CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

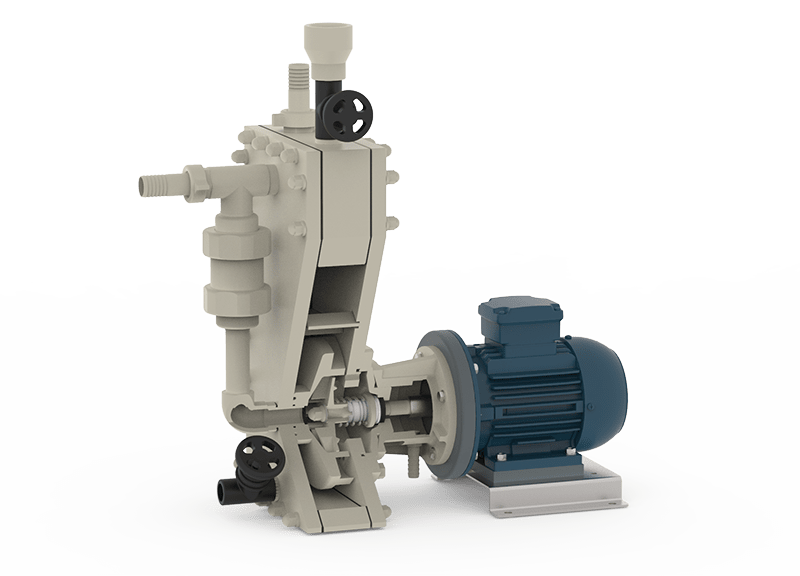

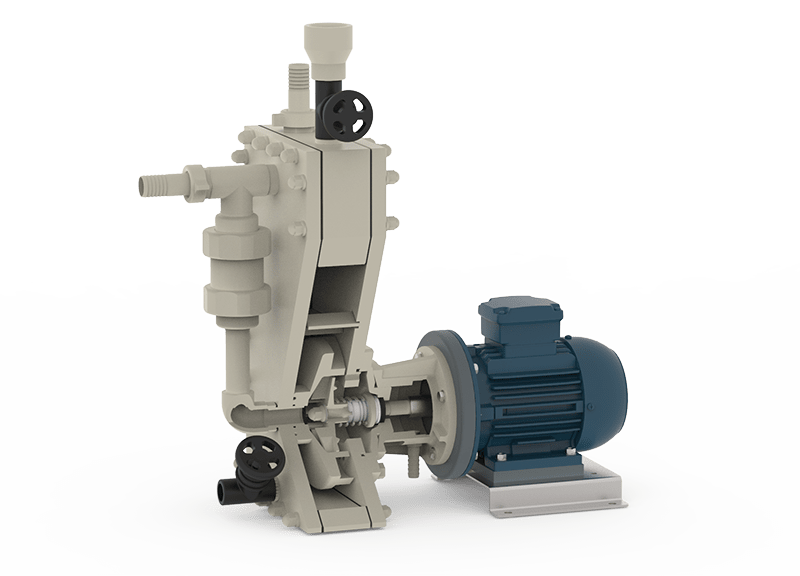

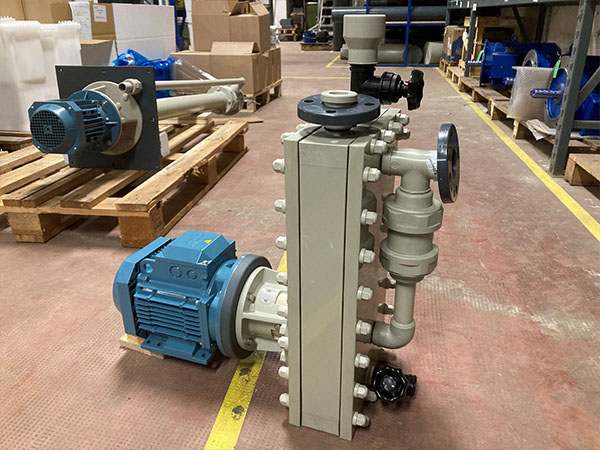

PA SELF-PRIMING PUMPS

SELF-PRIMING PUMPS WITH MECHANICAL SEAL. FOR PUMPING AGGRESSIVE LIQUIDS, INDUSTRIAL FLUIDS, ACID SOLUTIONS AND CHEMICALS.

- Corrosion-resistant chemical pumps.

- For installation above the level of the liquid.

- Maximum suction lift: 4 m.

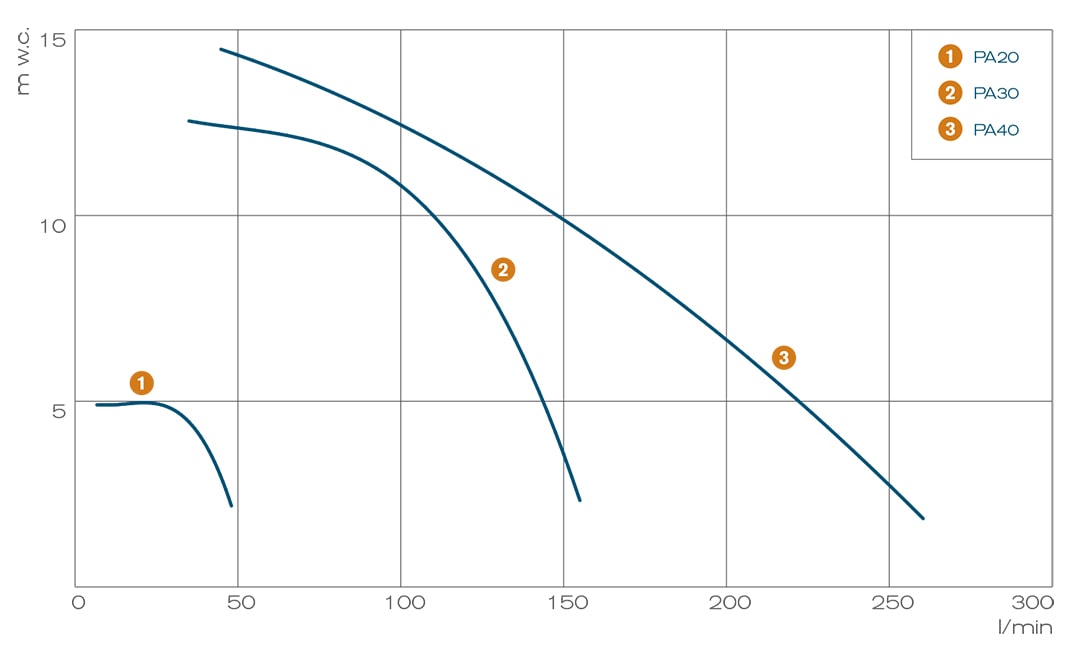

- Maximum flow rate: 280 l/min.

- Maximum head: 15 m w.c.

- Plastic construction materials: PP, PVC, PVDF.

- With no metal parts in contact with aggressive liquids.

- Mechanically sealed for chemical applications

TECHNICAL INFORMATION

Standard curves: 50 Hz (60 Hz curves available on request). The curves refer to tests with cold, clean water and a density of 1000 kg/m3 (ISO9906). Hydraulic performance may change in relation to changes in the characteristics of the liquid to be pumped. Particular attention should be paid to the vapour pressure, which could prevent the priming of the pump.

.

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

STRENGTHS

THREE SIZES

Made in three sizes, PA self-priming pumps satisfy various requirements: emptying underground tanks, occasional emergency pumping, draining wells or general maintenance operations.

PRIMING CHAMBER

PA pumps have self-priming capabilities of up to 4 metres. The only operation necessary is the filling of their priming chamber the first time they are operated. Self-priming pumps need fluid in the casing to get started.

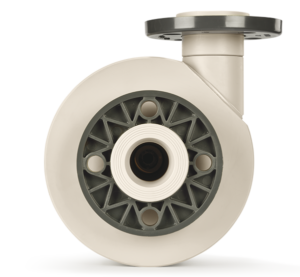

MECHANICAL SEAL

The anti-acid performance of our chemical pumps also comprises the mechanical seal, which is completely insensitive to corrosion. Consisting of three elements, it requires no adjustment or regulation with screws.

LESS METAL, LESS CORROSION

PA self-priming pumps are made of corrosion-resistant plastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and are built with maintenance in mind, using simplified components which can always be easily removed.

STRENGTHS

THREE SIZES

Made in three sizes, PA self-priming pumps satisfy various requirements: emptying underground tanks, occasional emergency pumping, draining wells or general maintenance operations.

PRIMING CHAMBER

PA pumps have self-priming capabilities of up to 4 metres. The only operation necessary is the filling of their priming chamber the first time they are operated. Self-priming pumps need fluid in the casing to get started.

MECHANICAL SEAL

The anti-acid performance of our chemical pumps also comprises the mechanical seal, which is completely insensitive to corrosion. Consisting of three elements, it requires no adjustment or regulation with screws.

LESS METAL, LESS CORROSION

PA self-priming pumps are made of corrosion-resistant plastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and are built with maintenance in mind, using simplified components which can always be easily removed.

SUCTION LIFT INSTALLATIONS

Pumps with a suction lift, to be chosen when it is not possible to use conventional horizontal pumps installed below the surface of the liquid (under-flooded installation) or vertical pumps with immersed column. Priming (with the casing initially filled) is automatic and without the need for a foot valve. Self-priming pumps cannot be used with dense, viscous or hot liquids with low vapour pressure (such as hydrochloric acid).

OPTIONS THAT MAKE A DIFFERENCE

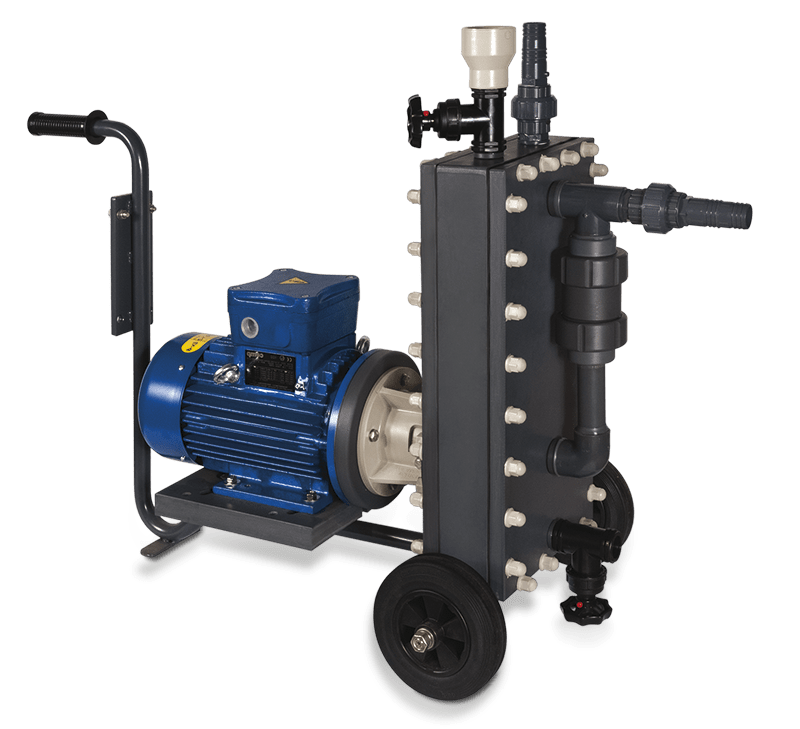

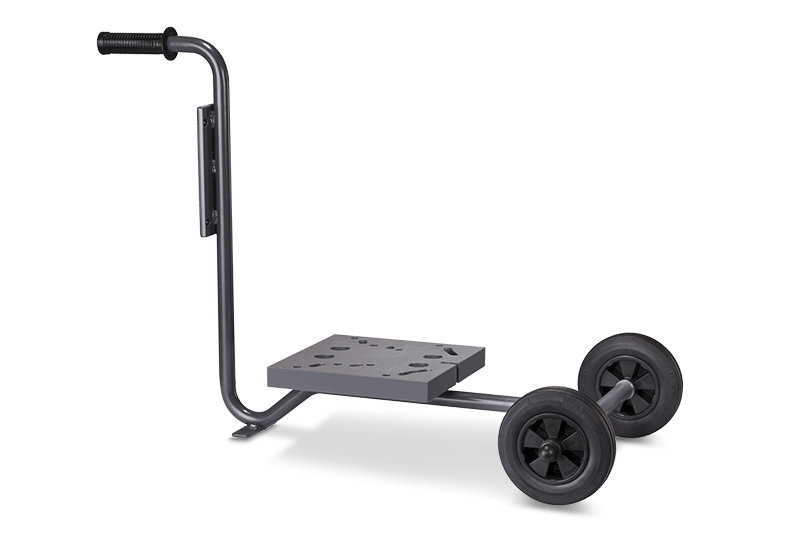

TROLLEY-MOUNTED PUMPS

Savino Barbera self-priming pumps can be mounted on trolleys. Transformed into practical portable units, they can be easily used for quick operations, emergency operations or occasional jobs (like filling and emptying tankers or emptying tanks in places far away from pipes or other fixed installations). The transport trolley is a powder-painted steel structure with a handle and with rubber and polypropylene wheels, to ensure silent movement and prevent damage to the floor.

