MECHANICALLY SEALED THERMOPLASTIC PUMPS

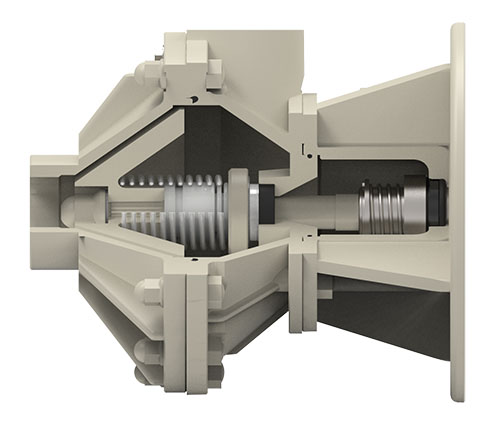

DOUBLE MECHANICAL SEAL

PARTICULAR CASES FOR USE OF HORIZONTAL PUMPS WITH A DOUBLE MECHANICAL SEAL

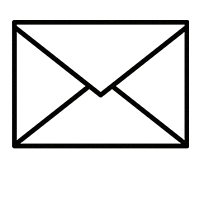

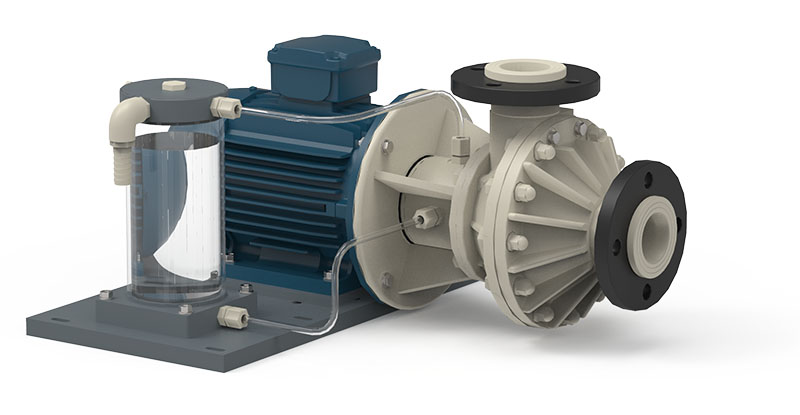

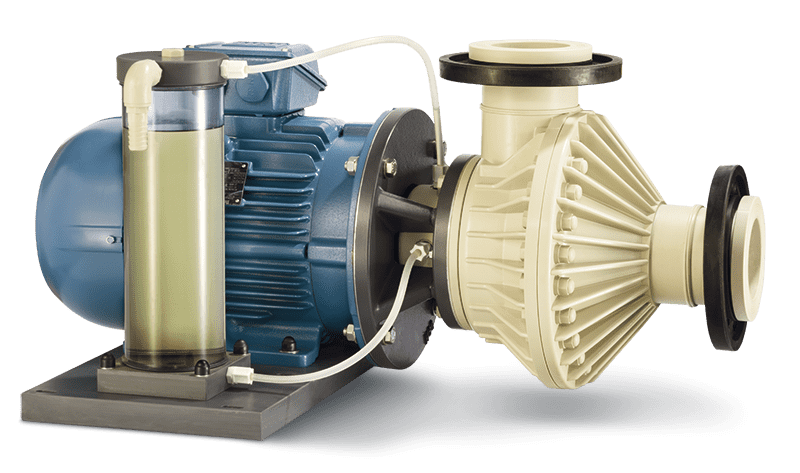

Our horizontal chemical pumps are also available with a double mechanical seal, flushed with compatible auxiliary liquids. With this “standard” execution, the traditional characteristics of the Savino Barbera mechanical seal (product side) join the additional benefits offered by an extra conventional seal (atmosphere side). Equipped with a non-pressurised auxiliary circuit (supplied by an external source or a recirculation tank), the dual seal allows Savino Barbera thermoplastic pumps to work without difficulty in the absence of liquid or in the presence of other critical conditions. This configuration in tandem, facilitates the pumping of liquids at low temperatures, liquids which tend to crystallise, liquids with oxides or solid deposits, by contrasting any sticking of the seal faces. In short, for Savino Barbera horizontal pumps, the adoption of a double seal represents an additional element of safety against unexpected leaking of liquid or accidental dry starts.

