HORIZONTAL CHEMICAL PUMPS

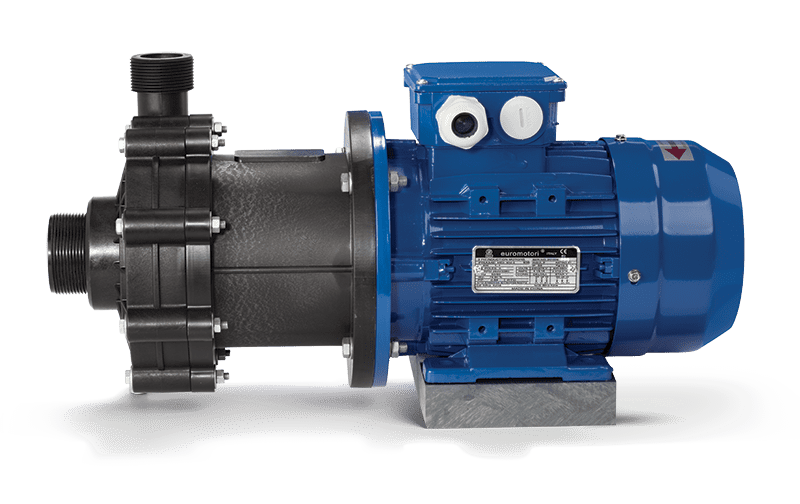

MAGNETICALLY DRIVEN PUMPS

Horizontal centrifugal magnetic drive pumps with leakproof design: their magnetic coupling and the absence of dynamic seals reduce the risk of leaking. Suitable for pumping very aggressive acids and hazardous toxic substances. Recommended exclusively for use with clean liquids with no suspended solids. Also available with explosion-proof or Atex-approved motors. Construction materials: anti-acid plastic (PP and PVDF) and metal (AISI 316, HASTELLOY).

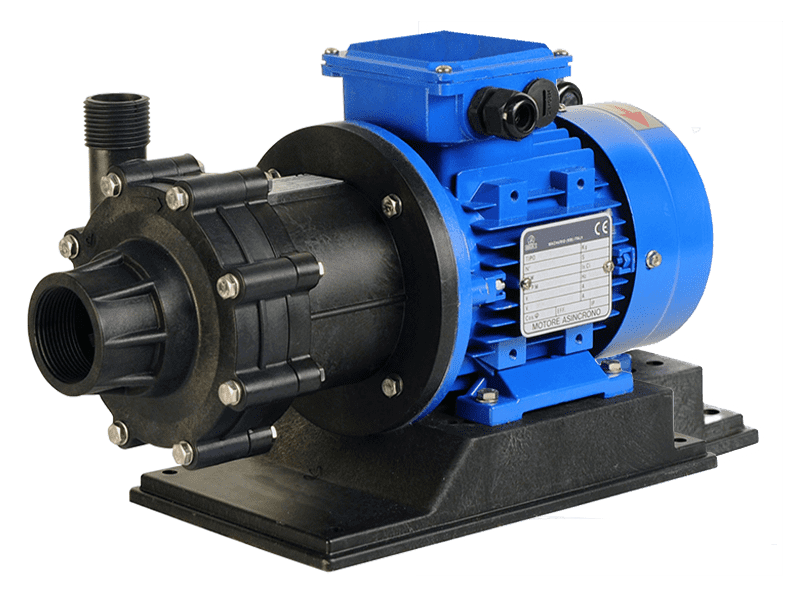

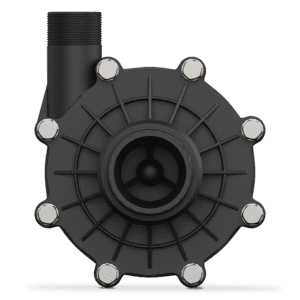

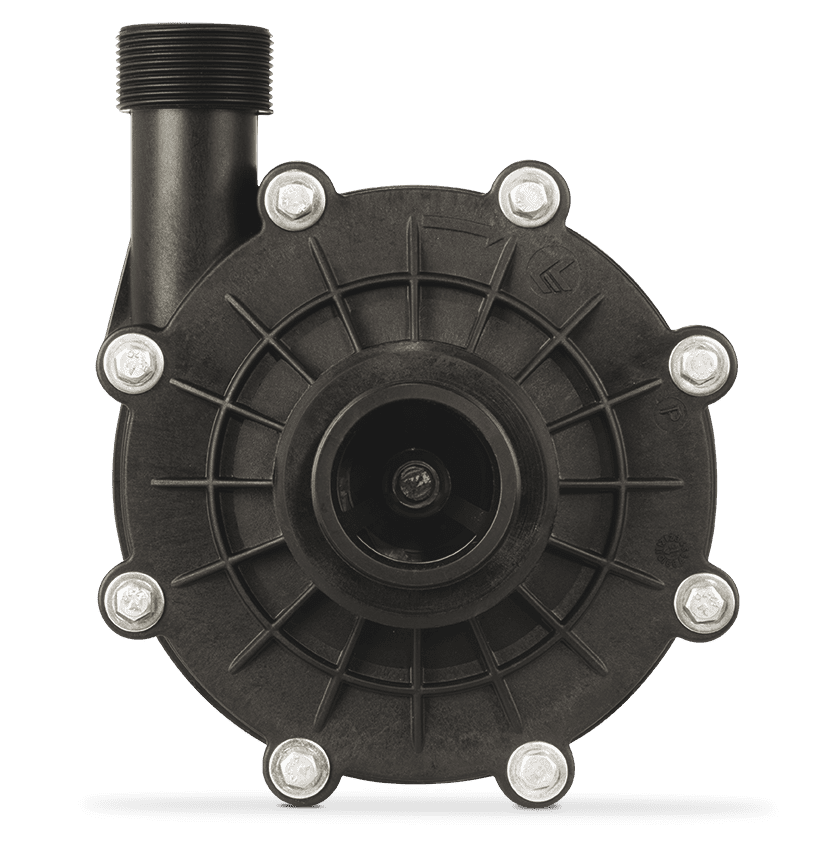

BM & MD PUMPS: PLASTIC SERIES

Corrosion-resistant plastic magnetic pumps (PP and PVDF). Suitable for pumping concentrated corrosive acids. No metal parts in direct contact with the liquid. Maximum flow rate: 135 m³/h. Maximum head: 48 m w.c.

BM & MD PUMPS: PLASTIC SERIES

Corrosion-resistant plastic magnetic pumps (PP and PVDF). Suitable for pumping concentrated corrosive acids. No metal parts in direct contact with the liquid. Maximum flow rate: 135 m³/h. Maximum head: 48 m w.c.

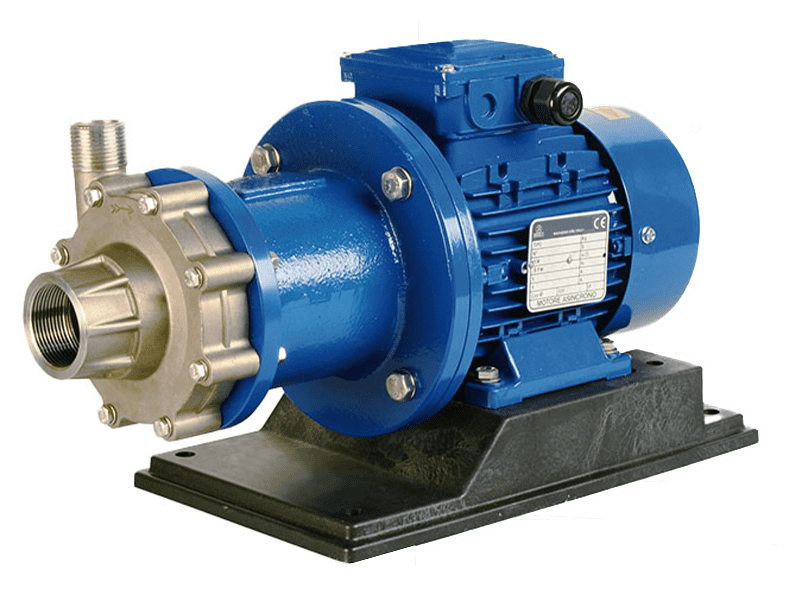

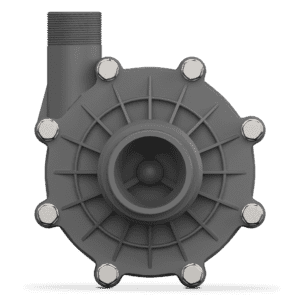

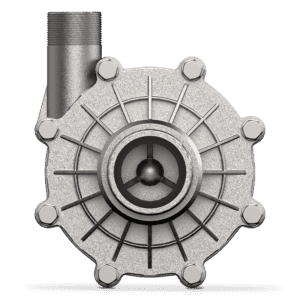

BM SERIES PUMPS: METAL SERIES

Metal magnetic coupling pumps. For hazardous chemical liquids such as solvents and hydrocarbons. The Metal Series is also suitable for hot liquids (160°C max). Maximum flow rate: 32 m³/h. Maximum head: 24 m w.c.

BM SERIES PUMPS: METAL SERIES

Metal magnetic coupling pumps. For hazardous chemical liquids such as solvents and hydrocarbons. The Metal Series is also suitable for hot liquids (160°C max). Maximum flow rate: 32 m³/h. Maximum head: 24 m w.c.

