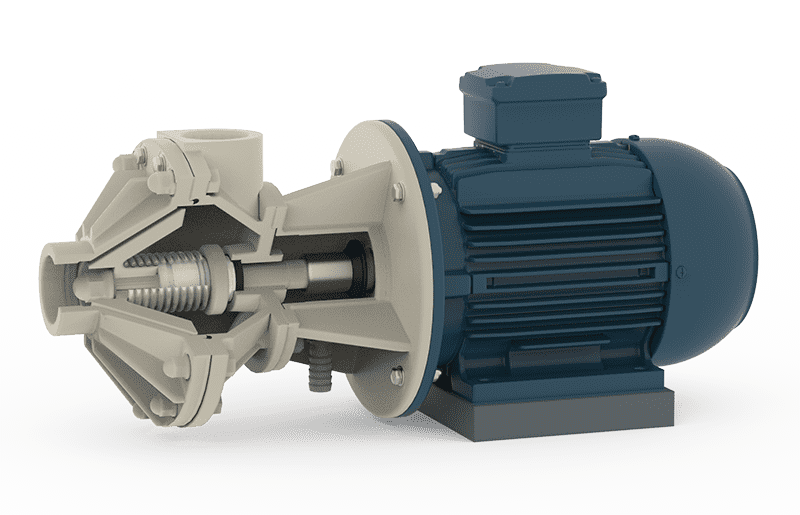

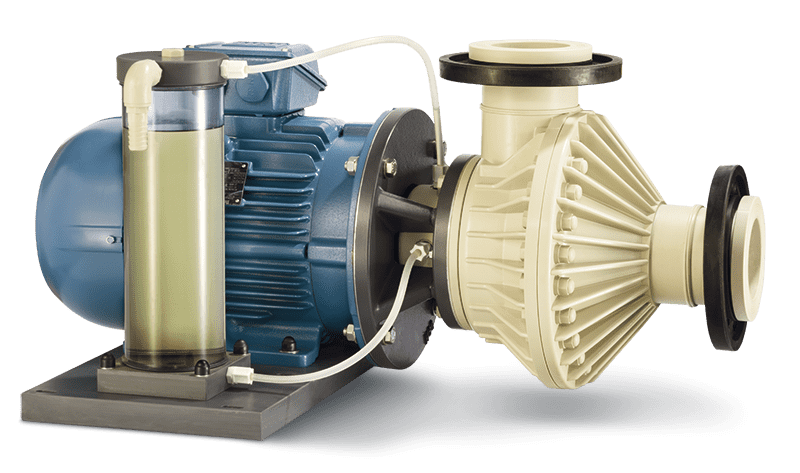

MECHANICALLY SEALED THERMOPLASTIC PUMPS

SINGLE MECHANICAL SEAL

CORROSION-RESISTANT SEAL FOR CHEMICAL APPLICATIONS AND INDUSTRIAL LIQUIDS

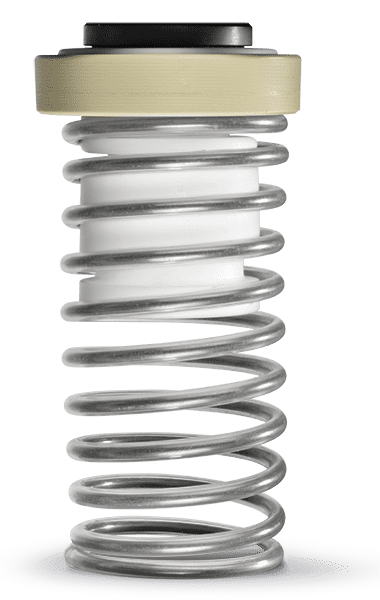

Savino Barbera horizontal chemical pumps are fitted with a mechanical seal made by the company on the basis of many years of experience in the chemical sector. It is a seal for rotating shafts suitable for numerous industrial processes and for working with most aggressive liquids. Designed to be fully resistant to corrosion and wear and tear, the Savino Barbera mechanical seal is reliable even in the presence of other critical situations: dirty liquids, thermal expansion, shaft misalignment, risk of abrasion. It has no metal parts in contact with the liquid and consists of just a few essential elements (sliding rings, bellows, spring). Its modular design allows it to be used not only with corrosive acids but also with slurries and abrasive liquids. It is also completely adjustment-free (it has no screws, locking nuts or covers), making it easy to assemble and maintain, with no need for special skills or tools.

