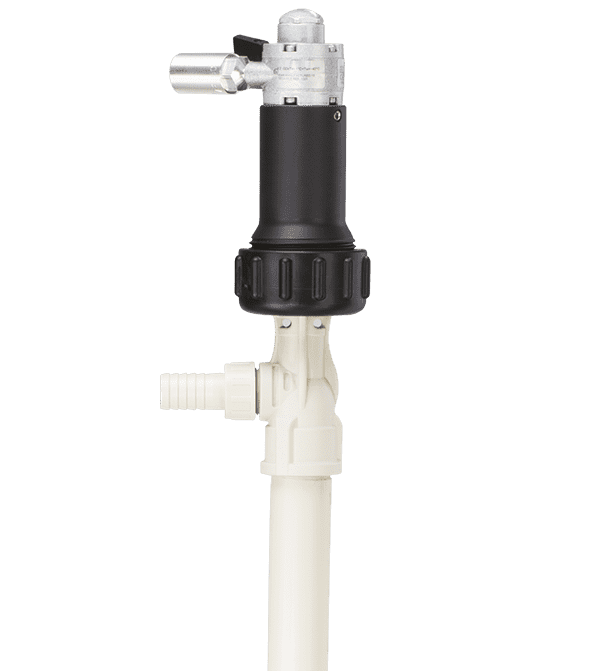

CHEMICAL DRUM & BARREL PUMPS

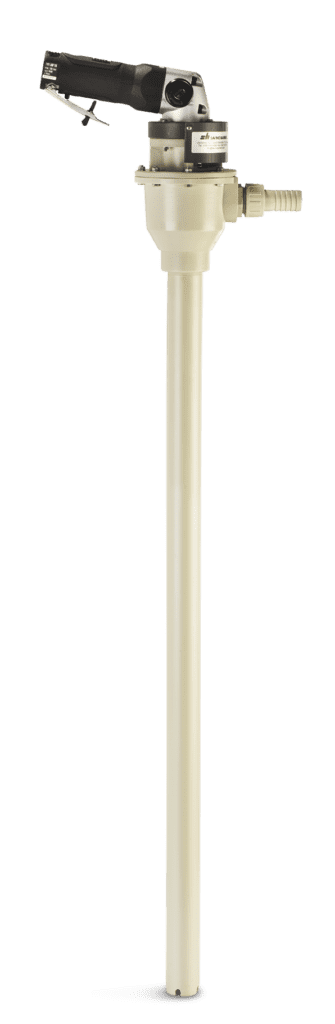

PLASTIC DRUM & BARREL PUMPS

CENTRIFUGAL CONTAINER PUMPS FOR EMPTYING CORROSIVE LIQUIDS FROM DRUMS, BARRELS AND TOTES. PORTABLE PUMPS SUITABLE FOR QUICK EMPTYING. MADE OF ACID-RESISTANT THERMOPLASTICS (PP, PVDF).

- For emptying drums, barrels, IBCs, bins and storages tanks.

- Maximum flow rate of 90 l/min and maximum head of 15 m w.c.

- Corrosion-resistant plastic materials: PP, PVDF.

- Suction pipe length: 700 mm, 900 mm, 1200 mm.

- Manageable pumps: weights from 3 to 8 kg.

- Motors: single-phase electric and air-operated pneumatic motors.

- Atex motors for explosive environments or flammable liquids.

- Suitable for non-abrasive corrosive chemicals.

- Pumping of liquids with a maximum viscosity of 900 cps.

- Ideal for the storage or distribution of chemicals.

- Suitable for intermittent, short-term service.

| Length | Q max l/m | H max m w.c. | Max Viscosity | ATEX rated | Material | |

|---|---|---|---|---|---|---|

| FUS PW mono | 900 | 50 | 8 | 50 cps | no | PP |

| FUS PW pneu | 900 | 50 | 10 | 50 cps | no | PP |

| TR PP mono 640W | 900 - 1200 | 90 | 11 | 600 cps | Only motor | PP |

| TR PP mono 800W | 900 - 1200 | 90 | 15 | 900 cps | no | PP |

| TR PP pneu 250W | 900 - 1200 | 80 | 9 | 600 cps | no | PP |

| TR PVDF mono 640W | 900 - 1200 | 90 | 11 | 600 cps | Only motor | PVDF |

| TR PVDF mono 800W | 900 - 1200 | 90 | 15 | 900 cps | no | PVDF |

| TR PVDF pneu 250W | 900 - 1200 | 80 | 9 | 600 cps | no | PVDF |

download area

KEY CHARACTERISTICS

HIGH-SPEED PUMPS

Plastic drum pumps can handle liquids with a maximum viscosity of 900 cps. They are centrifugal pumps with high-speed motors (10,000, 12,000, 18,000 rpm) and closed impellers (not suitable for dirty liquids).

IMMERSON TUBE: 42 MM Ø

The immersion tube of Savino Barbera transfer pumps has a 42 mm diameter, which makes it perfectly adaptable to the entrance of many small storage containers with narrow openings.

EASY TO HANDLE

Depending on the models, weights vary from 3 to 8 kg. The use of drum & barrel pumps always

requires the intervention of an operator and the maintenance of the tube in a vertical position inside the container, to stop them quickly when the fluid runs out.

FOR CORROSIVE LIQUIDS

After using them with your corrosive liquids, it is always advisable to pump clean water for a few minutes: some chemicals can, in fact, crystallise and form deposits or, over time, damage the construction materials of the pump.

KEY CHARACTERISTICS

HIGH-SPEED PUMPS

Plastic drum pumps can handle liquids with a maximum viscosity of 900 cps. They are centrifugal pumps with high-speed motors (10,000, 12,000, 18,000 rpm) and closed impellers (not suitable for dirty liquids).

IMMERSON TUBE: 42 MM Ø

The immersion tube of Savino Barbera transfer pumps has a 42 mm diameter, which makes it perfectly adaptable to the entrance of many small storage containers with narrow openings.

EASY TO HANDLE

Depending on the models, weights vary from 3 to 8 kg. The use of drum & barrel pumps always requires the intervention of an operator and the maintenance of the tube in a vertical position inside the container, to stop them quickly when the fluid runs out.

FOR CORROSIVE LIQUIDS

After using them with your corrosive liquids, it is always advisable to pump clean water for a few minutes: some chemicals can, in fact, crystallise and form deposits or, over time, damage the construction materials of the pump.

DRUMS, BARRELS, IBC, CONTAINERS

Drums, barrels, tanks, IBCs, bins, small industrial tanks, totes, and containment tanks. These are the various types of container where the use of drum pumps such as the FUS and TR models facilitates the rapid transfer of aggressive or hazardous liquids contained in them. Because of their practicality and ease of use, these transfer pumps are also an alternative to hand pumps or double diaphragm pumps, which are occasionally used to empty or fill industrial containers.

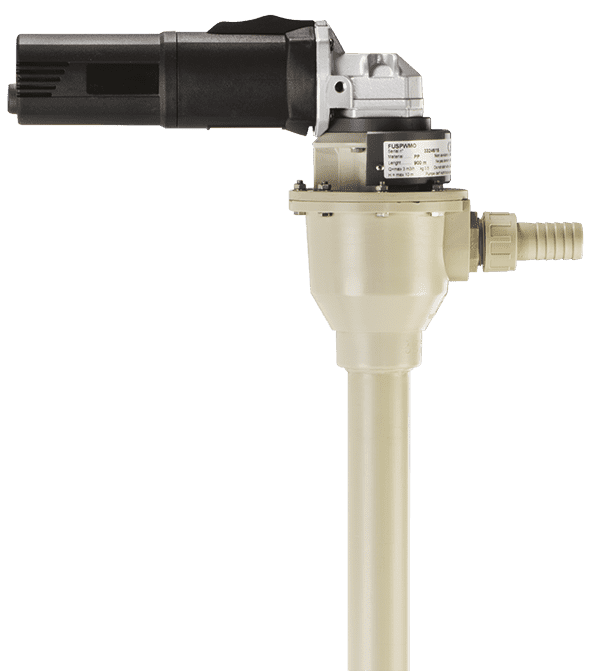

ELECTRIC DRIVE

RUPES BA 215 N single-phase motor, protection class II, Voltage 230 V, 50 Hz. Absorbed current: 4.1A. Absorbed power: 950 W. Equipped with 3 m power cable. With practical lateral auxiliary handle and switch with lock position for continuous operation. The electric motor is also available in a 48 V, 50 Hz, 800 W, 16° version (model BA 215 BT). The electric version is suitable for intermittent services not prolonged in time.

PNEUMATIC DRIVE

RUPES ANP 115 motor. Air consumption: the supply network must ensure the delivery of 600 l/min of filtered, dry and lubricated air with a pressure of 6 bar (operating pressure). The pneumatic motor is equipped with a safety switch to prevent accidental starts and has a practical handle on the side. Power supply connection: ¼”. The pneumatic version is suitable for continuous use.

ELECTRIC DRIVE

RUPES BA 215 N single-phase motor, protection class II, Voltage 230 V, 50 Hz. Absorbed current: 4.1A. Absorbed power: 950 W. Equipped with 3 m power cable. With practical lateral auxiliary handle and switch with lock position for continuous operation. The electric motor is also available in a 48 V, 50 Hz, 800 W, 16° version (model BA 215 BT). The electric version is suitable for intermittent services not prolonged in time.

PNEUMATIC DRIVE

RUPES ANP 115 motor. Air consumption: the supply network must ensure the delivery of 600 l/min of filtered, dry and lubricated air with a pressure of 6 bar (operating pressure). The pneumatic motor is equipped with a safety switch to prevent accidental starts and has a practical handle on the side. Power supply connection: ¼”. The pneumatic version is suitable for continuous use.

PLASTIC MATERIALS AND CORROSIVE LIQUIDS

Savino Barbera drum and barrel pumps are ideal for the fast dispensing and transfer of numerous chemicals used in the electroplating, tanning, petrochemical, water treatment and liquid logistics sectors and in many other manufacturing industries. Depending on the chemical resistance of the two construction materials available (PP and PVDF), the FUS and TR Series drum pumps are suitable for pumping industrial fluids and corrosive liquids with low viscosity and no suspended solids.

PP DRUM TRANSFER PUMPS

PP is widely used for the construction of anti-acid chemical pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of up to 80°C. Examples of liquids compatible with PP: mildly aggressive liquids, photographic developers, glycol, acids and bases with low concentrations.

PVDF DRUM TRANSFER PUMPS

Thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. Operating temperature: 100°C max. Highly concentrated acids and alkalis (such as hydrochloric acid, sulphuric acid, nitric acid, hydrofluoric acid). PVDF is also ideal for pumping hot corrosive products.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS