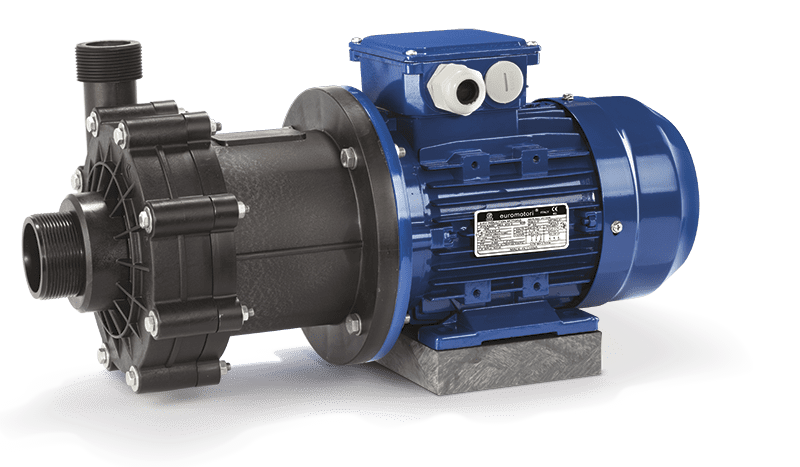

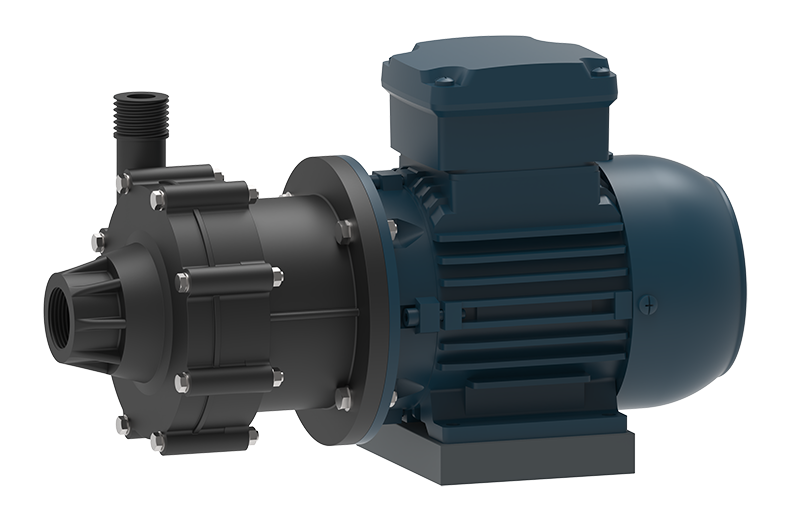

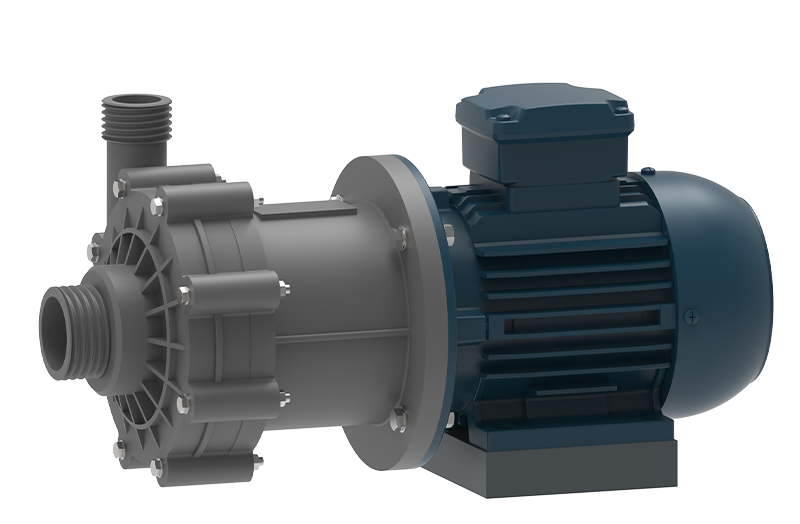

MAGNETICALLY DRIVEN CHEMICAL PUMPS

PLASTIC MAGNETIC PUMPS

MAG DRIVE CHEMICAL PUMPS CONSTRUCTED FROM POLYPROPYLENE OR PVDF. HERMETIC DESIGN WITH NO MECHANICAL SEAL. LEAK-PROOF MAGNETIC PUMPS IDEAL FOR TOXIC AND HAZARDOUS LIQUIDS. PRINCIPLE INDUSTRIES SERVED INCLUDE CHEMICAL, PETROCHEMICAL, PHARMACEUTICAL AND ELECTROPLATING APPLICATIONS.