MECHANICAL SEAL MATERIALS

| Static ring | AL2O3 - SIC - filled PTFE - Carbographite |

| Dynamic ring | AL2O3 - SIC - filled PTFE - Carbographite |

| Seal gaskets | EPDM (ethylene-propylene rubber) - FPM (fluorinated rubber) - PTFE (polytetrafluoroethylene) |

| Spring | PFA-coated stainless steel |

| Bellows | PTFE (polytetrafluoroethylene) |

The Savino Barbera mechanical seal is available in different construction materials in order to perfectly meet the requirements of industrial pumping. Its typical configurations, however, are represented by a pair of rings made of Sintered Ceramic (the most common version) or Silicon Carbide (alternative version). The seal rings are also available in a filled PTFE version, but only for special cases. Consequently, the possible combinations between the two sealing faces are more numerous: they are identified on the basis of the operating conditions and the nature of the liquids to be handled. When choosing a mechanical seal, never forget to carefully assess certain factors such as: the risks of chemical reaction and thermal shock, the conductivity and expansion of wetted parts, the friction coefficients and self-lubricating properties of the materials. Our experience, of course, is always useful when it comes to selecting the best seal for the specific case.

THE TWO MAIN CONFIGURATIONS

SILICON CARBIDE

- excellent hardness and wear resistance

- chemically inert

- low friction coefficient

- high resistance to thermal shock

- not suitable for hot caustic solutions

(e.g. concentrated soda)

SINTERED CERAMIC

- high level of hardness and resistance to wear and tear

- excellent resistance to chemical aggression

- not suitable for hydrofluoric acid

- not suitable for severe thermal shocks

- suitable for hot caustic solutions

(e.g. concentrated soda)

