CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

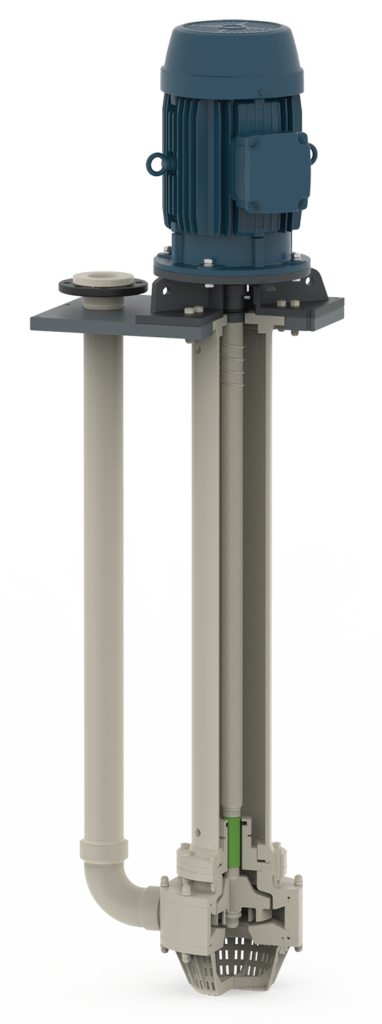

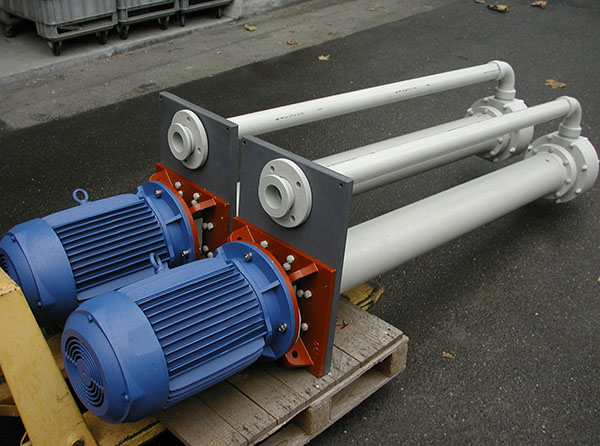

GP VERTICAL PUMPS

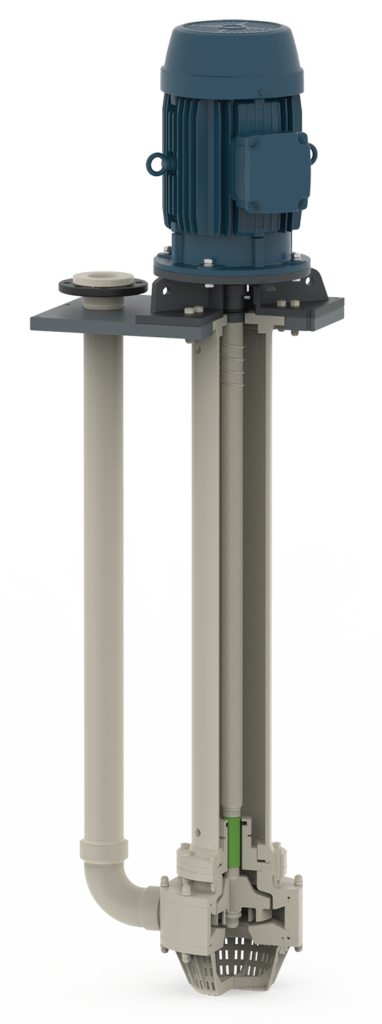

Corrosion-resistant plastic pumps. For pumping aggressive liquids, both acid and alkaline, clean industrial fluids and those with various kinds of impurities. Custom-made lengths to suit the depth of the tank. Ideal for continuous services and heavy-duty operations.

- Corrosion-resistant chemical pumps.

- Maximum flow rate: 200 m³/h.

- Maximum head: 42 m w.c.

- Thermoplastic construction material: PP.

- With no metal parts in contact with chemical liquids.

- Custom-made lengths between 750 and 3000 mm.