- Acid-resistant seal-free chemical pumps.

- Maximum flow rate: 135 m³/h.

- Maximum head: 48 m w.c.

- Plastic construction materials: PP, PVDF.

- Threaded pumps (standard version) or with flange (by request).

- Opposing magnets encapsulated in corrosion-resistant plastic.

- Neodymium iron and boron permanent magnets (NdFeB).

- Also for explosive environments (specific models by request).

- Only for clean liquids with no solids (especially if metallic).

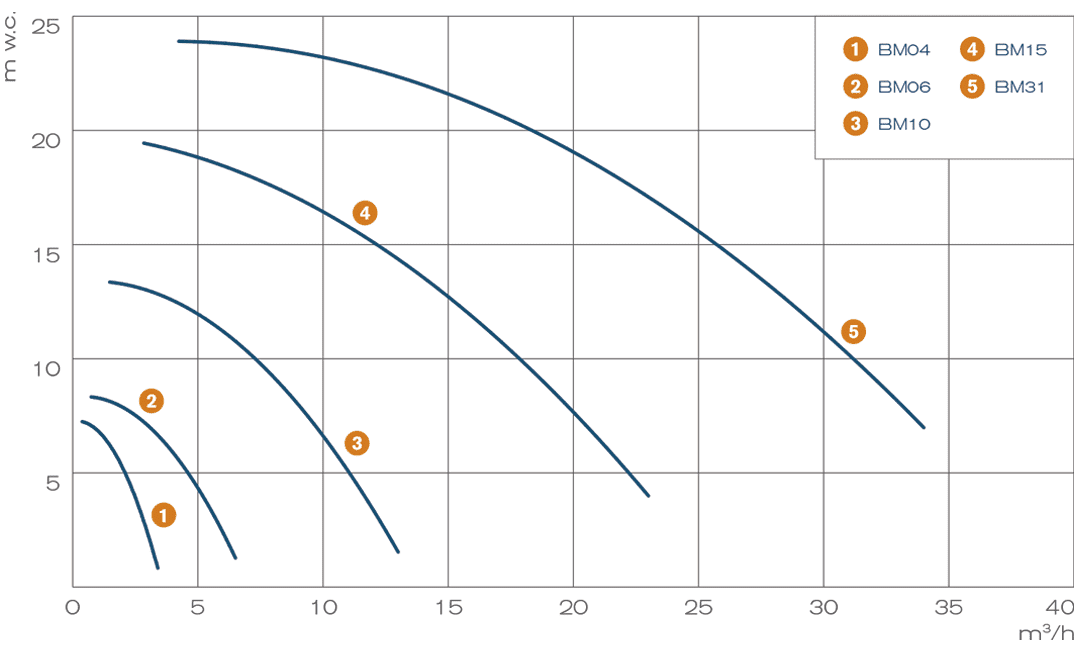

BM SERIES: BM04 → BM31 models

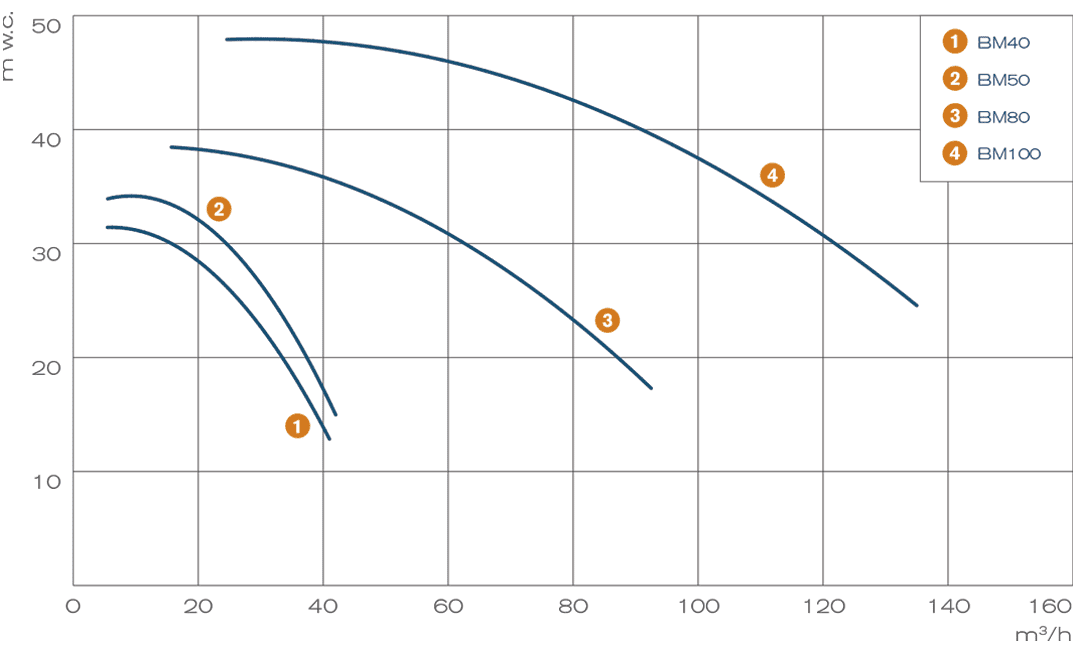

BM SERIES: BM40 → BM100 MODELS

Standard curves: 50 Hz (60 Hz curves available on request). Maximum rated pressure: PN6 @ 20°C. The curves refer to tests with cold, clean water and a density of 1000 kg/m3 (ISO9906). Hydraulic performance may change in relation to changes in the characteristics of the liquid to be pumped.

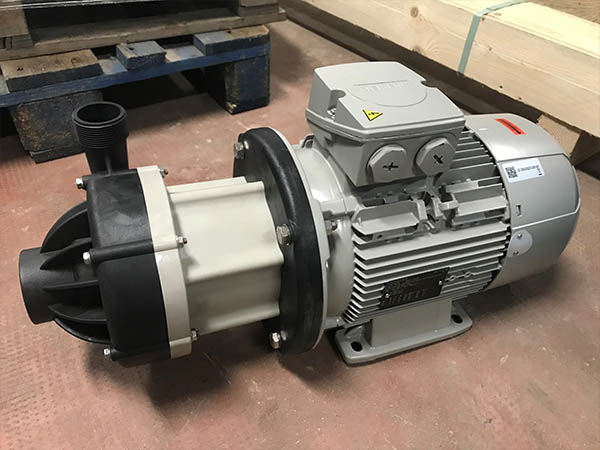

Special non-standard motors can also be mounted: in this case, we recommend that you contact our technical department.

MD SERIES: MD06 → MD70 MODELS

Special non-standard motors can also be mounted: in this case, we recommend that you contact our technical department.

download area

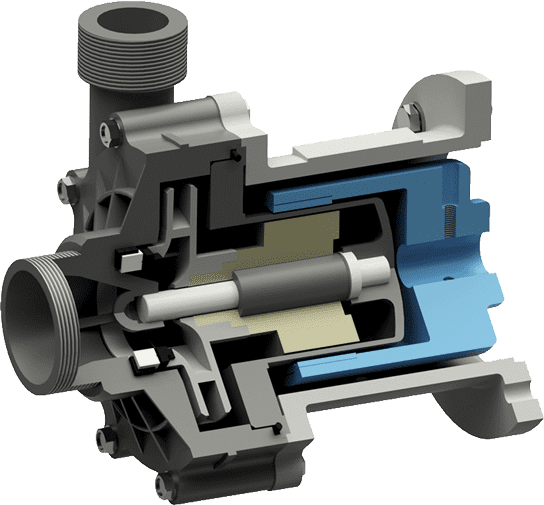

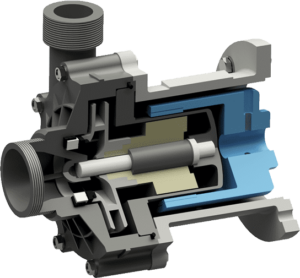

MAGNETIC DRIVE COUPLING

SEALLESS PUMPS

The absence of dynamic seals and magnetic coupling between pump and motor, at least virtually, prevent external leakage. Their maintenance, however, is usually more expensive than with pumps with mechanical seals.

CONTACT-FREE

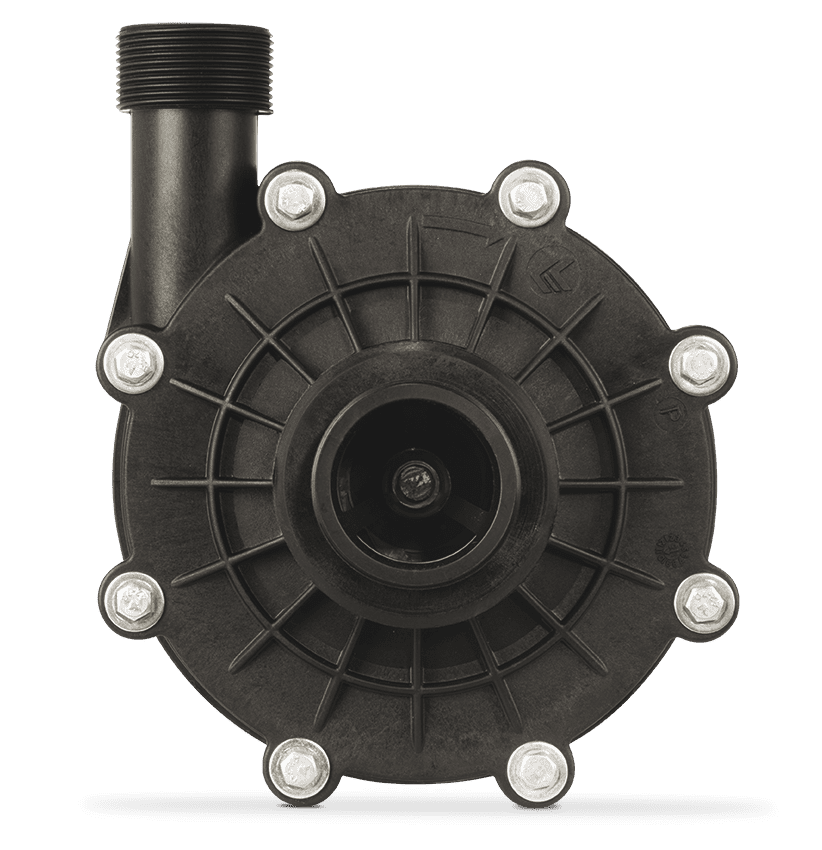

The external magnet, coupled to the motor shaft, conveys movement to the internal magnet which is attached to the impeller. As the motor shaft does not extend inside the pump body, the contact-free magnetic pump is incapsulated and protected from corrosion.

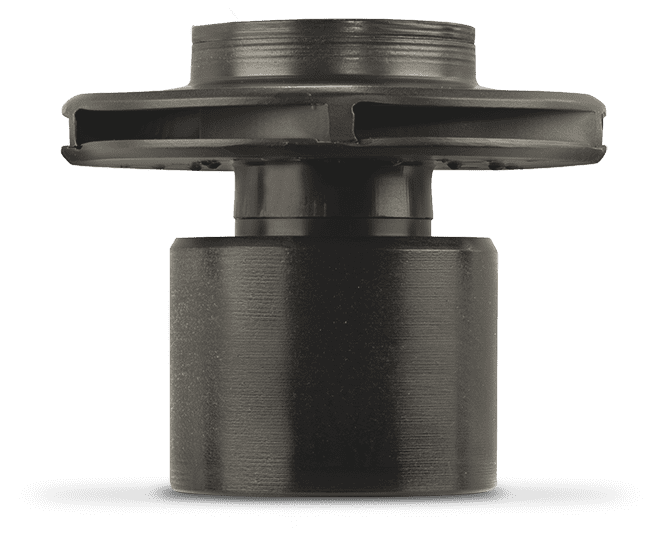

CLEAN LIQUIDS ALWAYS

The thin plastic coating of the magnets and the closed channels of the impellers do not withstand liquids with abrasive solids and suspended particles, especially when metallic. Over-saturated liquids could also pose a problem for magnetic pumps.

HIGH-CHEMICAL RESISTANCE

Savino Barbera magnetically driven pumps mount closed impellers, made of corrosion-resistant plastic. The anti-acid thermoplastic materials used foe are PP and PVDF.

SEALLESS PUMPS

The absence of dynamic seals and magnetic coupling between pump and motor, at least virtually, prevent external leakage. Their maintenance, however, is usually more expensive than with pumps with mechanical seals.

HIGH-CHEMICAL RESISTANCE

Savino Barbera magnetically driven pumps mount closed impellers, made of corrosion-resistant plastic. The anti-acid thermoplastic materials used foe are PP and PVDF.

