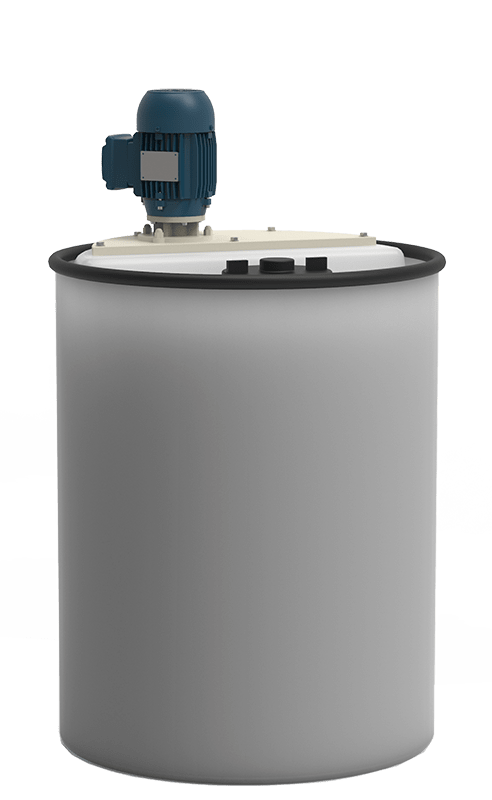

CHEMICAL MIXING UNITS: MIXER+TANK

AN/AR+DS MIXING STATIONS

CHEMICAL MIXING SYSTEMS CONSISTING OF CORROSION-FREE MIXERS AND STANDARD SIZE POLYETHYLENE TANKS. FOR MIXING, BLENDING, DISSOLVING, HOMOGENISING, KEEPING IN SUSPENSION CORROSIVE LIQUIDS, CHEMICAL SOLUTIONS, FERTILISERS AND OTHER AGRICULTURALLY RELATED CHEMICALS.

- High resistance to chemical aggression.

- With AN or AR top-entry mixers.

- With mixing tanks with capacities from 60 to 1040 litres.

- For vigorous or gentle mixing.

- 4-6-8-pole motors. Also available with gearmotors.

- Mixer materials: PP, PVC, PVDF, AISI 304.

- Tank material: corrosion-resistant PE.

- Operating temperatures between -20C and + 60C°.

AN SERIES MIXERS + TANKS

In the AN+DS series, mixers made of the following materials can be fitted inside the tanks: PP, PVC, PVDF, AISI 304.

We also supply special custom-made mixers. Please contact our technical department for any special requirements.

AR SERIES MIXERS + TANKS

In the AR+DS series, mixers made of steel (AISI 304) are usually fitted inside the tanks:

We also supply special custom-made mixers. Please contact our technical department for any special requirements.

download area

THE TWO MODELS

AN+DS MIXING STATIONS

High-speed direct drive mixers coupled to polyethylene mixing tanks. With three-blade marine impeller. Materials: PP, PVC, PVDF, AISI 304. Maximum tank capacity: 1040 litres.

AN+DS MIXING STATIONS

High-speed direct drive mixers coupled to polyethylene mixing tanks. With three-blade marine impeller. Materials: PP, PVC, PVDF, AISI 304. Maximum tank capacity: 1040 litres.

AR+DS MIXING STATION

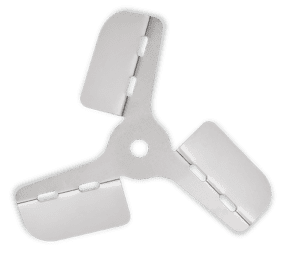

Geared slow-speed mixers coupled to polyethylene mixing tanks. With high-efficiency three-blade impeller. Materials: PP, PVC, PVDF. Maximum tank capacity: 1040 litres.

AR+DS MIXING STATION

Geared slow-speed mixers coupled to polyethylene mixing tanks. With high-efficiency three-blade impeller. Materials: PP, PVC, PVDF. Maximum tank capacity: 1040 litres.

WHAT’S INSIDE: PLASTIC MIXERS

Plastic mixers with direct drive cantilever shaft. All wetted parts (shaft and impeller) are made of corrosion-resistant plastic (PP, PVC, PVDF). They are particularly suitable for liquid-solid or liquid-liquid mixing and mixing liquids with solids in suspension. Fast rotation (1400 rpm max).

CONSTRUCTION MATERIALS

PP

The most widely used

anti-acid plastic polymer for use in corrosive environments. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, up to a temperature of 80°C.

