICAL PUMP FOR AGGRESSIVE LIQUIDS

Thanks to a wide range of sizes, materials and accessories, Savino Barbera plastic pumps are perfectly compatible with a variety of aggressive fluids and countless industrial systems. When we select a particular model of chemical pump, we always do so on the basis of precise functional reasons and without unnecessary over-dimensioning: this is the only way to avoid poor performance or undesirable failures. Our experience represents a decisive added value, especially in view of the changing and uncertain conditions that often occur with corrosive liquids. When choosing a pump, never forget one basic rule: overdoing things costs money!

CRUCIAL INFORMATION

The sizing of corrosion-resistant pumps for chemical applications involves the careful assessment of numerous factors. This analysis is necessary not only to determine the correct size but also to identify the thermoplastic material that is chemically compatible with the aggressive nature of the liquids to be pumped. So, in order to configure the chemical pump best suited to the specific case, it is essential to have a precise knowledge of the following fundamental parameters:

- flow rate and head values (the exact working point)

- pump length or tank depth (vertical pumps)

- position of the tank in relation to the pump (horizontal pumps)

- length of the suction pipe (horizontal pumps)

- chemical-physical nature of the aggressive liquid to be pumped

- temperature and concentration of the aggressive liquid to be pumped

- possible presence of solids suspended in the corrosive liquid pumped

- type of connections required (hose adaptor, threaded connection, flange)

- special motor requirements (phases, Volt, Hertz, protections…)

- known features of the system (leakages, accessories, etc.)

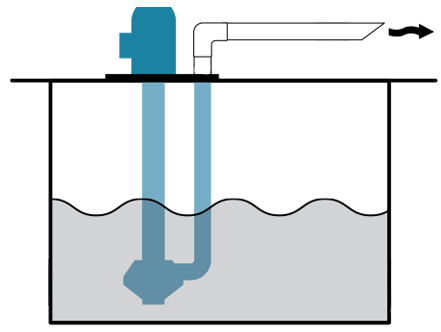

VERTICAL PUMP SELECTION GUIDELINES

To correctly size a vertical axis chemical pump, in addition to information relating to the performance required of the system and the chemical nature of the aggressive liquid to be pumped, it is also necessary to know the length of the pump (or the depth of the installation tank), paying attention to the levels of the liquid (minimum and maximum) and the minimum distance from the bottom of the tank.

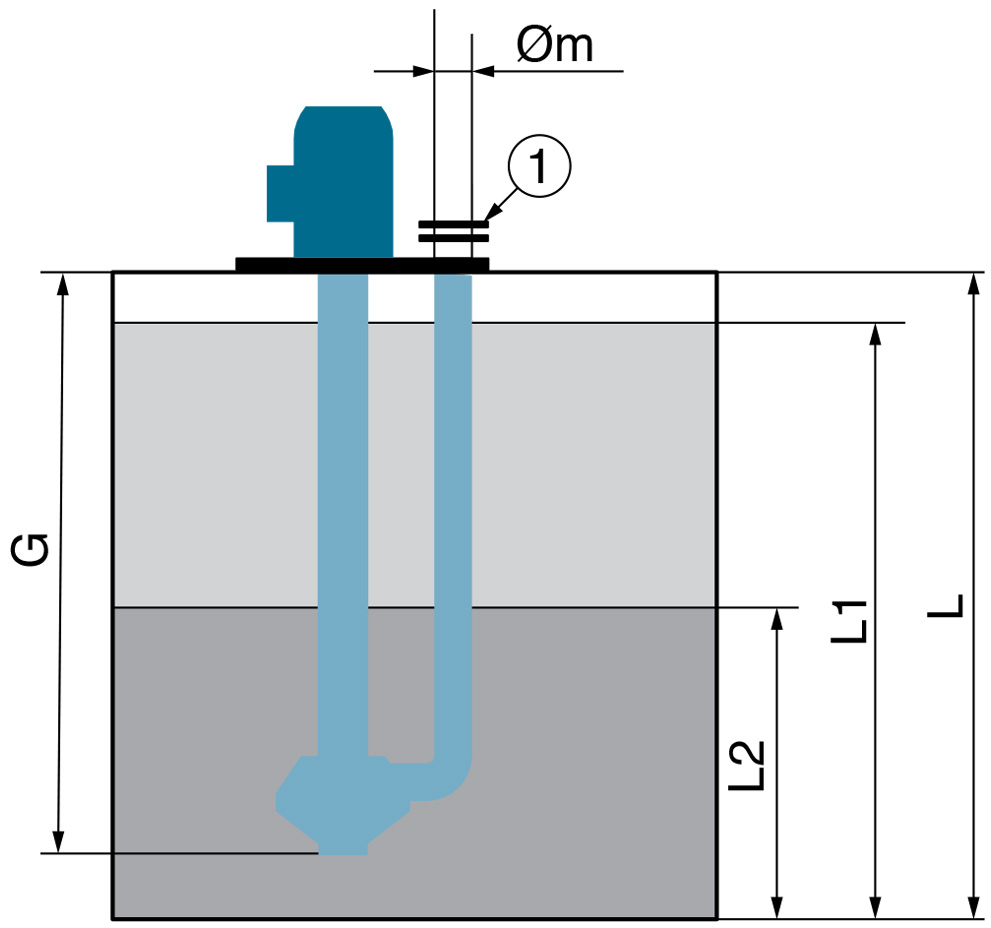

VERTICAL PUMP WITH IMMERSED COLUMN

- G: pump length

- L: tank depth

- L1: maximum level

- L2: minimum level

- 1: delivery pipe connection

- Ø: delivery pipe diameter

POLYPROPYLENE VERTICAL-AXIS PUMP

AS50 vertical pump made of polypropylene, a material chosen for its chemical compatibility with the corrosive liquids pumped: washing water with sodium hydroxide, hydrofluoric acid and phosphoric acid. The pump is 2960 mm long (and has an external fibreglass reinforcement). Maximum flow rate: 40 m3/h. Maximum head: 25 m w.c.

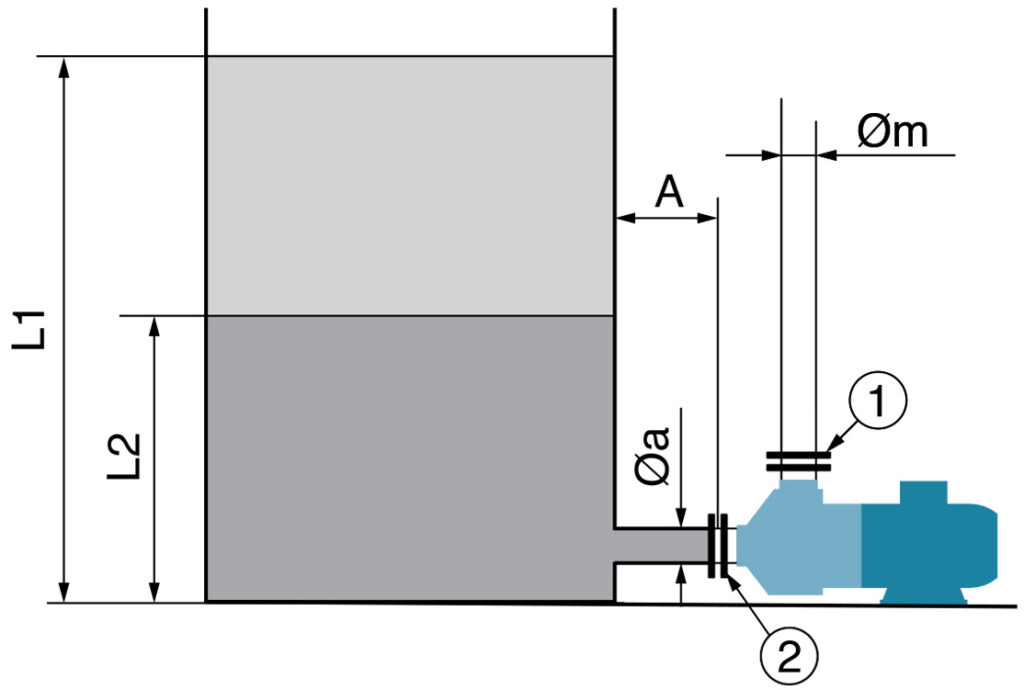

HORIZONTAL PUMP SELECTION GUIDELINES

In order to correctly select a horizontal chemical pump, in addition to the usual information regarding its performance and the liquid pumped, it is necessary to distinguish between under-flooded installation (pump UNDER the surface of the liquid, which is normally the most common and safe solution) or self-priming installation (pump ABOVE the surface of the liquid, which is a much more delicate arrangement).

UNDER FLOODED INSTALLATION

- A: suction pipe length

- L1: maximum level

- L2: minimum level

- 1: delivery pipe connection

- 2: suction pipe connection

- Øa: suction pipe diameter

- Øm: delivery pipe diameter

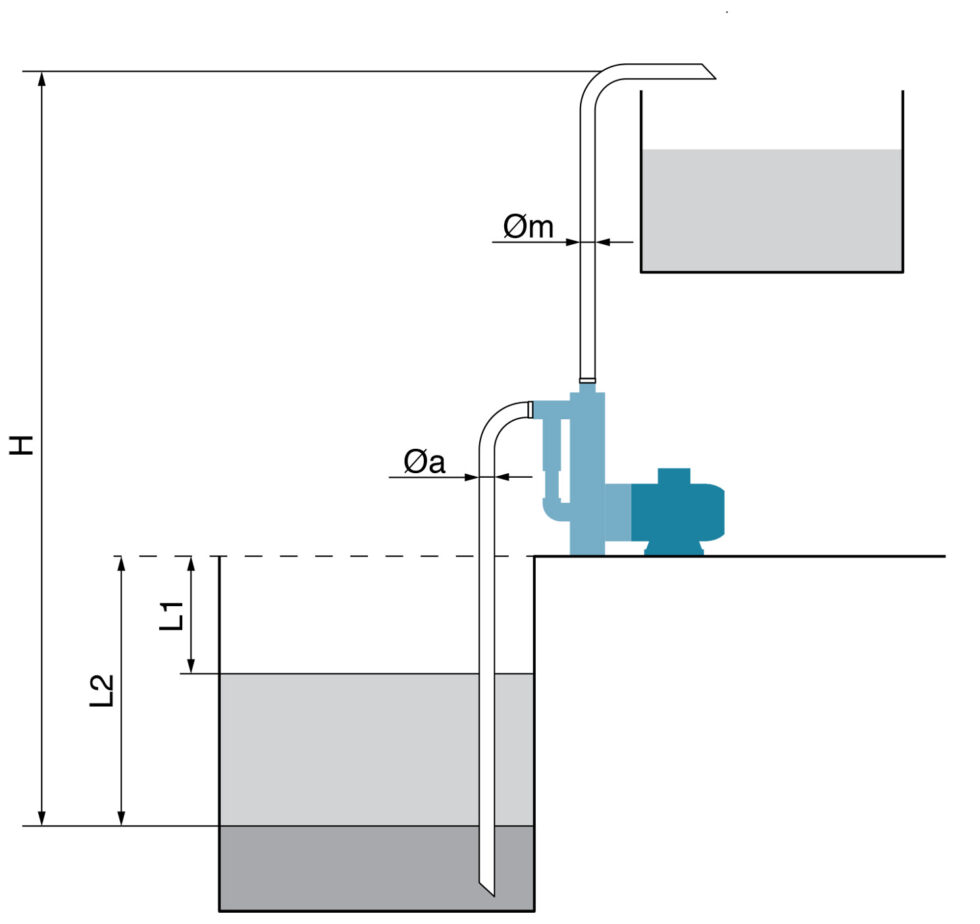

SELF-PRIMING INSTALLATION

- H: suction pipe length

- L1: maximum level

- L2: minimum level

- Øa: suction pipe diameter

- Øm: delivery pipe diameter

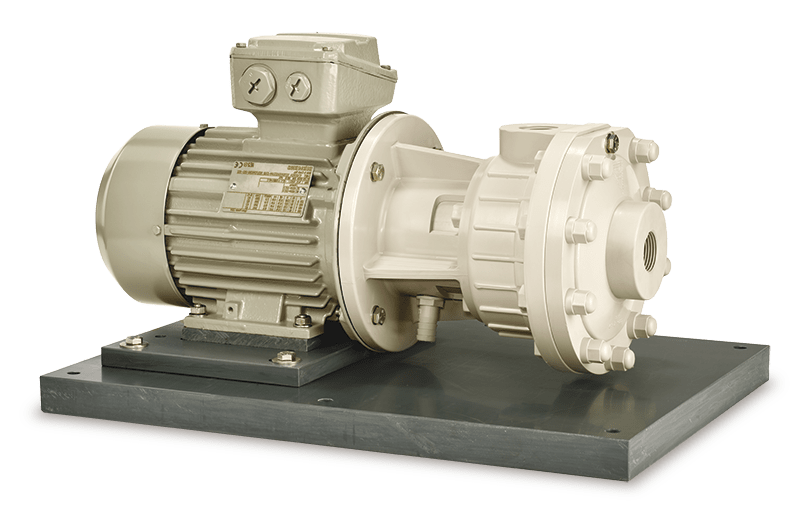

POLYPROPYLENE HORIZONTAL-AXIS PUMP

OMA30 horizontal thermoplastic pump anchored to a sturdy PVC baseplate and equipped with a tropicalised motor suitable for very humid environments. Female threaded connections. Application: pumping of regeneration water in a softening system. Operating temperature: 45°C. Maximum flow rate: 12 m3/h. Maximum head: 10 m w.c.

download area

CHEMICALLY-RESISTANT PUMPS AND MIXERS

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS