CORROSION-RESISTANT PUMPS AND MIXERS

THERMOPLASTIC MATERIALS

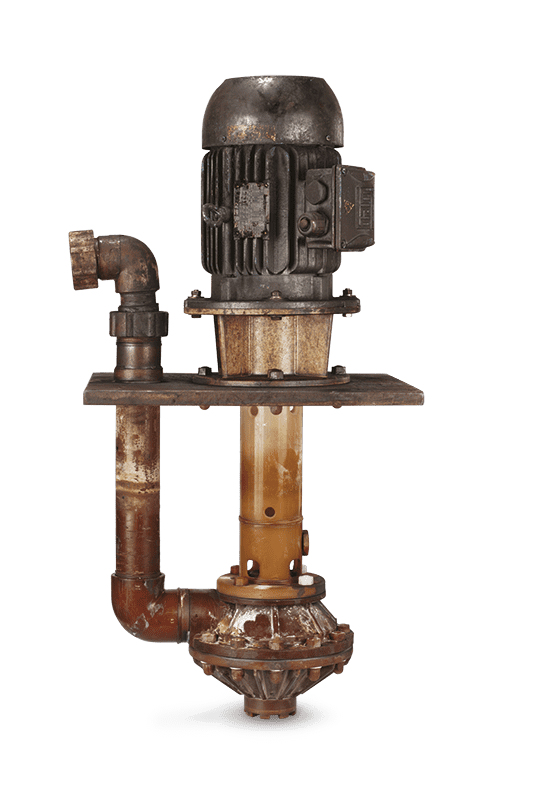

THE SAVINO BARBERA PUMP DESIGN AVOIDS HAVING METAL COMPONENTS IN FLUID CONTACT

When handling hazardous fluids or industrial liquids, the main hazard is usually corrosion. This is why we have replaced metal with plastic and protected the few components that have to be made of metal (for obvious reasons relating to mechanical support) with chemically inert material: all the wetted parts of our pumps and mixers are made entirely of thermoplastics or coated with technical polymers, making them insensitive to chemical aggression. The main corrosion-resistant plastics that we use to manufacture our industrial equipment are PP, PVC and PVDF.

PP (POLYPROPYLENE)

Thermoplastic polymer which offers good resistance to most acid and alkaline solutions. Characterised by valid mechanical properties and high resistance to chemical agents, this plastic material is widely used in the manufacture of industrial components: thanks to its extensive chemical compatibility, it is most likely the most widely used technical material in the construction of our pumps and mixers. It is not suitable for strongly oxidizing concentrated acids and for halogens (fluorine, chlorine, bromine, iodine). Maximum operating temperature: between 60 and 80°C.

PVC (POLYVINYL CHLORIDE)

Savino Barbera is one of the few manufacturers in the world to supply a wide range of pumps and mixers made entirely of PVC, a plastic material with an excellent response to corrosion. PVC is very resistant to acids, bases, saline solutions and organic compounds: it is particularly suitable for sodium hypochlorite. It should not be used for aromatic and chlorinated hydrocarbons. Polyvinyl chloride has some limitations from a thermal point of view and at low temperatures it becomes fragile. The maximum operating temperature is usually 60°C. In some cases, however, it cannot exceed the limit of 40°C.

PVDF (POLYVINYLDENFLUORIDE)

PVDF is a high-performance fluorinated thermoplastic with a wide range of uses. It has exceptional resistance to acids, saline solutions, hydrocarbons, oxidising agents, alcohols and halogens. Suitable for the semiconductor industry and for highly concentrated acids. PVDF is not suitable for certain inorganic bases (such as caustic soda), for alkaline solutions, ketones, esters and ethers. Its maximum operating temperature cannot exceed 100°C.

RIGOROUS SELECTION OF MATERIALS

The plastic materials used in the construction of all our products are meticulously selected on the basis of the characteristics of the corrosive liquid treated. The ability to select the most appropriate thermoplastic material is one of Savino Barbera’s main skills: our choice is always functional to the specific use that the equipment we produce is intended for. In order to determine which plastic is chemically compatible with the liquid to be pumped (PP, PVC or PVDF), it is necessary to have a precise idea of the chemical and physical characteristics of the liquid to be handled. Every plastic material has a different chemical compatibility with the various corrosive liquids. The fundamental data for selecting the material of the wetted parts of the pump (those that come into contact with the liquid) are: chemical nature, concentration, temperature, specific weight, possible presence of solids. A small example: different concentrations of the same acid may require different plastic materials.

KEY CHEMICAL APPLICATIONS

- Chemical and petrochemical systems

- Electroplating baths

- Pickling, galvanisation

- Metal wire treatment

- Fume and odour control

- Scrubbers and washing towers

- Seawater treatment

- Purification, demineralisation

- Acid water neutralisation

- Purification plants

- Recovery of precious metals

- Production of batteries and accumulators

- Production of fertilisers

- Industrial logistics of fluids

- Wastewater pumping

OTHER CONSTRUCTION MATERIALS

MECHANICAL SEAL: CERAMIC, SIC, PTFA, CARBOGRAPHITE

For all our horizontal pumps, we have designed and made a mechanical seal resistant to corrosion and abrasion (with no metal parts in contact with liquids). It is made up of just three elements: a plastic-coated spring, a bellows and two sliding rings. The spring of the seal is coated with PFA (a chemical-resistant fluoropolymer with low permeability) while the bellows are made of PTFE: both are chemically inert materials that withstand use with the most aggressive acids. Its seals are made of EPDM or FPM. The mating rings (static and dynamic ring) can be made of sintered ceramic, silicon carbide, filled-PTFE or Carbographite. The seal rings are available in these various combinations in order to meet different industrial pumping requirements. For these reasons, the Savino Barbera mechanical seal shows excellent tribological behaviour even in the presence of critical situations such as thermal expansion, risk of abrasion and shaft misalignment. Its modular design and ease of use allow its use not only with corrosive acids but also with slurries and abrasive liquids.

