CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

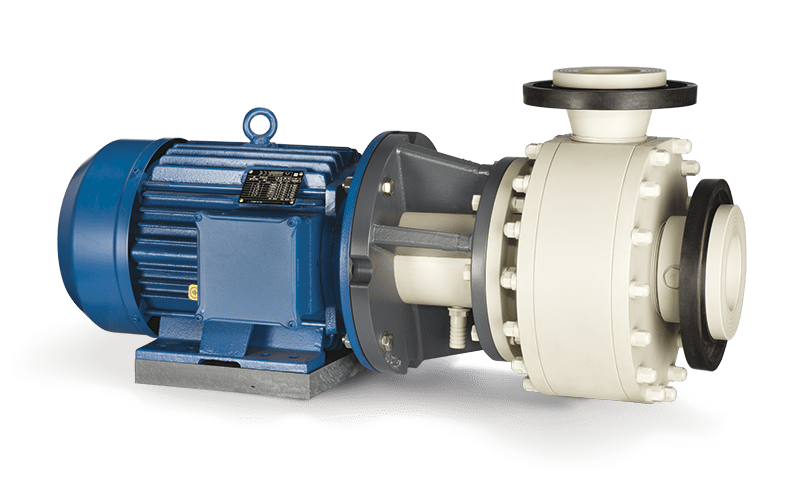

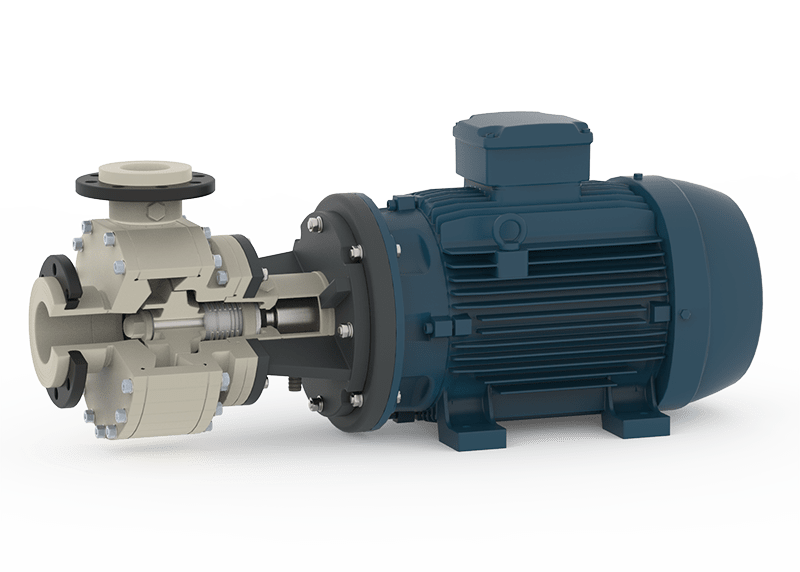

OP HORIZONTAL PUMPS

CORROSION-RESISTANT CHEMICAL PUMPS. WITH MECHANICAL SEAL. FOR AGGRESSIVE LIQUIDS, BOTH ACID AND ALKALINE, CLEAN INDUSTRIAL FLUIDS AND THOSE WITH VARIOUS KINDS OF IMPURITIES. IDEAL FOR CONTINUOUS SERVICES AND HEAVY-DUTY OPERATIONS.

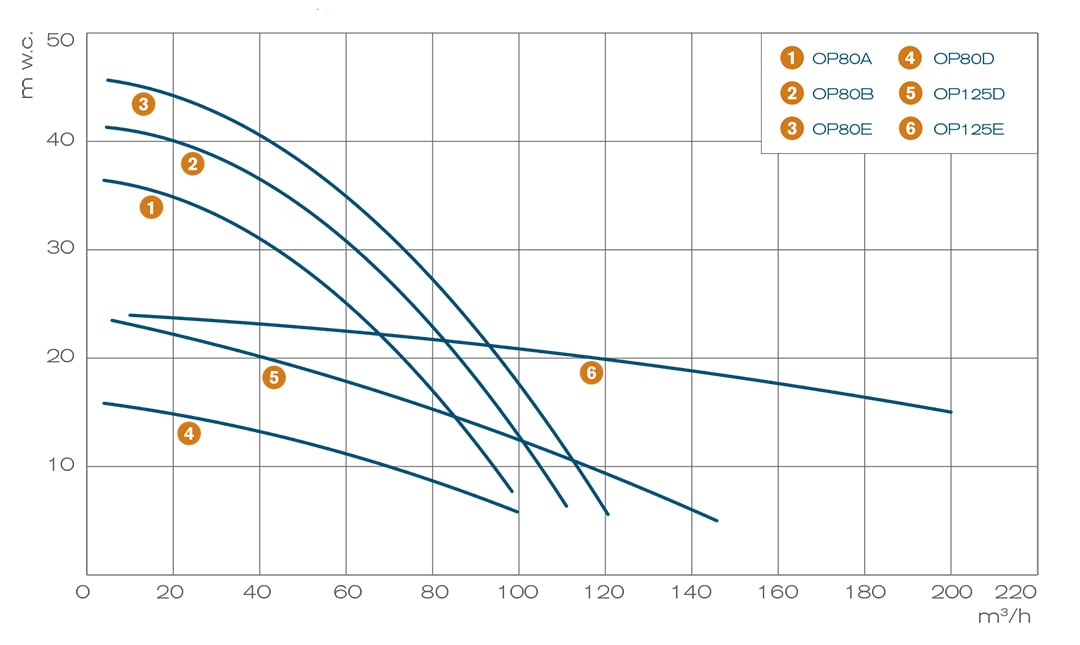

- Maximum flow rate: 200 m³/h.

- Maximum head: 42 m w.c.

- Thermoplastic construction materials: PP.

- With no metal parts in contact with chemical liquids.

- Mechanical seal made of silicon carbide (SiC).

- Pumps for under flooded installations.

- Suction/delivery: flange (DN80 or DN100).

TECHNICAL INFORMATION

Standard curves: 50 Hz (60 Hz curves available on request). A-B series: open impeller. D series: 4-pole motor. E series: 2 or 4-pole motor. The curves refer to tests with cold, clean water and a density of 1000 kg/m3 (ISO9906). Hydraulic performance may change in relation to changes in the characteristics of the liquid to be pumped.

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

STRENGTHS

LESS METAL, LESS CORROSION

Horizontal pumps machined from a solid block of polypropylene (PP). All parts that come into contact with liquid (wetted parts), including nuts and bolts, are insensitive to corrosion.

ANTI-ACID PERFORMANCE

The anti-acid performance of Savino Barbera chemical pumps comprises casings, covers, impellers, shafts, mechanical seal and nuts and bolts. Just a few elements, which can always be easily removed.

CAST-IRON MOTORS

Space-saving close-coupled plastic pumps. Equipped with cast-iron electric motors suitable for continuous running and heavy-duty operations.

EXTREMELY ROBUST

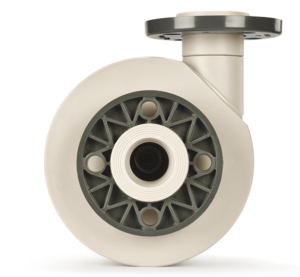

OP pumps are structurally and chemically very robust. Thanks to their flat plastic impellers and thick-walled plastic body, not only are they resistant to corrosion, they are also not affected by dirty liquids or high temperatures.

STRENGTHS

LESS METAL, LESS CORROSION

Horizontal pumps machined from a solid block of polypropylene (PP). All parts that come into contact with liquid (wetted parts), including nuts and bolts, are insensitive to corrosion.

ANTI-ACID PERFORMANCE

The anti-acid performance of Savino Barbera chemical pumps comprises casings, covers, impellers, shafts, mechanical seal and nuts and bolts. Just a few elements, which can always be easily removed.

CAST-IRON MOTORS

Space-saving close-coupled plastic pumps. Equipped with cast-iron electric motors suitable for continuous running and heavy-duty operations.

EXTREMELY ROBUST

OP pumps are structurally and chemically very robust. Thanks to their flat plastic impellers and thick-walled plastic body, not only are they resistant to corrosion, they are also not affected by dirty liquids or high temperatures.

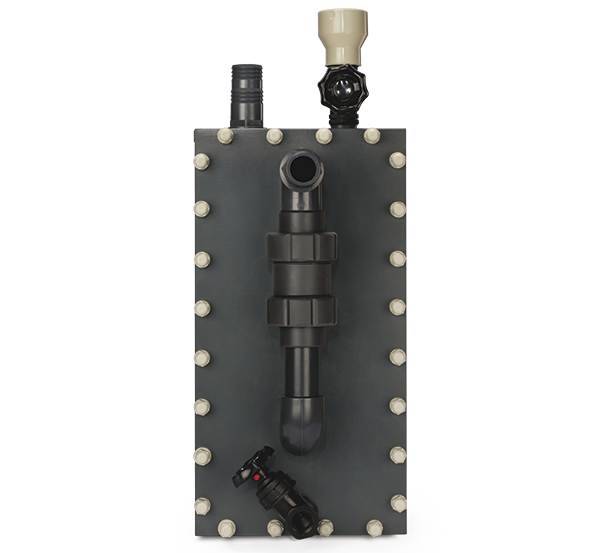

MECHANICAL SEAL

OP pumps are fitted with a mechanical seal resistant to corrosion and wear and tear, compatible with most industrial liquids. This seal is the product of years of experience working with chemicals and consists of just a few elements: a coated spring, a bellows made of PTFE and two sliding rings that create the seal. It has no metal parts in contact with aggressive liquids. Furthermore, it requires no special adjustments or tools to be used or mounted: simplicity is its strength!

THE DETAILS THAT MAKE THE DIFFERENCE

POLYPROPYLENE

The plastic construction material used to make OP chemical pumps is polypropylene (PP), a thermoplastic used extensively with industrial fluids which offers good resistance to most acid and alkaline solutions. Polypropylene can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

MECHANICAL SEAL

OP horizontal pumps are fitted with a corrosion-resistant mechanical seal designed exclusively by Savino Barbera. It is an internal mechanical seal, balanced with bellows independent of the direction of rotation. It is flushed by the liquid being pumped. The material used as standard, for the OP series only, is usually silicon carbide (SiC).

EXTRA THICK

OP chemical pumps are engineered for harshest of environments and for continuous running (even 24 hours a day). They are suitable for a variety of industrial applications, including wet cleaning towers, scrubbers, deodorising systems, fume and odour control systems, ash inertisation plants and evaporation towers.

FOR DEMANDING OPERATIONS

The horizontal chemical pumps of the OP series are equipped with cast-iron motors with oversized bearings (double row angular contact ball bearings) and PP fans resistant to acid vapours. These qualities make them particularly well-suited to heavy-duty services and continuous operations.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST HORIZONTAL PUMPS SUPPLIES

OP80B HORIZONTAL PUMP

Corrosion resistant polypropylene pump for concentrated sulfuric acid (40%). Mechanical seal made from Ceramic.

HEAVY-DUTY OPERATIONS PUMP

Chemical pump for removing hydrochloric acid fumes from a pickling acid storage tank at a steel plant.

OP80B 18.5 KW CHEMICAL PUMP

Non metallic mechanically sealed pump with thick-walled casings for added strengh and temperature resistance.

FURTHER PLASTIC HORIZONTAL PUMPS