download area

HOW IT WORKS

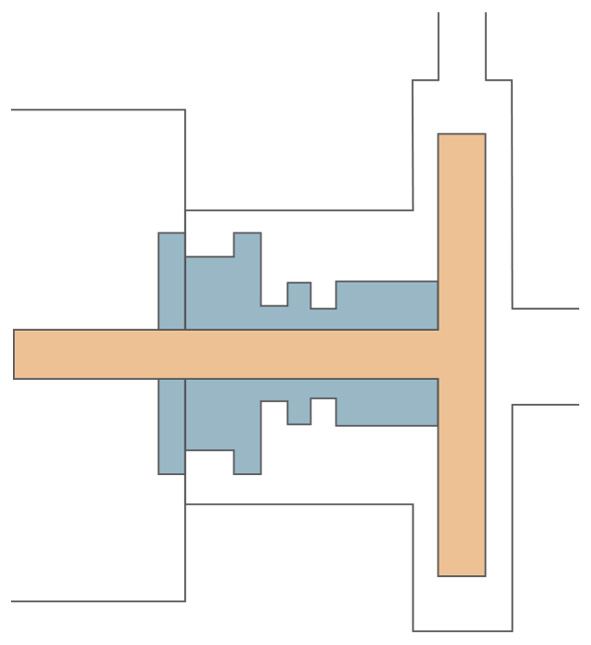

The operation of the mechanical seals is very simple: a rotating ring rubs against another stationary ring, while an axial force ensures contact between these two opposing faces: the adhesion between the faces of the two rings develops the “seal” effect. Like any other mechanical seal for horizontal pumps, the Savino Barbera mechanical seal prevents the liquid from escaping from the pump-shaft inlet hole which has to be present in the pump casing to allow direct coupling of the pump-shaft with the motor-shaft. The mechanical seal of Savino Barbera chemical pumps consists of a rotating part which is attached to the shaft (dynamic ring) and a static part integral which is attached to the pump body (static ring). These two parts remain in constant contact via their respective faces. The static and dynamic rings obviously have surfaces with a very high finish so that they can slide against each other without allowing the liquid to escape. This creates a very thin layer of liquid between the two surfaces, which lubricates the rings and creates the “seal” (hydrodynamic film). But unlike other “commercial” seals, the Savino Barbera mechanical seal is fully resistant to corrosion and is suited to pumping not only aggressive liquids, but also highly charged liquids, liquids with suspended solids, sludge and slurry.

SAVINO BARBERA SEAL: MAIN FEATURES

SELF-CLEANING

Internal assembly increases the cooling of the sliding parts and stabilises the pump during the start and stop phases. Centrifugal rotation removes impurities with a cleaning effect. Furthermore, the housing on the delivery side facilitates visual inspection to allow prompt maintenance.

BALANCED

The use of the bellows as a flexible support transmits rotation to the dynamic ring, ensures the pump shaft seal, improves the distribution of the load on the spring, offsets misalignment or displacement, and maintains coplanar contact between the faces of the seal.

NO ADJUSTMENTS

The Savino Barbera seal is characterised by the absence of screws, locking nuts and covers and requires no adjustment. Its position is defined by a specific seat inside the pump casing (static ring) and by the shank of the impeller (dynamic ring). The result is unparalleled ease of assembly and maintenance.

CHEMICALLY INERT

The bellows is made of PTFE, the metal spring is coated with PFA, the collar can be made of PP, PVC or PVDF, and the gaskets are made of EPDM or FPM. All these plastic materials, fluoro-polymers and rubbers make the Savino Barbera seal chemically inert.

CARATTERISTICHE principali

SELF-CLEANING

Internal assembly increases the cooling of the sliding parts and stabilises the pump during the start and stop phases. Centrifugal rotation removes impurities with a cleaning effect. Furthermore, the housing on the delivery side facilitates visual inspection to allow prompt maintenance.

BALANCED

The use of the bellows as a flexible support transmits rotation to the dynamic ring, ensures the pump shaft seal, improves the distribution of the load on the spring, offsets misalignment or displacement, and maintains coplanar contact between the faces of the seal.

NO ADJUSTMENTS

The Savino Barbera seal is characterised by the absence of screws, locking nuts and covers and requires no adjustment. Its position is defined by a specific seat inside the pump casing (static ring) and by the shank of the impeller (dynamic ring). The result is unparalleled ease of assembly and maintenance.

CHEMICALLY INERT

The bellows is made of PTFE, the metal spring is coated with PFA, the collar can be made of PP, PVC or PVDF, and the gaskets are made of EPDM or FPM. All these plastic materials, fluoro-polymers and rubbers make the Savino Barbera seal chemically inert.

SPECIAL VERSION: WITH DOUBLE SEAL

ABILITY TO PUMP WITHOUT LIQUID (DRY RUNNING)

The horizontal axis pumps manufactured by Savino Barbera can also be fitted with a double mechanical seal. Every one of our horizontal chemical pumps with a single mechanical seal can always be transformed into a double mechanical seal, without major alterations to its external structure. This special configuration is ideal, for example, for the safe filling/emptying of tankers, for pumping certain difficult liquids (caustic soda, ferrous sulphate, ferric chloride or other corrosive liquids) or to contrast any vaporisation of the liquid between the faces of the seal. A double mechanical seal is more commonly used when the pump can be accidentally started without liquid and there is a risk of dry running. Pictured: OMA100A in PP with double seal, ideal for contrasting solidification the formation of scale due to the pumping of sodium sulphate.

DO YOU HAVE A REQUEST ?

WRITE TO OUR STAFF