GUIDE BUSHINGS: PTFE, CERAMIC, SIC

DIAPHRAGMS: PLASTIC, RUBBER, PTFE

MAGNETS: NEODYMIUM IRON AND BORON PERMANENT MAGNETS

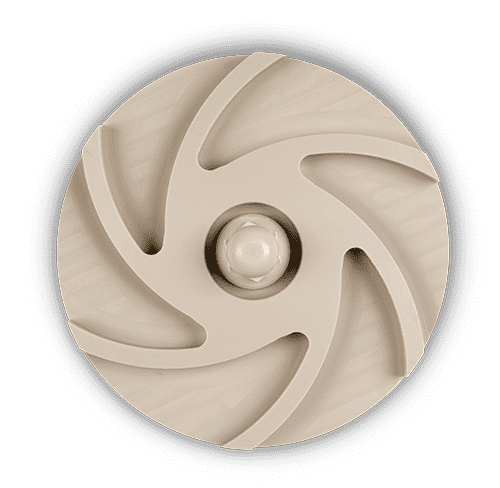

Savino Barbera mag-drive pumps are characterised by closed impellers and plastic-coated magnetic couplings. Pump construction materials: anti-acid plastic (PP and PVDF) and metal (AISI 316, HASTELLOY). Encapsulated magnetic materials: neodymium iron and boron permanent magnets (NeFeBo). Static shaft materials: Al2O3 99.7% (BM series plastic pumps), SiC – Al2O3 – RSSiC (DM70 plastic pumps) and Hastelloy C276 (metal pumps). Materials O-ring: EPDM or VITON. Sliding bushing materials: filled-PTFE, graphite. Please note that magnetic pumps are sensitive to harsh operating conditions. Their limitation continues to be the pumping of clean liquids, without suspended solids.

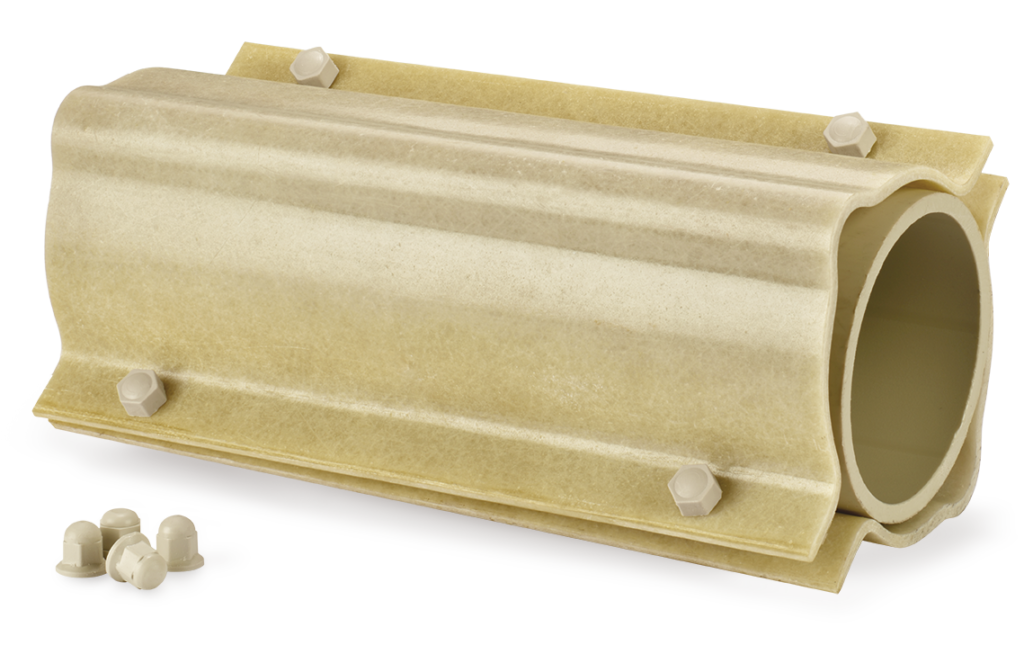

REINFORCEMENT IN FIBREGLASS

All AS series vertical pumps with sizes over 2000 mm are structurally reinforced by two opposing sections made of glass fibre-reinforced plastic (GFRP). In this type of chemical centrifugal pump, the thermoplastic support column is reinforced by a fibreglass structure that adds extra stability to the pumping unit. Fibreglass is a thermo-hardening compound material consisting of a glass-fibre reinforced polymer matrix and is universally known for its mechanical properties and chemical resistance. Thanks to its excellent qualities of lightness and strength, this external reinforcement made of fibreglass conveys the right solidity to our vertical pumps, which are able to work in perfect conditions, even with considerable lengths.

PLASTIC COATED NUTS AND BOLTS

The nuts and bolts used by Savino Barbera in its chemical pumps and industrial mixers have a moulded plastic coating (PP, PVC, PVDF). This anti-acid thermoplastic coating completely insulates the metal of the nuts and bolts from all contamination by acid liquids or vapours. The thermoplastic material is obviously selected on the basis of chemical compatibility with the corrosive liquids treated and is limited to surfaces not affected by the threaded coupling. If the nuts and bolts are immersed in the fluid being pumped, PTFE washers are required. The metal components of the nuts and bolts are made of stainless steel and brass: the alternating use of two different metals guarantees a steel/brass coupling that doesn’t seize up or become stuck, simplifying disassembly over time.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS