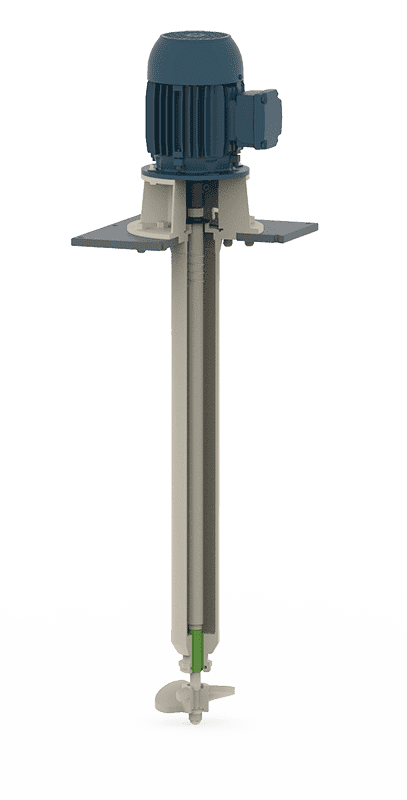

HIGH-SPEED TOP-ENTRY INDUSTRIAL MIXERS

AG DIRECT-DRIVE MIXERS

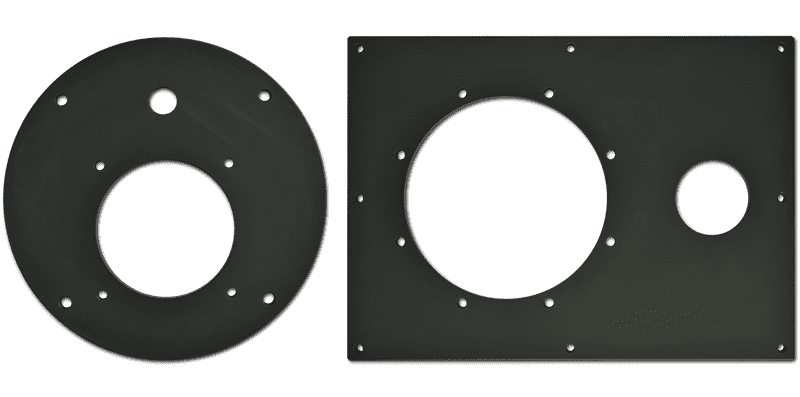

TOP-ENTRY FLANGE MOUNT MIXERS FOR OPEN TANKS AT ATMOSPHERIC PRESSURE. WITH SHAFT SUPPORTED BY BOTTOM BUSHINGS FOR ADDITIONAL MIXER STABILITY. CUSTOM-MADE LENGTHS TO SUIT THE DEPTH OF THE TANK.

- Chemically resistant industrial mixers.

- Fast rotation (with no gear reducer).

- 4-6-8-pole electric motors.

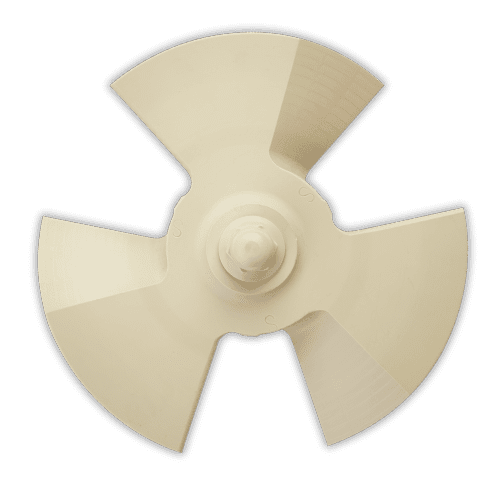

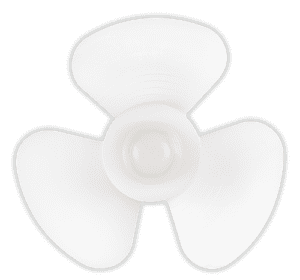

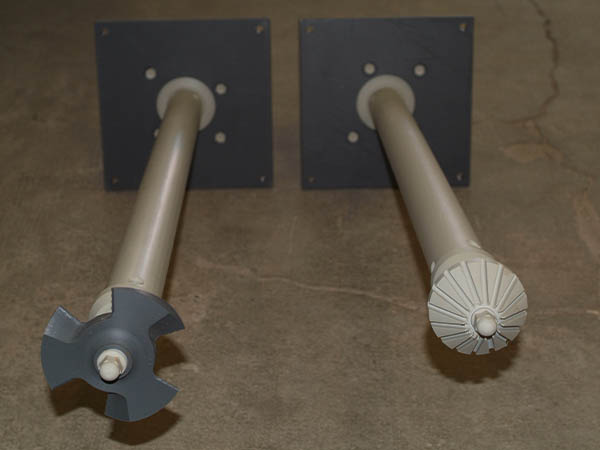

- Reversible marine propeller.

- Mixer materials: PP, PVC, PVDF.

- Impeller materials: PP, PVC, PVDF.

- Shaft with guide bushings flushed with liquid.

- Custom-made lengths between 350 and 3000 mm.