CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

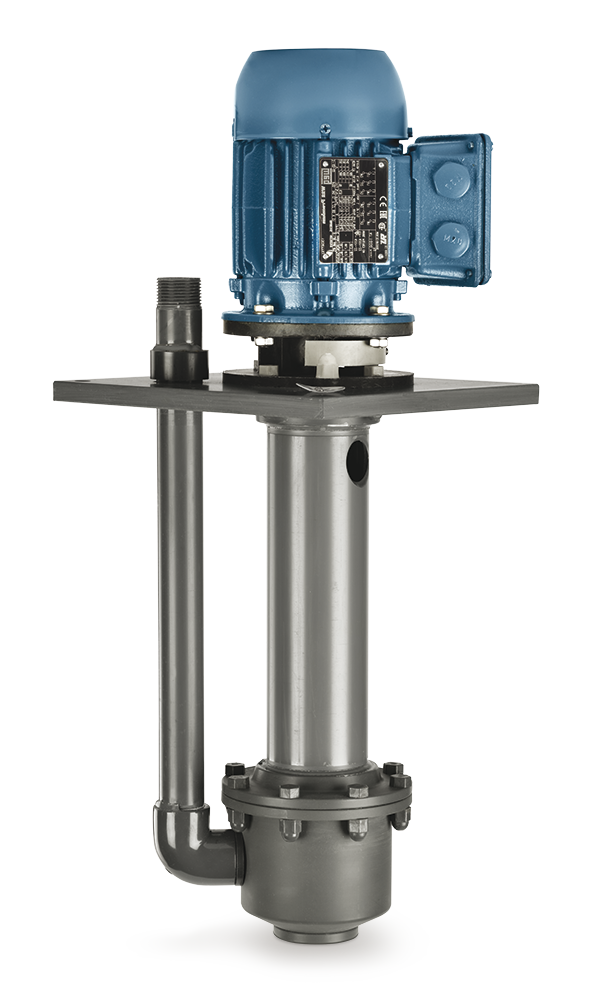

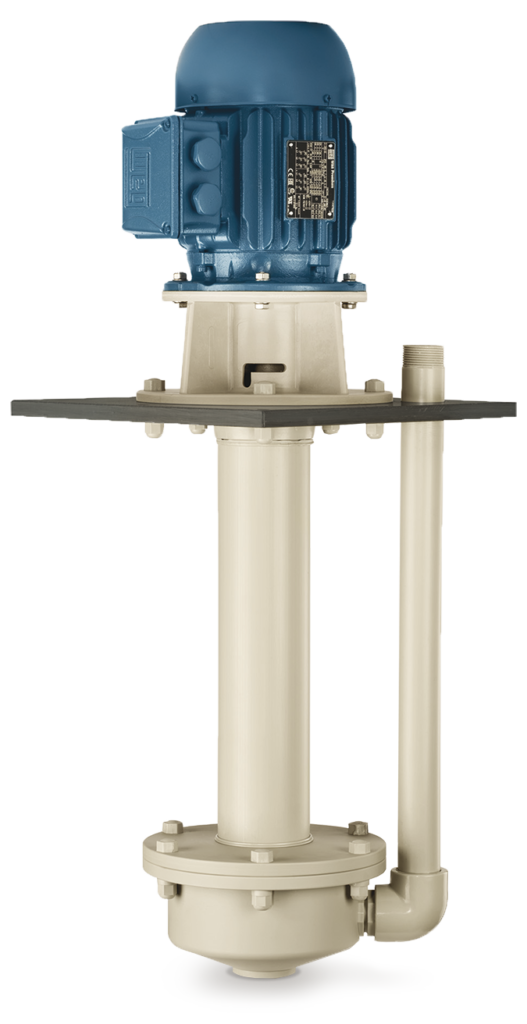

BS VERTICAL PUMPS

CORROSION-RESITANT PLASTIC PUMPS WITHOUT BUSHINGS. FOR PUMPING SLIGHTLY ABRASIVE LIQUIDS, LIQUIDS CONTAINING SUSPENDED SOLIDS OR FLUIDS THAT TEND TO CRYSTALLIZE OR FORM SCALE.

