HORIZONTAL CHEMICAL PUMPS

CORROSION-RESISTANT HORIZONTAL PUMPS

Horizontal centrifugal pumps made entirely of corrosion-resistant plastic. With no metal parts in contact with the liquids being pumped, they are suitable for pumping acids and aggressive solutions, even in extreme operating conditions. They are equipped with a mechanical seal designed exclusively by Savino Barbera, incorporating years of experience in the chemical industry.

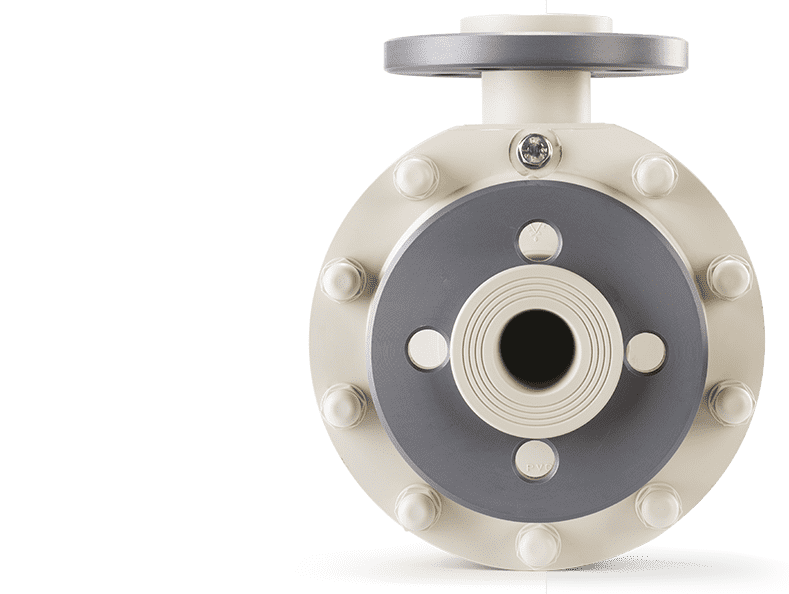

OMA SERIES: COMPACT DESIGN

OMA Series close-coupled horizontal pumps. With their compact design, these pumps are compatible with numerous corrosive products used in industrial processes and chemical plants. Max flow rate 90 m³/h. Max head 55 m w.c. Plastic construction materials: PP, PVC, PVDF.

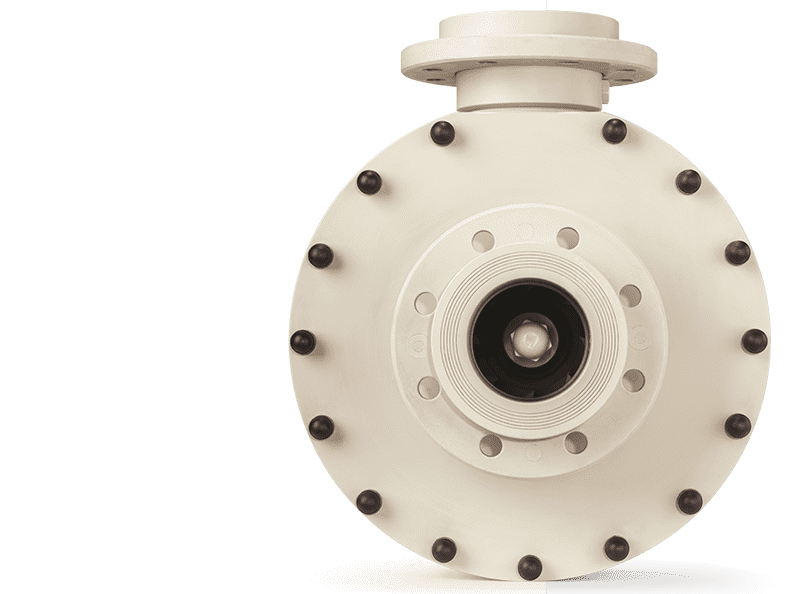

OP SERIES: HIGH FLOW RATES

OP Series horizontal pumps. Machined from solid blocks of polypropylene and equipped with motors with extra support, these are robust chemical pumps ideal for heavy duty operations. Max flow rate 200 m³/h. Max head 42 m w.c. Plastic construction material: PP.