CLEAN LIQUIDS ALWAYS

The thin plastic coating of the magnets and the closed channels of the impellers do not withstand liquids with abrasive solids and suspended particles, especially when metallic. Over-saturated liquids could also pose a problem for magnetic pumps.

CONTACT-FREE

The external magnet, coupled to the motor shaft, conveys movement to the internal magnet which is attached to the impeller. As the motor shaft does not extend inside the pump body, the contact-free magnetic pump is incapsulated and protected from corrosion.

SEALED PUMPS VS MAGNETIC PUMPS

Magnetic pumps are considered to be hermetically sealed pumps. Their presumed tightness must be scrupulously evaluated in relation to the characteristics of the liquid being pumped. The choice of mag-drive pumps can be influenced by incorrect installation habits rather than by real technical needs. Magnetically coupled pumps are often preferred to mechanically sealed pumps in the belief that the former are safer, but their use requires particular attention to specific working conditions.

CONSTRUCTION MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of anti-acid centrifugal pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

PVDF (POLYVINYLDENFLUORIDE)

Fluorinated thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

KEY CHEMICALS

- Sulphuric acid

- Hydrochloric acid

- Chromic acid

- Hydrofluoric acid

- Acetic acid

- Phosphoric acid

- Caustic soda

- Nitric acid

- Formic acid

- Sodium chloride

- Photographic liquids

- Urea and AdBlue

- Hydrogen peroxide

- Demineralised water

- Ferric chloride

- Bromides

- Aluminium polychloride

- Electroplating baths

- Hydrogen dioxide

- Potassium hydroxide

- Cyanides

- Ammonia

- Brine

- And your liquid, of course!

KEY CHEMICALS

- Sulphuric acid

- Hydrochloric acid

- Chromic acid

- Hydrofluoric acid

- Acetic acid

- Phosphoric acid

- Caustic soda

- Nitric acid

- Formic acid

- Sodium chloride

- Photographic liquids

- Urea and AdBlue

- Hydrogen peroxide

- Demineralised water

- Ferric chloride

- Bromides

- Aluminium polychloride

- Electroplating baths

- Hydrogen dioxide

- Potassium hydroxide

- Cyanides

- Ammonia

- Brine

- And your liquid, of course!

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST MAG-DRIVE PUMPS SUPPLIES

CHEMICAL MAG-DRIVE PUMPS

Chemical transfer magnetic drive pumps made from polypropylene for acidic and alkaline oxidizing solutions.

PLASTIC MAGNETIC DRIVE PUMPS

Leakproof sealless magnetic pumps manufactured from PVDF (casing) and FPM (o-ring) for corrosive applications.

PUMPS WITH HERMETIC DESIGN

Polypropylene horizontal magnetically driven pumps with hermetic design for circulating mildly corrosive acids.

PUMPS FOR AMMONIUM SULFATE

Corrosion-resistant chemical mag-drive pumps for ammonium sulfate with a density of 1270 kg/m3.

MAGNETIC PUMP FOR SULFURIC ACID

Chemical magnetic drive centrifugal pump for handling highly corrosive 96% sulfuric acid. Material: PVDF.

NO NEED FOR MECHANICAL SEAL

Magnetic pumps feature a sealless mag-drive design eliminating the need for mechanical seals and possible leaks.

SODIUM & MAGNESIUM CHLORIDE

Pump with magnetic coupling for a safe transfer of a corrosive sodium chloride and magnesium chloride solution.

SUITABLE FOR OXALIC ACID

Non corrosive centrifugal sealless magnetic drive pumps for chemical applications based on 2% oxalic acid.

USED FOR PERACETIC ACID

Magnetically driven pumps for peracetic acid equipped with two different motors: single-phase and three-phase.

PVDF FOR HYDROCHLORIC ACID

Non metallic magnetic pump without mechanical seal for pumping 33% concentration hydrochloric acid.

WITH 50% SODIUM HYDROXIDE

Chemical resistant mag-drive pumps in thermoplastic material (polypropylene) for 50% caustic soda (NaOH).

FOR CLEAN LIQUIDS ONLY

Magnetic pumps are senstive to harsh conditions: they can hanlde clean liquid without suspended solids.

LEAK PROOF MAGNETIC DESIGN

Acid resistant magnetic pump driven by opposite magnets. Suitable plastic for water: polypropylene (PP).

FURTHER CORROSION RESISTANT PUMPS