SLOW-SPEED TOP-ENTRY INDUSTRIAL MIXERS

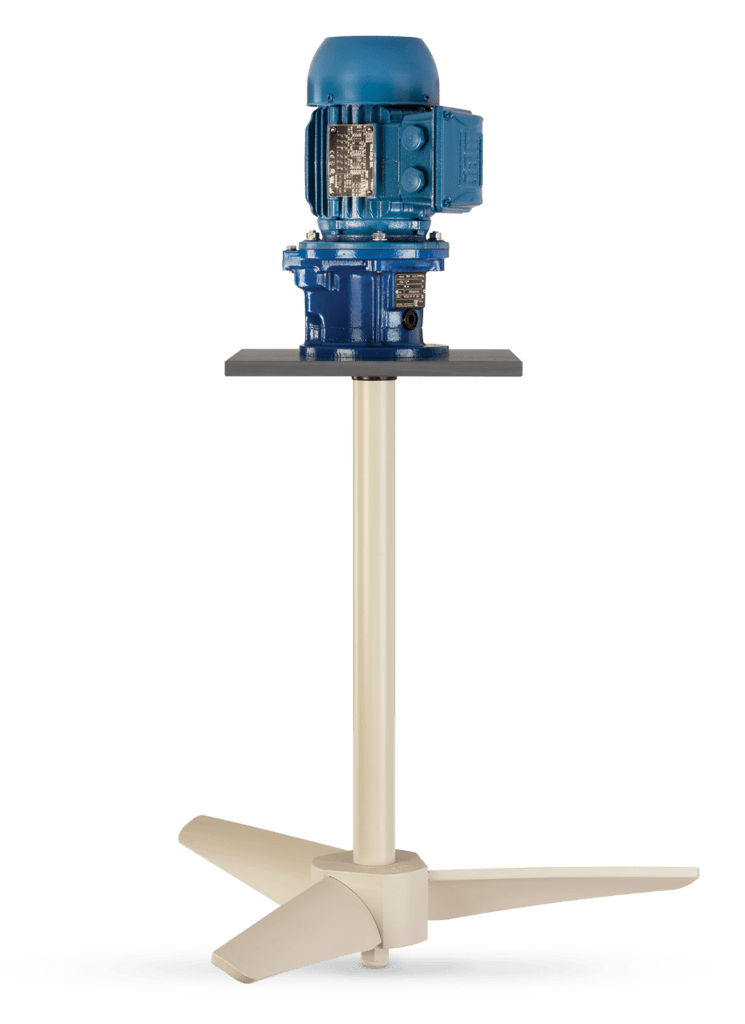

AR GEAR-DRIVE MIXERS

TOP ENTERING GEAR DRIVE MIXERS DESIGNED FOR USE WITH NON-PRESSURE TANKS. FIXED MOUNT MIXERS WITH CANTILEVERED SHAFT CONNECTED TO THE GEARMOTOR. CUSTOM-MADE LENGTHS TO SUIT THE DEPTH OF THE TANK.

- Chemically resistant industrial mixers.

- Slow speed mixing (with gear reducer).

- Axial or angular gearmotors.

- 4-6-8-pole electric motors.

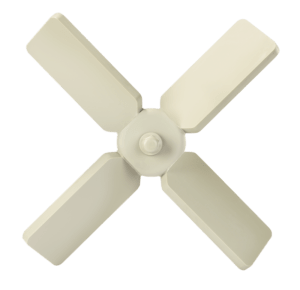

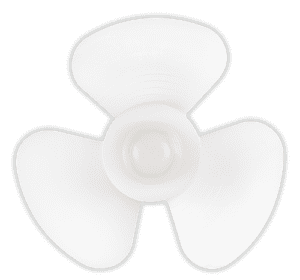

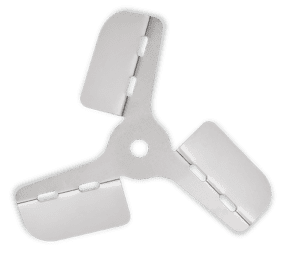

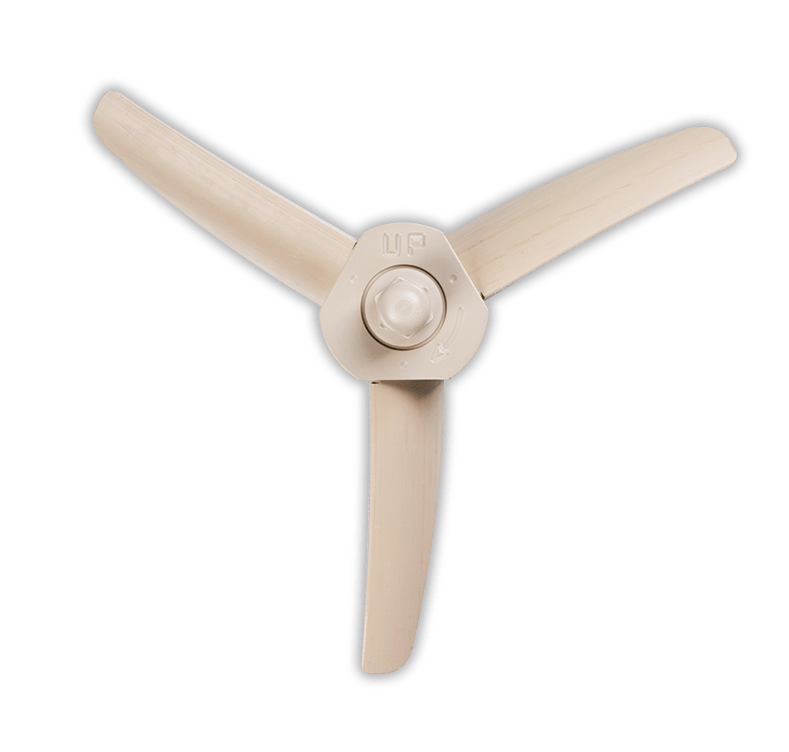

- High-efficiency three-blade or PBT four-blade impellers.

- Mixer materials: PP, PVC, PVDF, INOX.

- Impeller materials: PP, PVC, PVDF, INOX.

- Cantilevered shaft connected to the gearmotor.

- Custom-made lengths between 250 and 3500 mm.

Plastic version (PP – PVC – PVDF)

We also supply special custom-made mixers. Please contact our technical department for any special requirements.

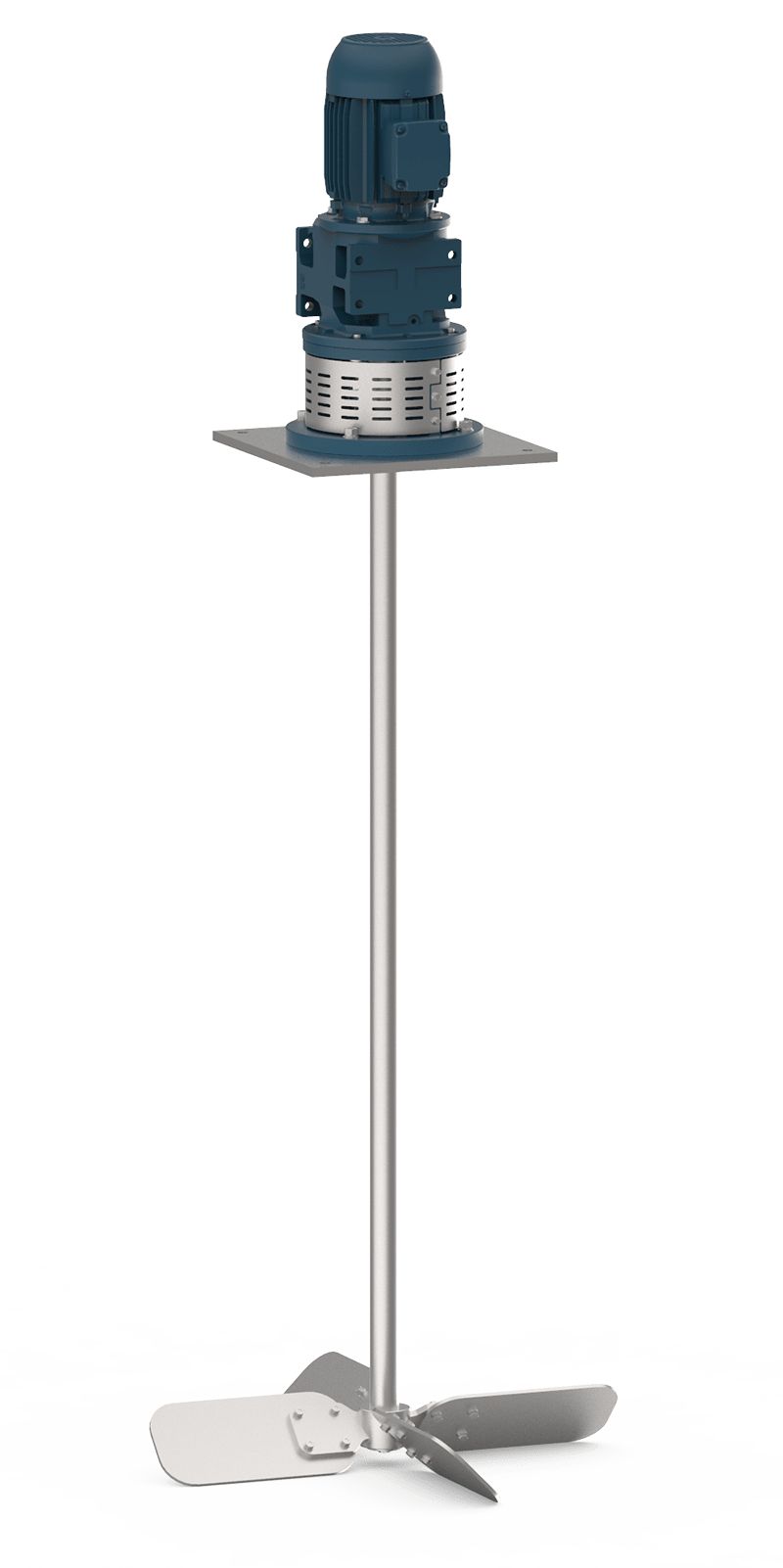

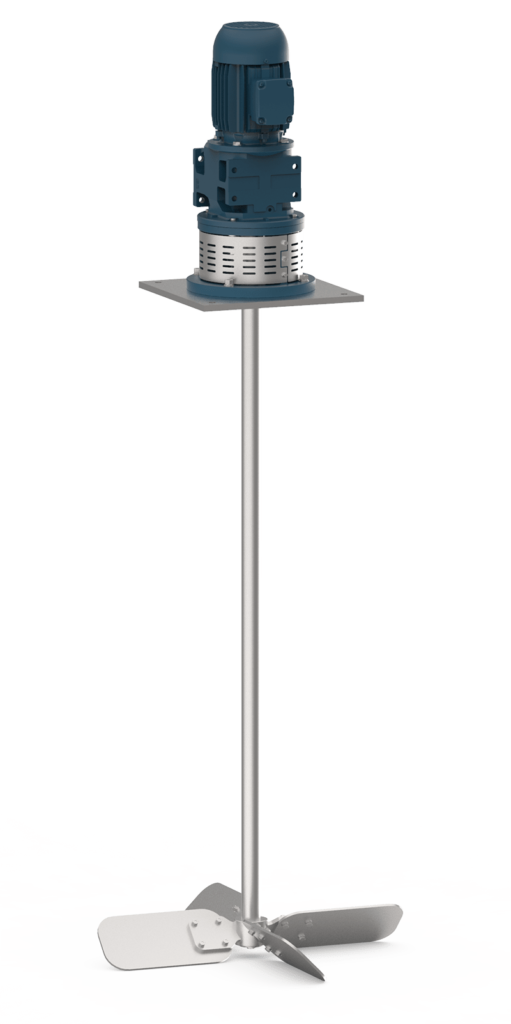

Metal version (AISI 304)

We also supply special custom-made mixers. Please contact our technical department for any special requirements.

download area

TECHNICAL CHARACTERISTICS

GEAR-DRIVE MIXERS

AR Series agitators are equipped with gear reducers (usually angular gearmotors with a monolithic cast iron casing lubricated-for-life). Coaxial gearmotors can also be fitted by request. Motor rotation speed: from 55 to 110 rpm. Possibility of use with inverter (60 Hz max).

HIGH-EFFICIENCY IMPELLERS

The profile of three-blade and four-blade impellers allows the use of low-power motors. The impellers are ideal for fluids that cannot be subjected to high turbulence or for mixtures where the pumping action must prevail over the shear. Dual impellers by request (in the metal version only).

SLOW-SPEED MIXERS

Top mounted geared mixers used typically when gentle mixing of the liquid is required, as in the case of water flocculation where the impeller blades must not affect the suspended flakes. Characterised by clockwise rotation when looking from the motor side: the flow generated is always downward.

MADE OF PLASTIC AND METAL

Flange mounted mixers with cantilever shaft connected to the gearmotor with a rigid coupling. Custom-made construction lengths from 250 to 3500 mm depending on the depth of the tank. Available in corrosion-resistant plastic materials and stainless steel.

TECHNICAL CHARACTERISTICS

GEAR-DRIVE MIXERS

AR series agitators are equipped with gear reducers (usually angular gearmotors with a monolithic cast iron casing lubricated-for-life). Coaxial gearmotors can also be fitted by request. Motor rotation speed: from 55 to 110 rpm. Possibility of use with inverter (60 Hz max).