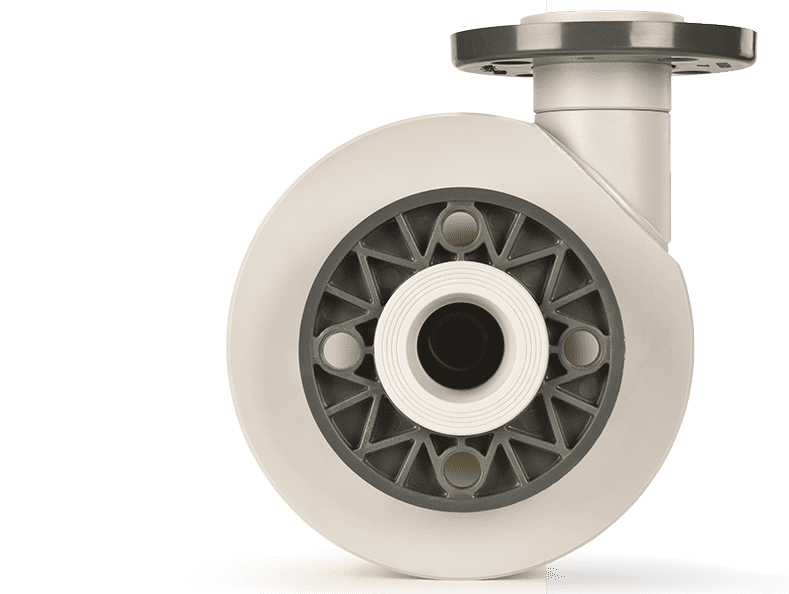

OA SERIES: FOR DIRTY LIQUIDS

OA Series horizontal pumps. With anti-clogging impellers and large internal spaces, they can pump even very dirty industrial liquids (containing solid fibres and other coarse impurities). Max flow rate 32 m³/h. Max head 20 m w.c. Plastic construction materials: PP, PVC, PVDF.

PA SERIES: SELF-PRIMING

PA Series self-priming horizontal pumps. With negative suction (maximum negative head: 4 m). Not suitable for dense, viscous, hot liquids and with high vapour tension. Max flow rate 280 l/min. Max head 15 m w.c. Plastic construction materials: PP, PVC, PVDF.

OMA SERIES: COMPACT DESIGN

OMA Series close-coupled horizontal pumps. With their compact design, these pumps are compatible with numerous corrosive products used in industrial processes and chemical plants. Max flow rate 90 m³/h. Max head 55 m w.c. Plastic construction materials: PP, PVC, PVDF.

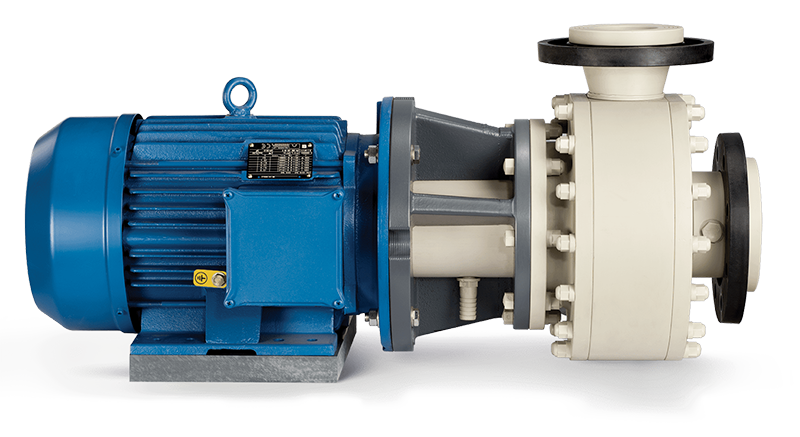

OP SERIES: HIGH FLOW RATES

OP Series horizontal pumps. Machined from solid blocks of polypropylene and equipped with motors with extra support, these are robust chemical pumps ideal for heavy duty operations. Max flow rate 200 m³/h. Max head 42 m w.c. Plastic construction materials: PP.