DOUBLE MECHANICAL SEAL MATERIALS

Primary mechanical seal (product side)

| Static ring |

AL2O3 - SIC - filled PTFE - Carbographite |

Dynamic ring |

AL2O3 - SIC - filled PTFE - Carbographite |

Seal gaskets |

EPDM (ethylene-propylene rubber) - FPM (fluorinated rubber) - PTFE (polytetrafluoroethylene) |

Spring |

PFA-coated stainless steel |

Bellows |

PTFE (politetrafluoroetilene) |

Secondary mechanical seal (atmosphere side) | Static ring |

Carbographite (carbon graphite) |

Dynamic ring |

Stainless steel 316 |

Seal gaskets |

EPDM (ethylene-propylene rubber) |

Spring |

Stainless steel 316 |

Seeger |

Stainless steel 316 |

| ||

The Savino Barbera standard mechanical seal is available in different construction materials in order to perfectly meet the requirements of industrial pumping. Its typical configurations, however, are represented by a pair of rings made of Sintered Ceramic (the most common version) or Silicon Carbide (alternative version). The seal rings are also available in a filled PTFE version, but only for special cases. Consequently, the possible combinations between the two sealing faces are more numerous: they are identified on the basis of the operating conditions and the nature of the liquids to be handled. When choosing a mechanical seal, never forget to carefully assess certain factors such as: the risks of chemical reaction and thermal shock, the conductivity and expansion of wetted parts, the friction coefficients and self-lubricating properties of the materials. Our experience, of course, is always useful when it comes to selecting the best seal for the specific case.

DOUBLE MECHANICAL SEAL: THE TWO POSSIBLE VERSIONS

CLOSED CIRCUIT

The circulation of the auxiliary fluid of the double seal can also be achieved via recirculation from a small external non-pressurised tank, usually mounted alongside the pump on a rigid PVC baseplate (regardless of the size of the pump). In this case, the fluid is supplied and circulated through the closed circuit of the chamber, where the auxiliary liquid remains constantly. A typical application of this forced circulation is the use of antifreeze fluid as a barrier fluid (when pumping liquids subject to sudden cooling and freezing). Like the open circuit, the closed circuit is obviously also a valid protection against the risk of dry-running.

OPEN CIRCUIT

20 ÷ 30 l/h, and be at ambient temperature if possible (it is therefore advisable to avoid hard water and/or industrial water). When the pump is not working, the circulation chamber must always be kept full of liquid.

download area

DRY RUNNING AND OTHER ADVANTAGES

The Savino Barbera double mechanical seal is used successfully when it is necessary to deal with liquids characterised by particular phenomena (vaporisation or crystallisation), when pumping operations require additional safety precautions (emptying tankers, railway wagons, tanker ships) or when the risk of “dry running” is very high for other reasons (idle pump left without liquid). The benefits of adopting a secondary seal (mounted in a circulation chamber) reflect directly on the main mechanical seal (mounted inside the pump casing).

- Protection against accidental overrunning in the absence of liquid.

- Barrier against the passage of air through the seal rings.

- Elimination of sticking of the seal faces, when the pump is idle or empty.

- Pumping of liquids with temperatures close to boiling point.

- Pumping of concentrated hydrochloric acid (prevents damage from acid vapour).

- Low-temperature operations (use of the pump in case of frost).

- Tanker filling/emptying phase (corrects operation without liquid).

- Pumping liquids with crystals, oxides, deposits (eliminates liquid/air contacts).

- Use of pumps left without liquid (prolonged storage, occasional use).

- Copper or nickel baths treatments (prevents solidification).

