CHEMICAL DESCALING PUMPS

SCALE REMOVAL SYSTEMS

Chemical descaling units consisting of pumps and corrosion-resistant tanks with filters on the return line. Savino Barbera descaling pumps are used for the chemical washing of limestone deposits, accumulations of matter and other impurities that form over time in various types of civil and industrial plants. Without needing to disassemble single pipes or entire systems and without causing production stoppages, PFTs easily remove scale that reduces the performance of hydraulic circuits, both in terms of heat exchange and flow rate. Also available in a version on wheels.

PFT31 DESCALING PUMP

Basic model, compact and light. Quick descaling of small systems. The PFT31 has a vertical PVC pump and a 30-litre tank. Maximum flow rate of 3 m3/h and maximum head of 20 m w.c. Empty weight: 14 kg. The PFT31 is suitable for services that are not prolonged in time.

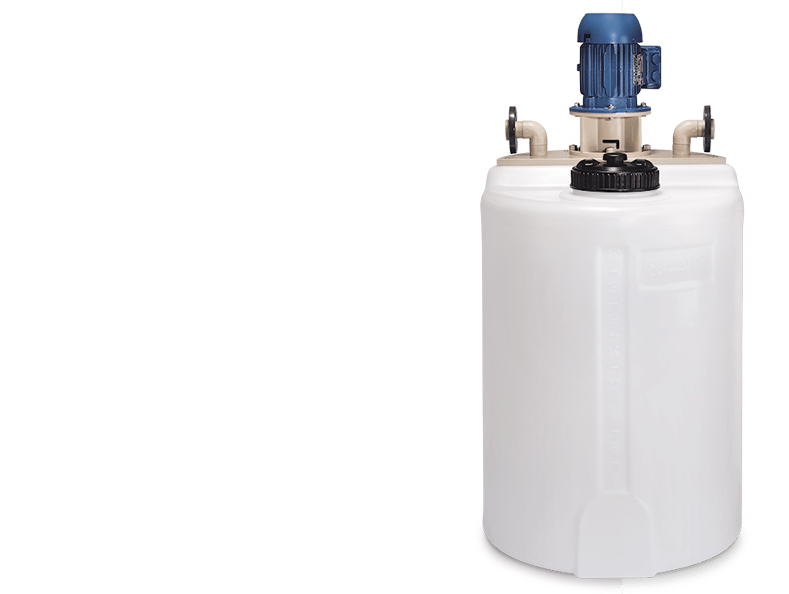

OTHER MODELS: PFT61-108-230-315

PFT scale removal systems are also available in four other sizes, depending on the chemical pumps and tanks used. The PFT61, PFT108, PFT230 and PFT351 models all have the same function: to remove impurities and residues from medium and large systems. Maximum flow rate: 40 m³/h. Maximum head 25 m w.c.

PFT31 DESCALING PUMP

Basic model, compact and light. Quick descaling of small systems. The PFT31 has a vertical PVC pump and a 30-litre tank. Maximum flow rate of 3 m3/h and maximum head of 20 m w.c. Empty weight: 14 kg. The PFT31 is suitable for services that are not prolonged in time.

OTHER MODELS: PFT61-108-230-315

PFT scale removal systems are also available in four other sizes, depending on the chemical pumps and tanks used. The PFT61, PFT108, PFT230 and PFT351 models all have the same function: to remove impurities and residues from medium and large systems. Maximum flow rate: 40 m³/h. Maximum head 25 m w.c.

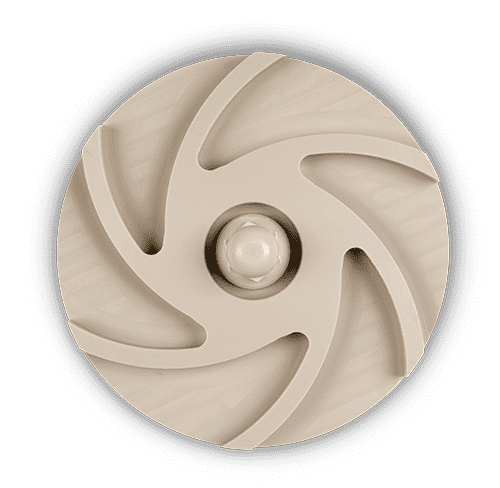

ACID-RESISTANT PUMPS

PFT scale removal systems are fitted with Savino Barbera vertical pumps with performances suited to specific descaling needs. The plastic chemical pumps in the tanks are standard AS series centrifugal pumps (AS20, AS30, AS40, AS50): plastic pumps without intermediate supports for chemical applications. Their thermoplastic materials (PP, PVC, PVDF) are selected carefully to suit the corrosive liquid to be pumped. These anti-acid pumps have no metal parts in direct contact with the fluids pumped, making them very resistant to chemical aggression.

THERMOPLASTIC MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of anti-acid centrifugal pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

PVC (POLYVINYL CHLORIDE)

Plastic material with an excellent resistance to acids, bases, saline solutions and organic compounds. PVC is generally used for pumping sodium hypochlorite (NaClO). At low temperatures it becomes fragile. The operating temperature is between 40 and 60°C.

PVDF (POLYVINYLDENFLUORIDE)

Fluorinated thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

HOW, WHAT, WHERE

PFT chemical descaling units represent the ideal choice for the flushing of chemical cleaning products: having no metal parts in direct contact with liquids, they are free from corrosion. The aggressive liquids that can be pumped are: liquid descaling agents, surfactants, neutralising agents, alkaline mixtures, colour change indicators, acid detergents, chemical additives, degreasers, corrosion inhibitors, passivating acids, dispersing agents, descalers… PFTs can be used for the chemical descaling of: cooling towers, boilers, condensers, heating systems, radiators, moulding equipment, circuits, coils… The impurities that are chemically washed: algae, bacteria, corrosion residues, sludge build-up, scale, salts, clumps of rust, limestone deposits…

HOW, WHAT, WHERE

PFT chemical descaling units represent the ideal choice for the flushing of chemical cleaning products: having no metal parts in direct contact with liquids, they are free from corrosion. The aggressive liquids that can be pumped are: liquid descaling agents, surfactants, neutralising agents, alkaline mixtures, colour change indicators, acid detergents, chemical additives, degreasers, corrosion inhibitors, passivating acids, dispersing agents, descalers… PFTs can be used for the chemical descaling of: cooling towers, boilers, condensers, heating systems, radiators, moulding equipment, circuits, coils… The impurities that are chemically washed: algae, bacteria, corrosion residues, sludge build-up, scale, salts, clumps of rust, limestone deposits…

DESCALING WITHOUT DISMANTLING

OPTIONAL ACCESSORIES

- Level controls and hoses.

- Drainage valves and electrical control panels.

- Metal supports with wheels or feet.

- Threaded connections, flanged connections or hose adaptor.

- Double containment tanks.