HIGH-EFFICIENCY IMPELLERS

The profile of three-blade and four-blade impellers allows the use of low-power motors. The impellers are ideal for fluids that cannot be subjected to high turbulence or for mixtures where the pumping action must prevail over the shear. Dual impellers by request (In the metal version only).

SLOW-SPEED MIXERS

Top mounted geared mixers used typically when gentle mixing of the liquid is required, as in the case of water flocculation where the impeller blades must not affect the suspended flakes. Characterised by clockwise rotation when looking from the motor side: the flow generated is always downward.

MADE OF PLASTIC AND METAL

Flange mounted mixers with cantilever shaft connected to the gearmotor with a rigid coupling. Custom-made construction lengths from 250 to 3500 mm depending on the depth of the tank. Available in corrosion-resistant plastic materials and stainless steel.

EXAMPLES OF APPLICATIONS

- Acidification and neutralisation of water

- Fertigation systems

- Dissolution of salts in liquids

- Denitrification processes

- Preparation of polyelectrolyte solutions

- Chlorination systems

- Preparation of chemical reagents

EXAMPLE OF

CHEMICAL PRODUCTS

- Nitric acid

- Phosphoric acid

- Hydrochloric acid

- Chlorine and derivatives

- Sulphuric acid

- Nitrogen, phosphorus, potassium

- Nitrate, phosphate, sulphate

EXAMPLES OF APPLICATIONS

- Acidification and neutralisation of water

- Fertigation systems

- Dissolution of salts in liquids

- Denitrification processes

- Preparation of polyelectrolyte solutions

- Chlorination systems

- Preparation of chemical reagents

EXAMPLE OF

CHEMICAL PRODUCTS

- Nitric acid

- Phosphoric acid

- Hydrochloric acid

- Chlorine and derivatives

- Sulphuric acid

- Nitrogen, phosphorus, potassium

- Nitrate, phosphate, sulphate

CONSTRUCTION MATERIALS

PP

The most widely used

anti-acid plastic polymer for use in corrosive environments. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, up to a temperature of 80°C.

PVC

Plastic material with excellent resistance to acids, bases, saline solutions and organic compounds. PVC is generally used when treating sodium hypochlorite (NaClO).

At low temperatures it becomes fragile. The operating temperature is between 40 and 60°C.

PVDF

Thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but

is ideal for highly concentrated acids.It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

AISI 304

AR mixers are also available in stainless steel. This version can be used to mix industrial liquids that are not particularly aggressive, such as: fertilisers, manures, quenching treatments, wastewater, graphite suspensions, mineral oils. Maximum operating temperature: approx. 100°C

HOW TO CHOOSE A MIXER

In order to size a specific mixer and ensure effective mixing, it is necessary to evaluate several variables which often interact with each other: the type of liquid (or liquids) to be mixed, the volume to be handled, the purpose of the process, the geometry of the container, the position of the mixer. In this preliminary operation, the manufacturer’s experience is always a decisive added value, given the changing conditions that frequently affect industrial processes and liquids.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST INDUSTRIAL MIXERS SUPPLIES

GENTLE PRODUCT TREATMENT

Plastic mixers with angular gearmotor for a solution of water with sulfuric acid and calcium hydroxide.

MAINTAINING UNIFORM TEMPERATURE

AR30 stainless steel geared drive mixer to eliminating temperature stratification of an aqueous solution.

MIXER WITH 1370 RPM

AR30 slow rotation metal mixer (1370 rpm). Liquids: phenolic resin, ammoniun sulfate, silane, silicone.

SLOW SPEED TOP ENTRY MIXER

AR50 geared industrial mixer providing slow speed agitation for a graphited-base solution of bonderite.

LIME MILK PREPARATION UNIT

Top entering thermoplastic industrial mixers with 3000 mm shaft. Application: milk of lime preparation.

TOP ENTRY GEAR DRIVE MIXERS

AR100 vertical mixer with motor-gear (70 rpm). Length of 2160 mm. For chemical solution slow mixing.

SOLIDS SUSPENSION MIXER

Slow moving metal stirrer providing a gentle mixing pattern for water mixed with silicon carbide particles.

INDUSTRIAL GEARED MIXERS

Polypropylene AR100 geared mixers for a slow speed agitation of water, silicon carbide powder and glycol.

SLOW SPEED INDUSTRIAL MIXERS

Slow speed geared mixers for atmosferic vessels. Impeller and shaft in corrosion-resistant polypropylene.

COAGULATION PROCESS

AR100 plastic mixer with a worm drive gearbox to slow its rotational speed. Application: flocculant preparation.

FURTHER INDUSTRIAL MIXERS