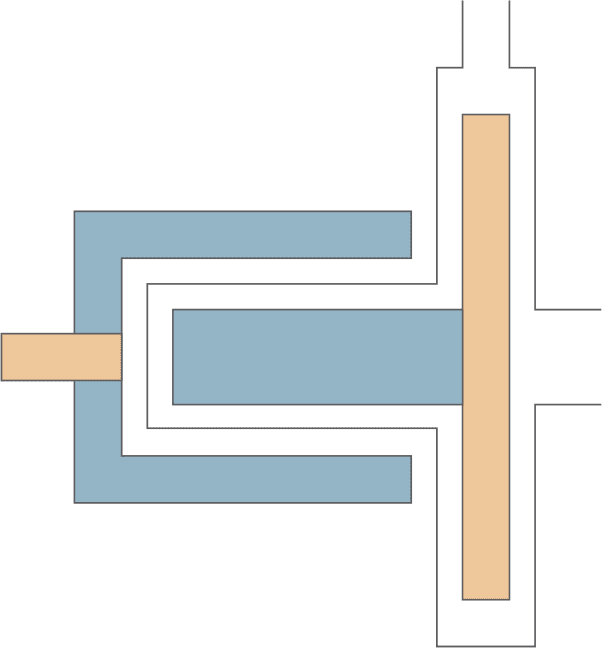

MAGNETIC COUPLING

Savino Barbera magnetic pumps are fitted with closed impellers and permanent magnets made of Neodymium Iron Boron (NeFeB) and Samarium Cobalt (SmCo). The magnetic coupling is protected from chemical aggression by a corrosion-resistant coating (PP and PVDF), but magnetic drive pumps are still sensitive to harsh operating conditions. The thin plastic coating of the magnets and the closed channels of the impeller do not withstand liquids with very abrasive solids and metallic particles.

THERMOPLASTIC MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of anti-acid centrifugal pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C.

PVDF (POLYVINYLDENFLUORIDE)

Fluorinated thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

METAL (AISI316, HASTELLOY)

BM magnetic pumps are also available in stainless steel or hastelloy. With these metallurgies, they can pump difficult liquids such as: hydrocarbons, solvents, coolants, some oils, some flammable liquids. Operating temperature: 160°C max (version with graphite bushings).

These pumps are driven by a pair of opposed magnets: the magnetic field developed between the inductor magnet (connected to the motor) and the induced magnet (attached to the impeller) conveys the torque necessary to move the fluid. There are two separate drive shafts: the motor shaft does not extend inside the pump body so there is no need for any rotating shaft seal (the magnetic coupling provides the pump-motor connection). Consequently, the permanent magnets do not come into contact with each other: a static containment shell (made of corrosion-proof plastic) isolates the liquid, eliminating the possibility of hazardous leaks. This is the reason why magnetic pumps are so popular: as they have no mechanical seal they are considered to be leakproof pumps. Always remember that magnetic drive pumps are strongly conditioned by certain critical applications, such as dirty liquids (metal powders are not compatible with magnets while suspended solids or sludge easily clog the closed impeller) or very viscous liquids (which require very powerful motors).

These pumps are driven by a pair of opposed magnets: the magnetic field developed between the inductor magnet (connected to the motor) and the induced magnet (attached to the impeller) conveys the torque necessary to move the fluid. There are two separate drive shafts: the motor shaft does not extend inside the pump body so there is no need for any rotating shaft seal (the magnetic coupling provides the pump-motor connection). Consequently, the permanent magnets do not come into contact with each other: a static containment shell (made of corrosion-proof plastic) isolates the liquid, eliminating the possibility of hazardous leaks. This is the reason why magnetic pumps are so popular: as they have no mechanical seal they are considered to be leakproof pumps. Always remember that magnetic drive pumps are strongly conditioned by certain critical applications, such as dirty liquids (metal powders are not compatible with magnets while suspended solids or sludge easily clog the closed impeller) or very viscous liquids (which require very powerful motors).

SOME PUMPED LIQUIDS

- Sulphuric acid

- Hydrochloric acid

- Chromic acid

- Hydrofluoric acid

- Acetic acid

- Phosphoric acid

- Caustic soda

- Nitric acid

- Formic acid

- Sodium chloride

- Photographic liquids

- Urea and AdBlue

- Hydrogen peroxide

- Demineralised water

- Ferric chloride

- Bromides

- Aluminium polychloride

- Galvanic baths

- Ammonia

- Brine

- And your liquid of course!

OTHER STRENGTHS

- Compact design, ideal for reduced industrial spaces.

- Plastic bases suitable for B3/B5 motors (by request).

- Leakproof design: no mechanical seals.

- Threaded (standard version) or flanged connections (by request).