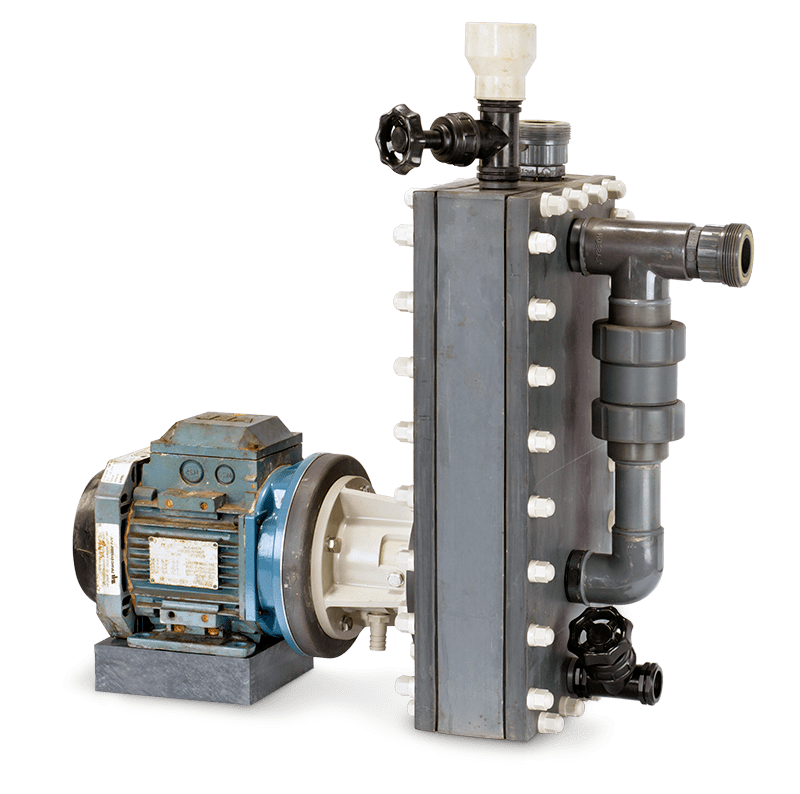

WITH PRIMING CHAMBER

Conventional horizontal close-coupled centrifugal pumps of the OMA series, when equipped with simple auxiliary single-chamber priming tanks (cylindrical), can recreate the operating conditions of PA self-priming pumps. With this special configuration (known as the SP Series), Savino Barbera chemical pumps can reach a maximum negative suction of 5 metres while guaranteeing higher flow rates than traditional PA self-priming pumps.

WARNINGS FOR USE

The use of self-priming pumps requires particular attention. By way of example, the delivery pipe must descend towards the pump, while the suction pipe must be as short as possible and have an inclination such as to avoid fluid stagnation or air bubbles. Moreover, their suction capacity is altered by unsupported piping, cut-off valves or non-return valves, tight curves and pipes with smaller diameters than the suction and delivery nozzles.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST SELPRIMING PUMPS SUPPLIES

MOBILE SELF-PRIMING PUMP

Self-priming plastic pump mounted on a mobile trolley for emptying a peracetic acid basin from the top.

SELF-PRIMING PLASTIC PUMP

PA30 self-priming chemical pump made from PP for pickling solution (hydrofluoric acid and sulfuric acid).

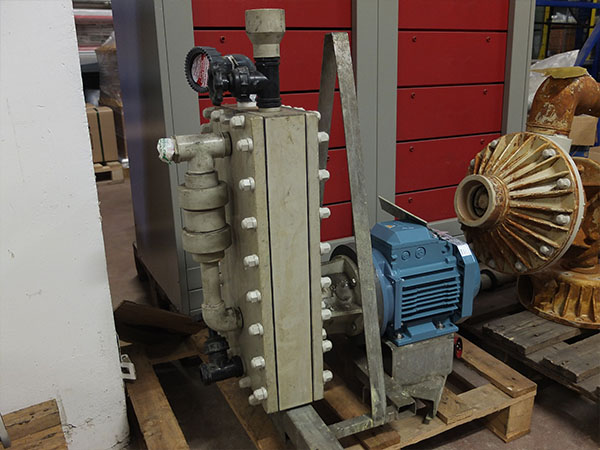

PA40 SELF-PRIMING PUMPS

Self-priming thermoplastic pumps for transferring dilute acid from underground sump pit of waste plant.

PUMPS FOR ALKALINE SOLUTION

Corrosion resistant self-priming pumps for aggressive alkaline solution contained in a chemical collection pit.

FOR CORROSIVE LIQUIDS

Acid-resistant pumps for trasferring hazardous wastewater contaminated by benzene, mercury and nickel.

PA20 NON METALLIC PUMPS

Full-plastic self-priming chemical processing pumps used to suck corrosive rinse water from a drain well.

FERROUS SULPHATE PA40 PUMP

Non corrosive self-priming pumps with dual mechanical seal for ferrous sulphate at a temperature of 30°C.

EMPTYING A COLLECTION PIT

Self-priming pump for emptying a collection sump filled of water mixed with sodium hydroxide (NaOH) at 60°C.

INSTEAD OF VERTICAL PUMP

Non metallic self-priming pump, instead of vertical pump, for handling chemicals collected in a sum pit.

FURTHER PLASTIC HORIZONTAL PUMPS