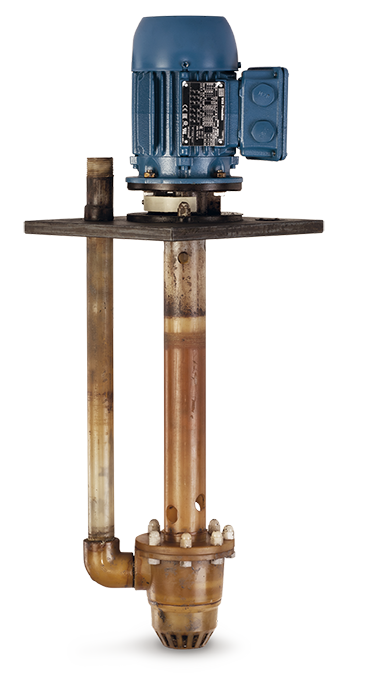

CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

AS VERTICAL PUMPS

Corrosion-resistant plastic pumps. For pumping aggressive liquids, slightly charged industrial fluids, chemicals and acid solutions.

- Chemical resistant plastic pumps.

- Maximum flow rate: 90 m³/h.

- Maximum head: 55 m w.c.

- Plastic construction materials: PP, PVC, PVDF.

- With no metal parts in contact with chemical liquids.

- Custom-made lengths between 200 and 3000 mm.

- One-piece shaft with no intermediate bearings.

- Wear bushings made of filled-PTFE, SiC, Ceramic.

- Assembly in tank: no leaking.

TECHNICAL INFORMATION

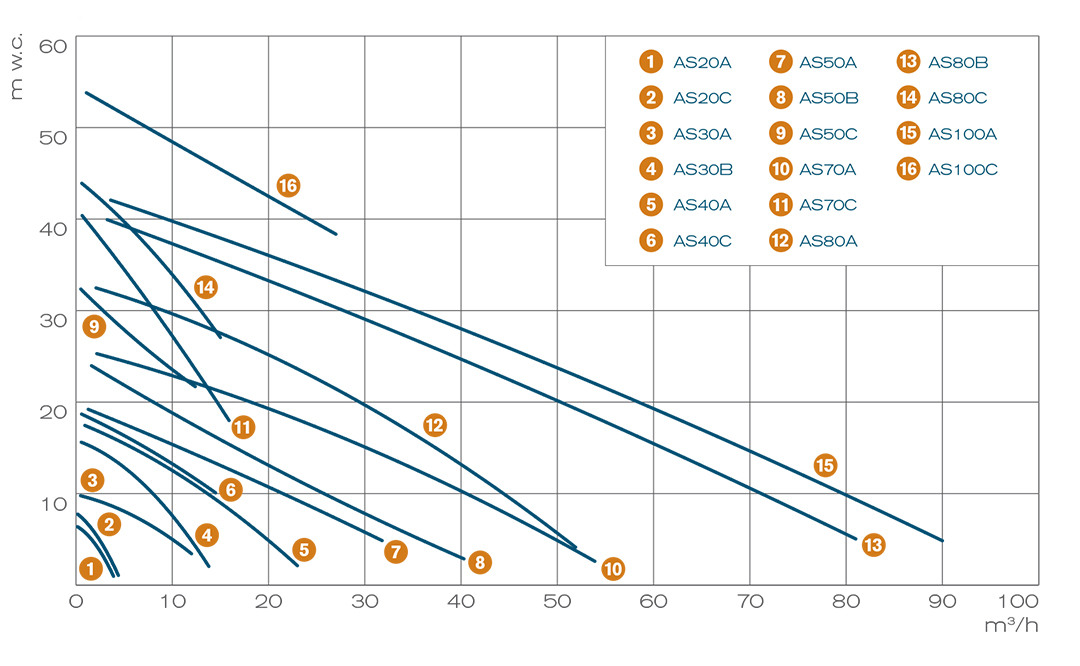

Standard curves: 50 Hz (60 Hz curves available on request). A-B series: open impeller. C series: closed impeller. The curves refer to tests with cold, clean water and a density of 1000 kg/m³ (ISO9906). Hydraulic performance may change in relation to changes in the characteristics of the liquid to be pumped.

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

STRENGTHS

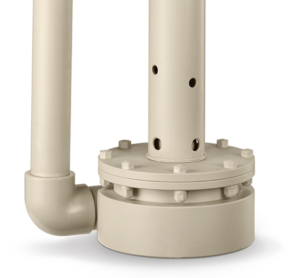

LESS METAL, LESS CORROSION

AS vertical pumps are made of corrosion-resistant thermoplastic material (PP, PVC, PVDF). All parts that come into contact with liquid are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The anti-acid performance of our pumps also comprises nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coatings (PP, PVC, PVDF). Savino Barbera design eliminates the contact of metal with aggressive liquids.