KEY CHARACTERISTICS

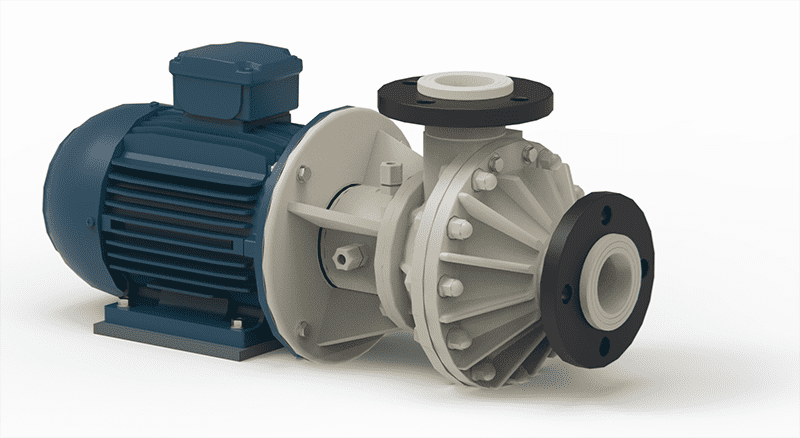

TANDEM CONFIGURATION

The two mechanical seals are mounted in the same direction. The primary seal ensures sealing of the liquid pumped (product side) while the secondary seal is used to seal the auxiliary liquid (atmosphere side).

CHEMICAL COMPATIBILITY

Water fulfils the function of an auxiliary liquid well. It is still necessary to check the compatibility between the liquid pumped and the auxiliary liquid to exclude contamination, dilution, exothermic chemical reactions and pollution. The only possible interchange is from the liquid pumped to the auxiliary liquid.

BARRIER LIQUID

The auxiliary liquid separates, washes, cools and condenses the vapours. It is circulated at a pressure slightly higher than atmospheric pressure but below that of the liquid pumped.

DRY RUNNING

The double flushed seal is suitable for operations where there is a high risk of dry starting or running, such as in the filling and emptying of tankers: the auxiliary circuit allows pumping without inconvenience, even if the liquid no longer reaches the pump.

CARATTERISTICHE principali

TANDEM CONFIGURATION

The two mechanical seals are mounted in the same direction. The primary seal ensures sealing of the liquid pumped (product side) while the secondary seal is used to seal the auxiliary liquid (atmosphere side).

CHEMICAL COMPATIBILITY

Water fulfils the function of an auxiliary liquid well. It is still necessary to check the compatibility between the liquid pumped and the auxiliary liquid to exclude contamination, dilution, exothermic chemical reactions and pollution. The only possible interchange is from the liquid pumped to the auxiliary liquid.

BARRIER LIQUID

The auxiliary liquid separates, washes, cools and condenses the vapours. It is circulated at a pressure slightly higher than atmospheric pressure but below that of the liquid pumped.

DRY RUNNING

The double flushed seal is suitable for operations where there is a high risk of dry starting or running, such as in the filling and emptying of tankers: the auxiliary circuit allows pumping without inconvenience, even if the liquid no longer reaches the pump.

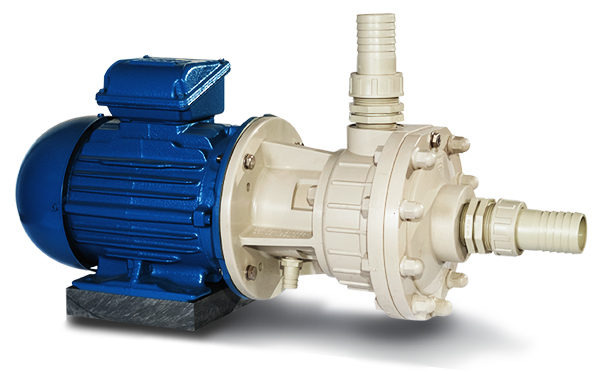

STANDARD VERSION: WITH SINGLE SEAL

CORROSION-RESISTANT SEAL FOR CHEMICAL APPLICATIONS AND INDUSTRIAL LIQUIDS

All standard versions of Savino Barbera horizontal chemical pumps are fitted with a single mechanical seal made by the company on the basis of many years of experience in the chemical sector. It is an internal mechanical seal lubricated by the liquid pumped and suitable for working with most aggressive liquids. Designed to be resistant to corrosion and wear and tear, the Savino Barbera mechanical seal is reliable even in the presence of other critical situations: dirty liquids, thermal expansion, shaft misalignment, risk of abrasion. It has no metal parts in contact with the liquid and consists of just a few essential elements (sliding rings, bellows, spring). It is also completely adjustment-free (it has no screws, locking nuts or covers), making it easy to assemble and maintain, with no need for special skills or tools.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS