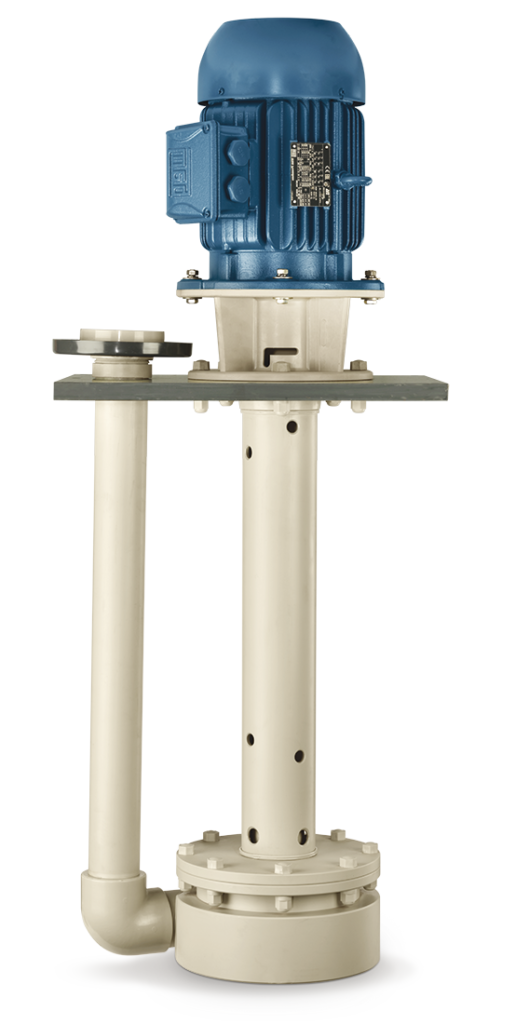

CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

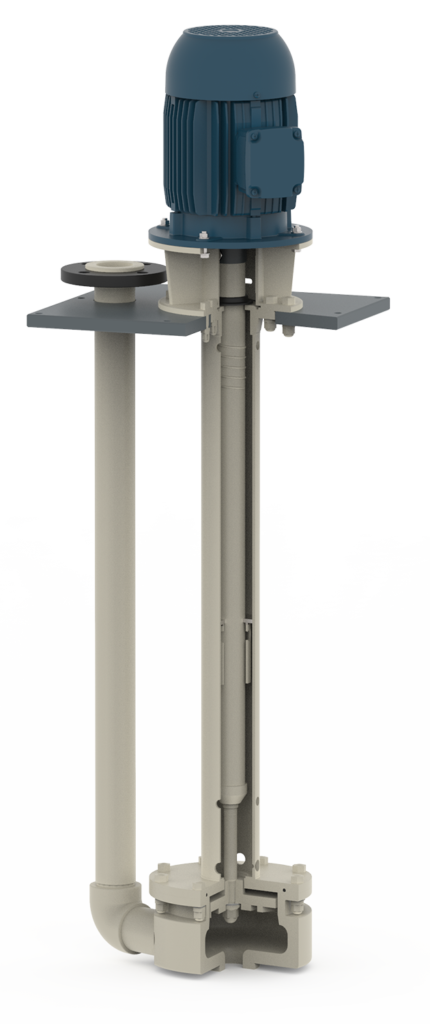

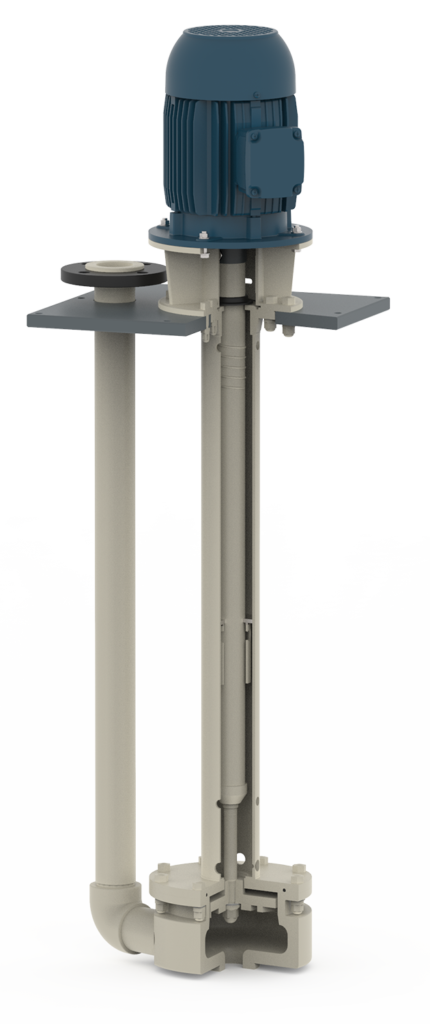

GA VERTICAL PUMPS

CORROSION-RESISTANT PLASTIC PUMPS. NON-CLOGGING IMPELLERS, IDEAL FOR PUMPING CHARGED AGGRESSIVE LIQUIDS OR EVEN VERY DIRTY INDUSTRIAL FLUIDS (COARSE SOLIDS, FIBRES, FILAMENTS, ETC.).

- Corrosion-resistant chemical pumps.

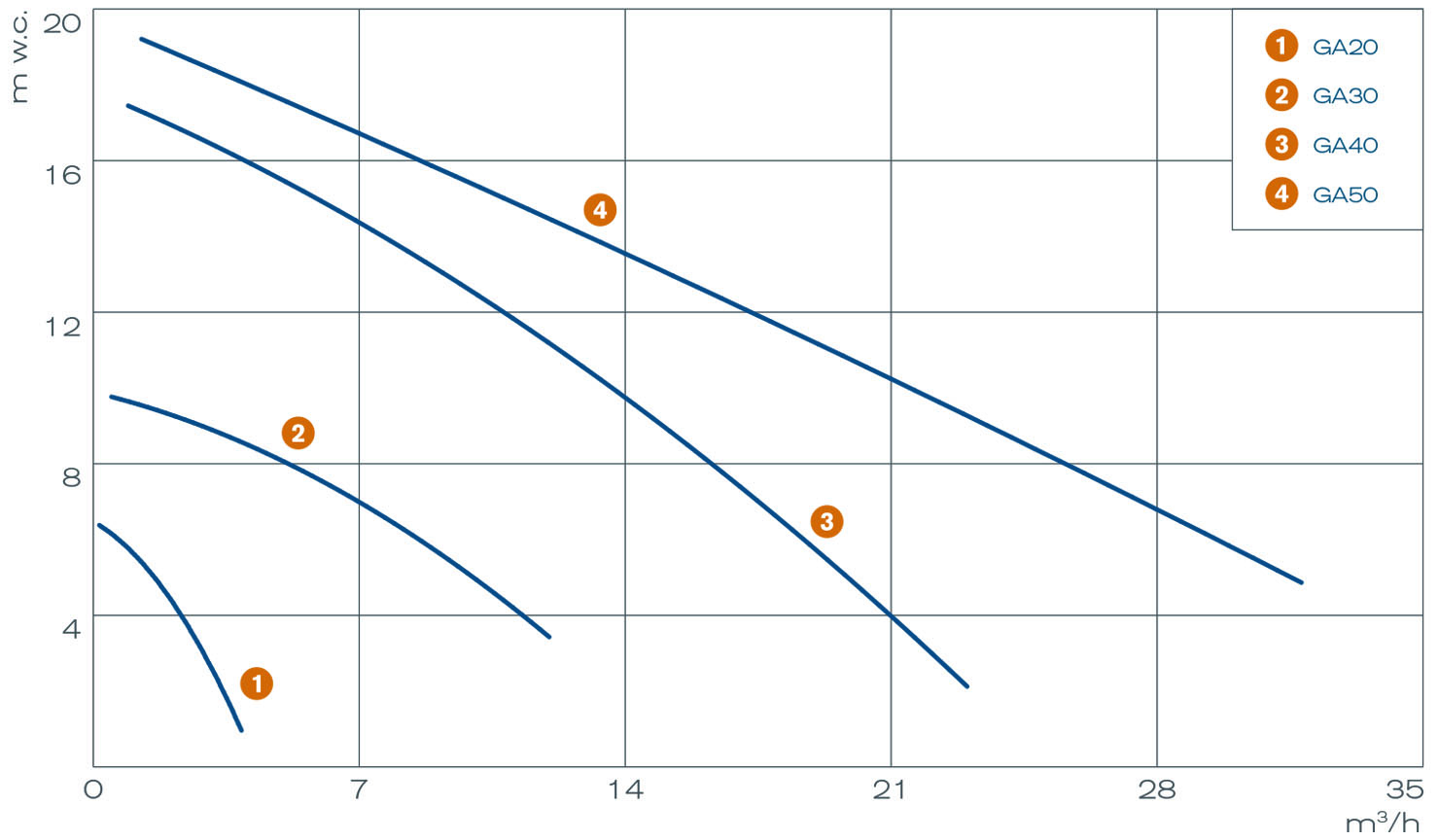

- Maximum flow rate: 32 m³/h.

- Maximum head: 20 m w.c.

- Plastic construction materials: PP, PVC, PVDF.

- With no metal parts in contact with chemical liquids.

- Fixed lengths (cantilever version): 400, 550, 700 and 900 mm.

- Custom-made lengths (version with bushings) up to 3000 mm.

- One-piece shaft with no intermediate bearings.

- Extensive internal clearance and recessed non-clogging impeller.

TECHNICAL INFORMATION

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

STRENGTHS

LESS METAL, LESS CORROSION

BS vertical pumps are made of corrosion-resistant thermoplastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The anti-acid performance of our pumps also comprises all nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coatings (PP, PVC, PVDF). Savino Barbera design eliminates the contact of metal with aggressive liquids.

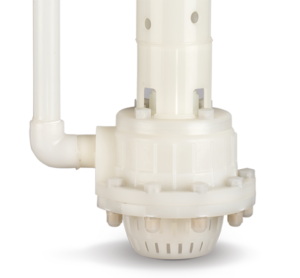

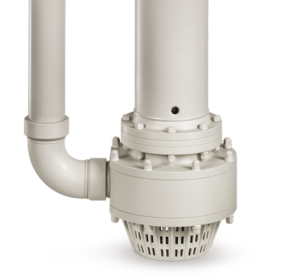

WITH AND WITHOUT BUSHINGS

Version with sliding bushings: pump-shaft equipped with bushings with no need for external lubrication. Version without bushings (cantilever): completely cantilevered pump-shaft, suitable for charged liquids or cases in which there is a very high risk of running dry.

MODULAR DESIGN

Version with bushings: custom-made lengths up to 3000 mm. Version without bushings (cantilever): Four fixed lengths (400, 550, 700, 900 mm). Connections: thread, hose adapter or flange.

DRY-RUNNING

GA pumps, in the version without end bushings, have the ability to run dry without problems, eliminating a classic limit of all plastic pumps. The absence of bushings makes it suitable for use even in the absence of liquid.

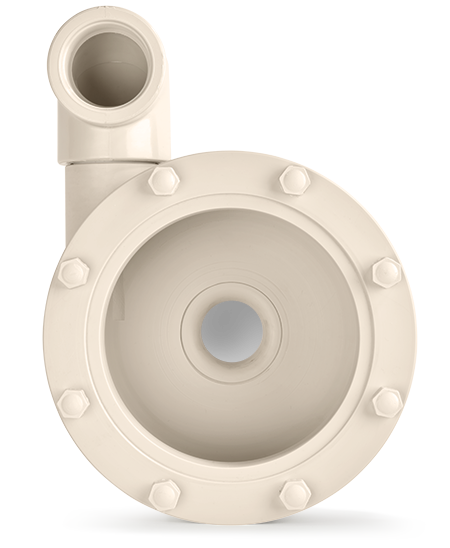

COARSE SOLIDS AND FILAMENTS

Extensive internal clearance and non-clogging impeller: features that facilitate the pumping of aggressive liquids containing foreign bodies, fibres or other impurities found in many industrial fluids.

LESS METAL, LESS CORROSION

BS vertical pumps are made of corrosion-resistant thermoplastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The anti-acid performance of our pumps also comprises all nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coatings (PP, PVC, PVDF). Savino Barbera design eliminates the contact of metal with aggressive liquids.

WITH AND WITHOUT BUSHINGS

Version with sliding bushings: pump-shaft equipped with bushings with no need for external lubrication. Version without bushings (cantilever): completely cantilevered pump-shaft, suitable for charged liquids or cases in which there is a very high risk of running dry.

MODULAR DESIGN

Version with bushings: custom-made lengths up to 3000 mm. Version without bushings (cantilever): Four fixed lengths (400, 550, 700, 900 mm). Connections: thread, hose adapter or flange.

DRY-RUNNING

GA pumps, in the version without end bushings, have the ability to run dry without problems, eliminating a classic limit of all plastic pumps. The absence of bushings makes it suitable for use even in the absence of liquid.

COARSE SOLIDS AND FILAMENTS

Extensive internal clearance and non-clogging impeller: features that facilitate the pumping of aggressive liquids containing foreign bodies, fibres or other impurities found in many industrial fluids.

DRY RUNNING!

The recessed non-clogging impeller and clearance inside the pump-casing make the GA a perfect chemical pump for extreme use, such as the handling of liquids containing suspended solids or (in the cantilever version only) when there is a risk of running dry. In this last case, GA Plastic pumps can be used to prevent the problems that occur when the liquid no longer reaches the pump for some reason.

THE DETAILS THAT MAKE THE DIFFERENCE

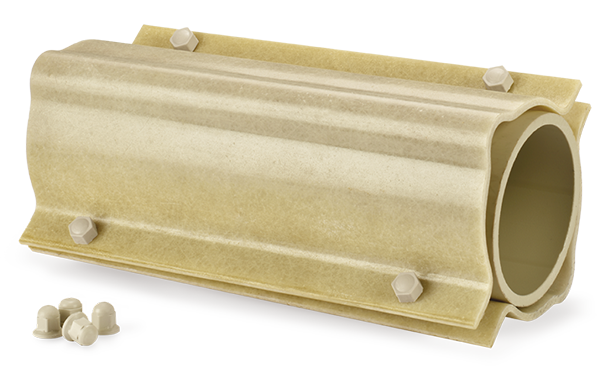

FRP REINFORCEMENT

From lengths of 2000 mm upwards, Savino Barbera vertical pumps have aluminium motor supports, oversized shafts and fibreglass outer structures. This is a construction solution that ensures additional resistance to vibrations while protecting the pump from other mechanical or thermal stress.

VERSION WITH BUSHINGS

In the supported shaft versions, the only guide element of GA pumps consists of a pair of bushings positioned at the end of the pump shaft. The bushings are available in materials suited to chemical liquids, fluids containing sludge or suspended solids: filled-PTFE, sintered ceramic or silicon carbide.

DELIVERY CONNECTIONS

The delivery connections of GA vertical pumps are available in three versions: threaded, hose adapter or flange. There are no extra charges for the optional features. In the event of particular requirements, special connections, lowered deliveries or flanges with ANSI 150 drilling can be mounted.

CORROSIVE LIQUIDS

- Nitric acid

- Muriatic acid

- Citric acid

- Brine

- Ammonia

- Caustic potash

- Chemical fertilisers

- Fertilisers

- Glycerine, glycol

- Fuels and biodiesel

- Solvents of various kinds

- Seawater

- Sulphuric acid

- Caustic soda

- Hydrochloric acid

- Sodium hydroxide

- Chromic acid

- Sodium hypochlorite

- Hydrofluoric acid

- Ferric chloride

- Aluminium polychloride

- Phosphoric acid

- Flocculants

- Polyelectrolytes

- Urea and AdBlue

- Sanitising gels

- Inks, dyes, paints

- Industrial oils

- Cosmetic liquids

- Industrial detergents

- Acetic acid

- Distilled water

- Demineralised water

- Hydrogen peroxide

- And your liquid, of course!

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST VERTICAL PUMPS SUPPLIES

GA50B CORROSION-PROOF PUMP

Non-clog centrifugal pump with recessed impeller for chemical liquids containing particles and solids.

NON-CLOG PLASTIC IMPELLER

Non-clog thermoplastic impeller specifically designed for corrosive slurries and solids-laden industrial fluids.

OPTION FOR DRY-RUNNING

Anti-corrosion pumps with solids handling capability. With the cantiliver shaft option, the pump can run dry.