END-BUSHINGS

Pair of bushings with direct flushing, with no need for external lubrication. The sliding bushings are proposed in different corrosion and abrasion-resistant materials, depending on the aggressive liquid to be pumped.

MODULAR DESIGN

Construction without predefined lengths up to 3000 mm. Extra thick PVC support plates, also available in custom-made shapes and sizes. Connections: flange, thread or hose adapter.

CHEMICAL RESISTANCE

Structural parts moulded or machined from a solid block. Some components are ribbed to offer better mechanical stability and unconditional chemical resistance. Pump casings with internal gaps to allow the passage of coarse solids.

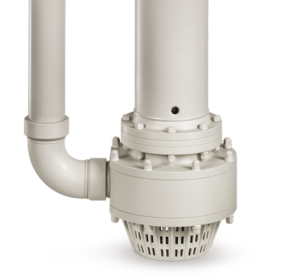

PLASTIC IMPELLERS

Plastic impellers with no metal inserts, resistant to attack from acids, even on the inside. Their conical configuration protects shaft and bushings from radial stress, conveying structural stability to the pump.

STRENGTHS

LESS METAL, LESS CORROSION

AS vertical pumps are made of corrosion-resistant thermoplastic material (PP, PVC, PVDF). All parts that come into contact with liquid are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The anti-acid performance of our pumps also comprises nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coatings (PP, PVC, PVDF). Savino Barbera design eliminates the contact of metal with aggressive liquids.

END-BUSHINGS

Pair of bushings with direct flushing, with no need for external lubrication. The sliding bushings are proposed in different corrosion and abrasion-resistant materials, depending on the aggressive liquid to be pumped.

MODULAR DESIGN

Construction without predefined lengths up to 3000 mm. Extra thick PVC support plates, also available in custom-made shapes and sizes. Connections: flange, thread or hose adapter.

CHEMICAL RESISTANCE

Structural parts moulded or machined from a solid block. Some components are ribbed to offer better mechanical stability and unconditional chemical resistance. Pump casings with internal gaps to allow the passage of coarse solids.

PLASTIC IMPELLERS

Plastic impellers with no metal inserts, resistant to attack from acids, even on the inside. Their conical configuration protects shaft and bushings from radial stress, conveying structural stability to the pump.

CHEMICAL APPLICATIONS

- Chemical and petrochemical systems

- Electroplating baths

- Pickling lines, galvanisation

- Metal wire treatment

- Fume and odour control

- Scrubbers and washing towers

- Seawater treatment

- Demineralisation plants

- Acid water neutralisation

- Purification plants

- Recovery of precious metals

- Production of batteries

- Regeneration units

- Production of fertilisers

- Industrial logistics of fluids

- Wastewater pumping

THE DETAILS THAT MAKE THE DIFFERENCE

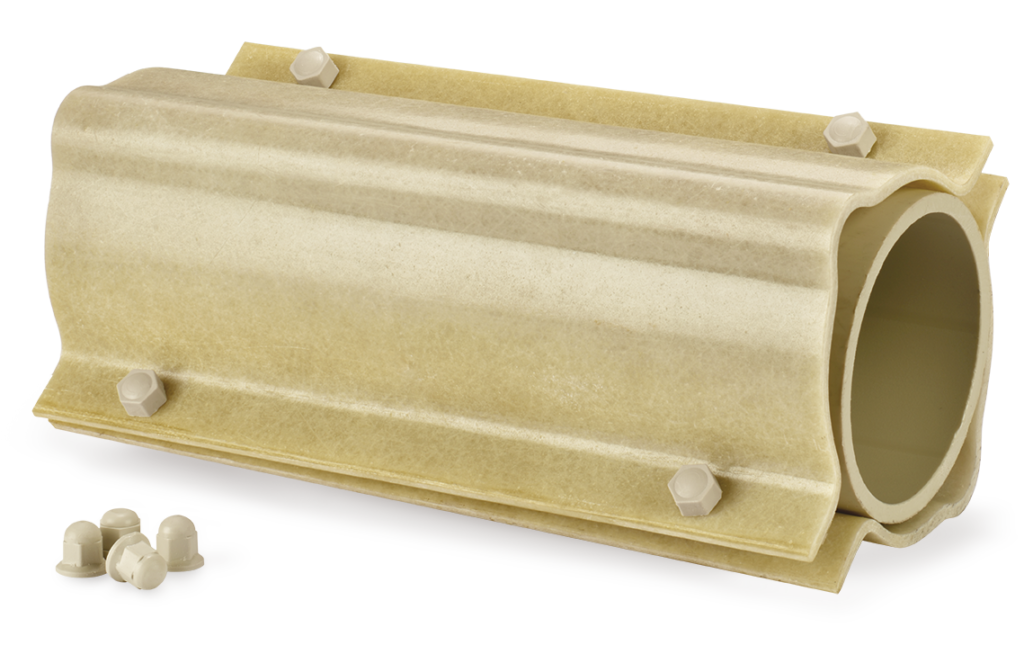

REINFORCEMENT IN FIBREGLASS

From lengths of 2000 mm upwards, Savino Barbera vertical pumps have aluminium motor supports, oversized shafts and fibreglass outer structures. This is a construction solution that ensures additional resistance to vibrations while protecting the pump from other mechanical or thermal stress.

IMMERSED BEARINGS

AS pumps have no intermediate bearings, even in the longer versions (3000 mm). The only guide element consists of a pair of wear bushings positioned at the end of the pump shaft. The bushings are available in materials suited to chemical liquids, fluids containing sludge or suspended solids: filled-PTFE, sintered ceramic or silicon carbide.

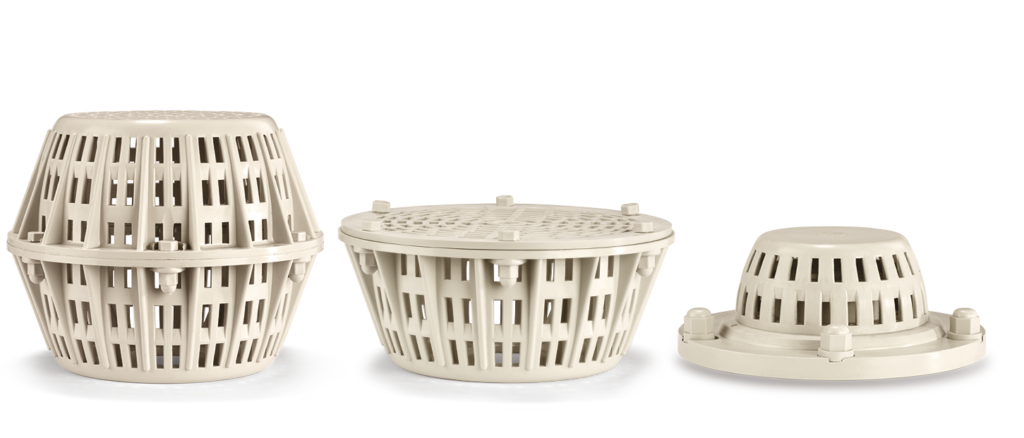

FILTERS AND EXTENSIONS

AS pumps can be fitted with suction extensions to reach extra lengths of 4 metres. They can also be equipped with filters to trap coarse impurities; the grill prevents the suction of residues or foreign bodies that are often found in industrial liquids. The filters are also available in a flat version to reduce the occupation of the bottom of the tank.

CORROSIVE LIQUIDS

- Nitric acid

- Muriatic acid

- Citric acid

- Brine

- Ammonia

- Caustic potash

- Chemical fertilisers

- Fertilisers

- Glycerine, glycol

- Fuels and biodiesel

- Solvents of various kinds

- Seawater

- Sulphuric acid

- Caustic soda

- Hydrochloric acid

- Sodium hydroxide

- Chromic acid

- Sodium hypochlorite

- Hydrofluoric acid

- Ferric chloride

- Aluminium polychloride

- Phosphoric acid

- Flocculants

- Polyelectrolytes

- Urea and AdBlue

- Sanitising gels

- Inks, dyes, paints

- Industrial oils

- Cosmetic liquids

- Industrial detergents

- Acetic acid

- Distilled water

- Demineralised water

- Hydrogen peroxide

- And your liquid, of course!

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST VERTICAL PUMPS SUPPLIES

CUSTOM-MADE VERTICAL PUMPS

Tailor-made vertical chemical pumps designed to meet the specific dimension of each installation tank.

PVC VERTICAL CENTRIFUGAL PUMPS

AS30 vertical thermoplastic pumps made in PVC (polyvinyl chloride). For sulfuric acid and sodium hypochlorite.

VERTICAL PUMPS UP TO 3000 MM

Polypropylene pumps in lengths up to 3000 mm. Suitable for deeper sumps through the use of tail pipes.

CHEMICAL PUMP FOR CHROMIC ACID

Vertical pump with fluid contact components fabricated in PVDF for chromic acid with a temperature of 60°C.

THERMOPLASTIC ANTI-ACID PUMP

Plastic pumps commonly used for chemical transfer duties where corrosive liquids, caustics, alkalis are involved.