- Corrosion-resistant chemical pumps.

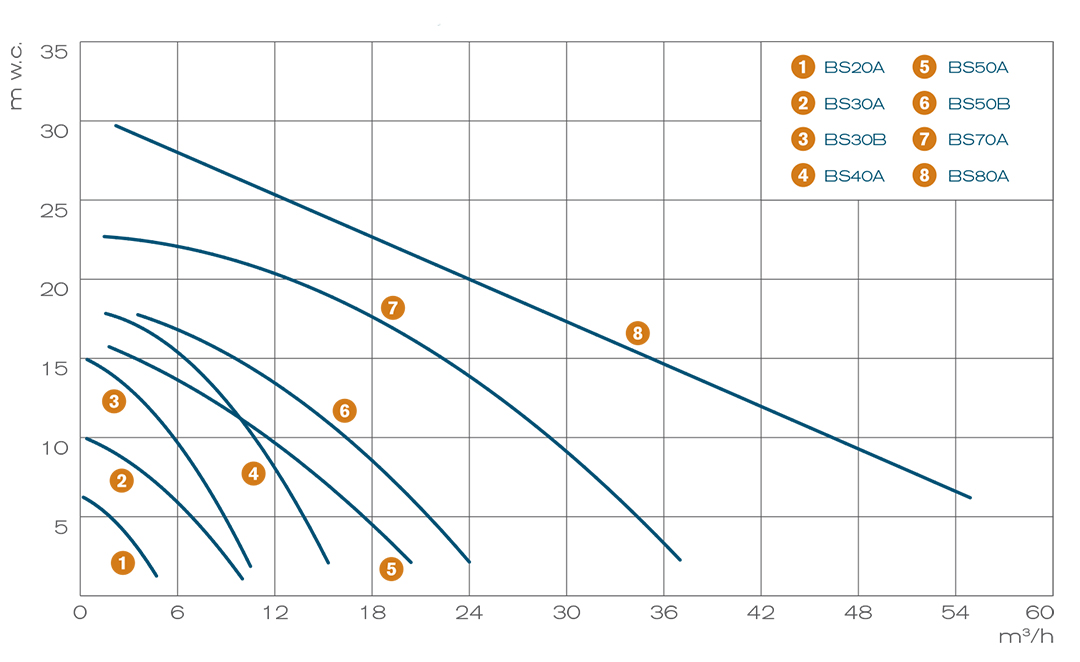

- Maximum flow rate: 55 m³/h.

- Maximum head: 30 m w.c.

- Thermoplastic construction materials: PP, PVC, PVDF.

- With no metal parts in contact with chemical liquids.

- Made in four standard lengths: 400, 550, 700, 900 mm.

- Cantilever shaft with no bushings or bearings (cantilever pumps).

TECHNICAL INFORMATION

| Q max m³/h | H max m w.c. | kW | rpm 50 Hz | length | Datasheet | |

|---|---|---|---|---|---|---|

| BS20A | 5 | 6 | 0.25 - 0.37 | 2900 | 400 mm | |

| BS30A | 10 | 10 | 0.55 - 0.75 | 2900 | 550 mm | |

| BS30B | 10 | 10 | 1.1 - 1.5 | 2900 | 550 mm | |

| BS40A | 15 | 18 | 2.2 | 2900 | 550 mm | |

| BS50A | 20 | 18 | 2.2 - 3 | 2900 | 700 mm | |

| BS50B | 24 | 18 | 3 - 4 | 2900 | 700 mm | |

| BS70A | 37 | 25 | 5.5 - 7.5 | 2900 | 900 mm | |

| BS80A | 55 | 31 | 7.5 - 9.5 | 2900 | 900 mm |

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

OVERALL DIMENSIONS

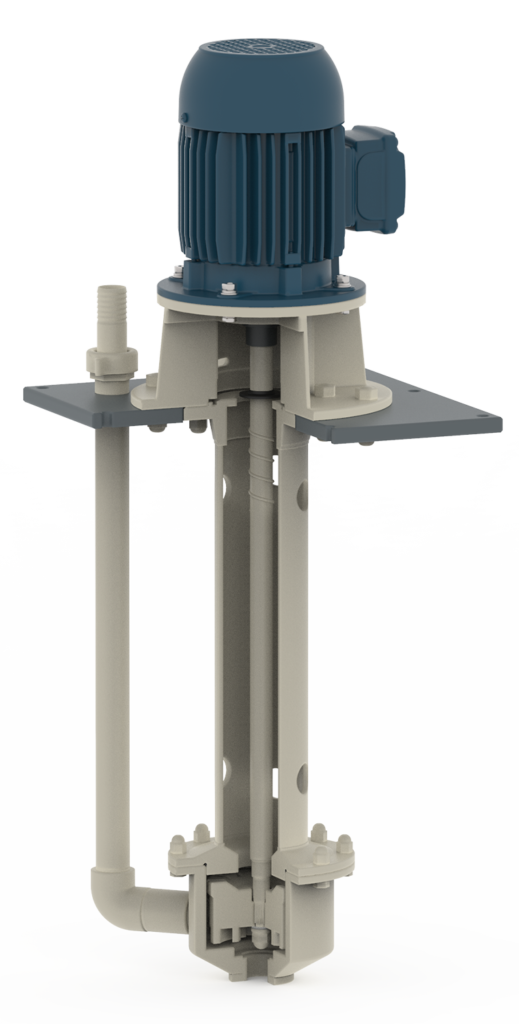

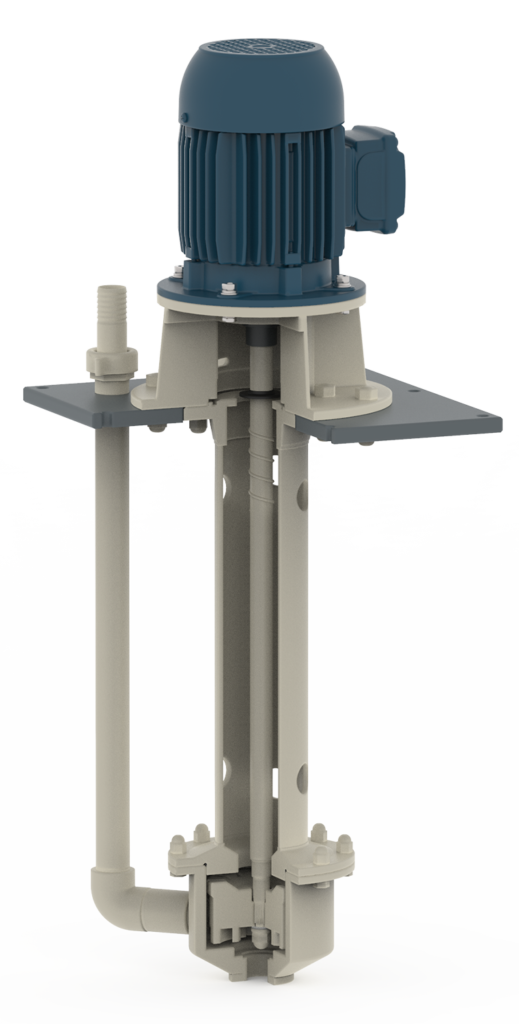

SECTIONAL DRAWINGS

STRENGTHS

LESS METAL, LESS CORROSION

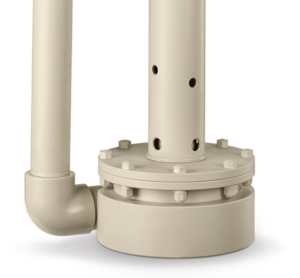

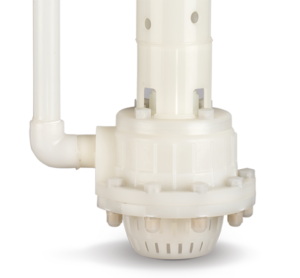

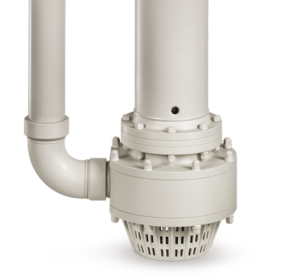

BS vertical pumps are made of corrosion-resistant thermoplastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The anti-acid performance of our pumps also comprises all nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coatings (PP, PVC, PVDF). Savino Barbera design eliminates the contact of metal with aggressive liquids.

CANTILEVER PUMPS

BS series chemical pumps have no intermediate supports or wear bushings: their cantilevered shafts are coupled directly to the motor.

FOUR LENGTHS

BS vertical pumps have no intermediate supports or end bushings: their cantilevered shafts are made in 4 fixed sizes (400, 550, 700, 900 mm), with the possibility to add extra suction pipes.

FOR SOLIDS-LANDING LIQUIDS

Due to the complete absence of sliding bushings, BS pumps are suitable for handling liquids containing abrasive particles, sludge, fluids containing suspensions or with a tendency to form scale.

PLASTIC IMPELLERS

Double-acting impellers made of thermoplastic material with no metal inserts: the impellers of Savino Barbera pumps cannot be attacked by acids, not even on the inside.

LESS METAL, LESS CORROSION

BS vertical pumps are made of corrosion-resistant thermoplastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The anti-acid performance of our pumps also comprises all nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coatings (PP, PVC, PVDF). Savino Barbera design eliminates the contact of metal with aggressive liquids.

CANTILEVER PUMPS

BS series chemical pumps have no intermediate supports or wear bushings: their cantilevered shafts are coupled directly to the motor.

FOUR LENGTHS

BS vertical pumps have no intermediate supports or end bushings: their cantilevered shafts are made in 4 fixed sizes (400, 550, 700, 900 mm), with the possibility to add extra suction pipes.

FOR SOLIDS-LANDING LIQUIDS

Due to the complete absence of sliding bushings, BS pumps are suitable for handling liquids containing abrasive particles, sludge, fluids containing suspensions or with a tendency to form scale.

PLASTIC IMPELLERS

Double-acting impellers made of thermoplastic material with no metal inserts: the impellers of Savino Barbera pumps cannot be attacked by acids, not even on the inside.

CHEMICAL APPLICATIONS

- Chemical and petrochemical systems

- Electroplating baths

- Pickling lines, galvanisation

- Metal wire treatment

- Fume and odour control

- Scrubbers and washing towers

- Seawater treatment

- Demineralisation plants

- Acid water neutralisation

- Purification plants

- Recovery of precious metals

- Production of batteries

- Regeneration units

- Production of fertilisers

- Industrial logistics of fluids

- Wastewater pumping

THERMOPLASTIC MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of anti-acid centrifugal pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.0°C.

PVC (POLYVINYL CHLORIDE)

Plastic material with an excellent resistance to acids, bases, saline solutions and organic compounds. PVC is generally used for pumping sodium hypochlorite (NaClO). At low temperatures it becomes fragile. The operating temperature is between 40 and 60°C.

PVDF (POLYVINYLDENFLUORIDE)

Fluorinated thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

ABRASION AND CRYSTALLISATION

BS pumps are cantilever pumps characterised by the absence of sliding parts (bushings or intermediate bearings); a completely cantilevered pump-shaft coupled directly to the motor makes these pumps perfect for liquids containing particles or abrasive sludge, with a very high risk of becoming worn. BS pumps are suitable for tanks in which the level of liquid is constant. They can be equipped with an extra suction pipe to extend the immersion length.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST VERTICAL PUMPS SUPPLIES

PUMP FOR SOLIDS-LADEN LIQUID

Cantilever vertical pump with no submerged bushings capable to handling liquids containing solids or abrasive slurries.

CANTILEVERED BEARINGLESS PUMP

PVDF chemical pump with no bearings in contact with the corrosive liquid (solution of chromic acid and sulfuric acid).

FOR HANDLING CAUSTIC SODA

BS30 chemical pumps in polypropylene for water with sodium hydroxide (galvanizing and copper plating baths).