PVC

Plastic material with excellent resistance to acids, bases, saline solutions and organic compounds. PVC is generally used when treating sodium hypochlorite (NaClO).

At low temperatures it becomes fragile. The operating temperature is between 40 and 60°C.

PVDF

Thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but

is ideal for highly concentrated acids.It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

AISI 304

AN mixers are also available in stainless steel. This version can be used to mix industrial liquids that are not particularly aggressive, such as: fertilisers, manures, quenching treatments, wastewater, graphite suspensions, mineral oils. Maximum operating temperature: approx. 100°C

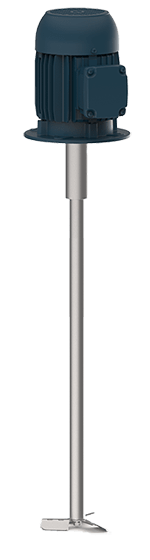

WHAT’S INSIDE: METAL MIXERS

Plastic mixers with direct drive cantilever shaft. All wetted parts (shaft and impeller) are made of stainless steel (AISI 304). Ideal for liquids that are not highly corrosive, such as: solvents, essences, fertilisers, pesticides, herbicides, manures, surfactants, quenching treatments, water and graphite. Fast rotation (1400 rpm max).

WHAT’S INSIDE: METAL MIXERS

Plastic mixers with direct drive cantilever shaft. All wetted parts (shaft and impeller) are made of stainless steel (AISI 304). Ideal for liquids that are not highly corrosive, such as: solvents, essences, fertilisers, pesticides, herbicides, manures, surfactants, quenching treatments, water and graphite. Fast rotation (1400 rpm max).

WHAT’S OUTSIDE: THE ACCESSORIES

Drainage valve

Containment tank

Fixed frame

Mobile frame

WHAT’S INSIDE: SLOW-SPEED MIXERS

Slow-speed geared mixers with completely cantilevered shaft. All wetted parts (shaft and impeller) are made of chemically-resistant themoplastic (PP, PVC, PVDF). Used typically when gentle mixing of the liquid is required (as in the case of water flocculation where the flakes cannot be subjected to high turbulence). Characterised by clockwise rotation when looking from the motor side: the flow generated is always downward.

FERTIGATION

FRAMES, VALVES, CONTAINMENT TANKS

Depending on the operating conditions, our mixing stations can be equipped with various optional features, including: metal lifting frame, transportable trolley-mounted frames, drainage valves, double containment tanks.

FERTIGATION

FRAMES, VALVES, CONTAINMENT TANKS

Depending on the operating conditions, our mixing stations can be equipped with various optional features, including: metal lifting frame, transportable trolley-mounted frames, drainage valves, double containment tanks.

EXAMPLE OF

CHEMICALS

- Nitric acid

- Phosphoric acid

- Hydrochloric acid

- Chlorine and derivatives

- Sulphuric acid

- Nitrogen, phosphorus, potassium

- Nitrate, phosphate, sulphate

Examples of application

- Acidification and neutralisation of water

- Fertigation systems

- Dissolution of salts in liquids

- Denitrification processes

- Preparation of polyelectrolyte solutions

- Chlorination systems

- Preparation of chemical reagents

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST INDUSTRIAL MIXERS SUPPLIES

STANNOUS SULFATE AND MORE

Chemical mixing unit equipped with termoplastic mixer for blending silver nitrate, sulfuric acid, stannous sulfate.

CONE BOTTOM TANKS

Mixing station comes with slow-speed mixer made in polypropylene for agitating water, ice and salt.

CORROSIVE CHEMICAL LIQUIDS

Mixing unit consisting of standard size plastic tank and corrosion free mixer for chemical applications.

COPPER SULFATE AND MORE

High speed top entry mixer for water, copper sulfphate and sulfuric acid. Tank with transportable metal frame.

FERRIC CHLORIDE & NITRIC ACID

Mixing unit with stirrer made in for a solution of ferric chloride and nitric acid. Equipped with wheeled chassis.

VISCOUS PASTE MIXING

Chemical holding tank with AR50 mixer. For mixing viscous polishing paste with max viscosity of 500 cps.

MIXER FOR COSMETICS INDUSTRY

Chemical mixing station comes with with dual impeller metal agitator and mobile frame. For cosmetic liquids.

FURTHER INDUSTRIAL MIXERS