OA SERIES: FOR DIRTY LIQUIDS

OA Series horizontal pumps. With anti-clogging impellers and large internal spaces, they can pump even very dirty industrial liquids (containing solid fibres and other coarse impurities). Max flow rate 32 m³/h. Max head 20 m w.c. Plastic construction materials: PP, PVC, PVDF.

PA SERIES: SELF-PRIMING

PA Series self-priming horizontal pumps. With negative suction (maximum negative head: 4 m). Not suitable for dense, viscous, hot liquids and with high vapour tension. Max flow rate 280 l/min. Max head 15 m w.c. Plastic construction materials: PP, PVC, PVDF.

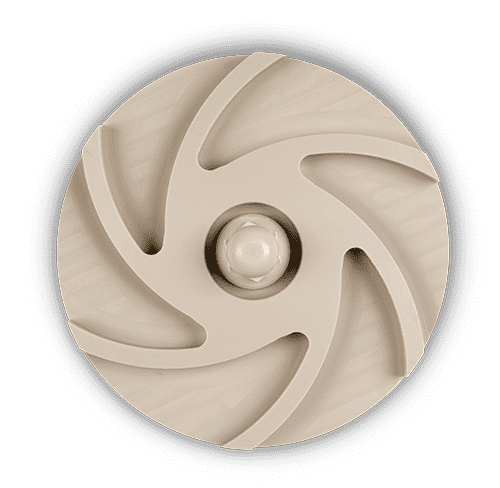

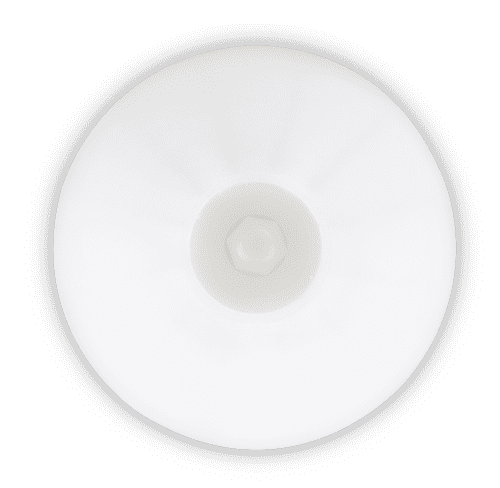

SAVINO BARBERA MECHANICAL SEAL

Savino Barbera horizontal pumps have a very strong heart: a corrosion-resistant mechanical seal that withstands wear and tear. It is a seal flushed by the liquid pumped and suitable for working with most aggressive liquids. Its simplicity is disarming: it is made up of a spring, a bellows and two sliding rings that develop the sealing effect. Furthermore, it requires no screws or other special tools to be used or mounted: basically, it’s harder to describe it than to use it!

THERMOPLASTIC MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of anti-acid centrifugal pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

PVC (POLYVINYL CHLORIDE)

Plastic material with an excellent resistance to acids, bases, saline solutions and organic compounds. PVC is generally used for pumping sodium hypochlorite (NaClO). At low temperatures it becomes fragile. The operating temperature is between 40 and 60°C.

PVDF (POLYVINYLDENFLUORIDE)

Fluorinated thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

OTHER STRENGTHS

- Compact design, ideal for reduced industrial spaces.

- Essential components easily disassembled over time.

- Maintenance with no need for special skills or tools.

- Spare parts are available even years after the original supply.

OTHER STRENGTHS

- Compact design, ideal for reduced industrial spaces.

- Essential components easily disassembled over time.

- Maintenance with no need for special skills or tools.

- Spare parts are available even years after the original supply.