- One-piece shaft with no intermediate bearings.

- Wear bushings made of silicon carbide (SiC).

- Assembly in tank: no leaking.

TECHNICAL INFORMATION

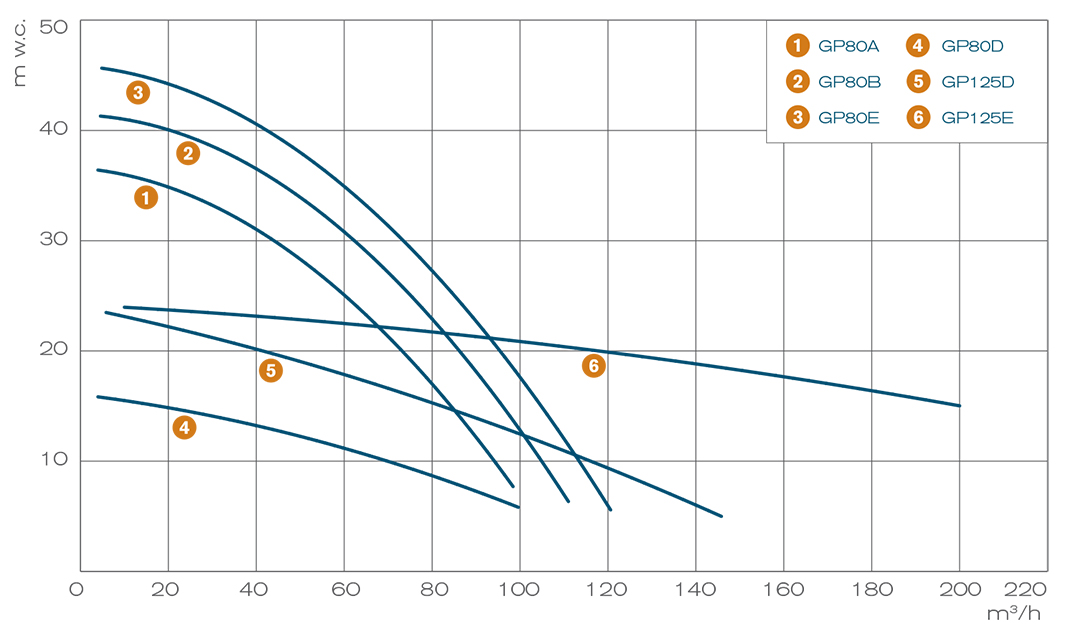

Standard curves: 50 Hz (60 Hz curves available on request). A-B series: open impeller. D series: 4-pole motor. E series: 2 or 4-pole motor. The curves refer to tests with cold, clean water and a density of 1000 kg/m3 (ISO9906). Hydraulic performance may change in relation to changes in the characteristics of the liquid to be pumped.

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

STRENGTHS

LESS METAL, LESS CORROSION

GP vertical pumps are made of corrosion-resistant thermoplastic material (polypropylene). All wetted parts are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The completely anti-acid performance of our pumps also comprises nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coating in PP. Savino Barbera design eliminates the direct contact of metal with aggressive liquids.

END BUSHINGS

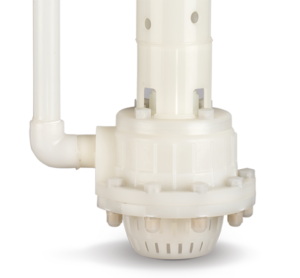

Sliding bushings with direct flushing, with no need for external lubrication. The standard version of pump bushings (external bushing) is made of SiC, a material with excellent resistance to wear and tear, and a low expansion and friction coefficient.

MODULAR DESIGN

Construction without predefined lengths, suited to any depth up to 3000 mm. Extra thick PVC support plates, also available in custom-made shapes and sizes. Delivery connection: DN80 or DN100 flange

CHEMICAL RESISTANCE

Machined from a solid block of polypropylene, GP centrifugal pump casings are structurally and chemically very robust. Thanks to their thick-walled plastic body, not only are they highly resistant to corrosion, they are also not affected by dirty liquids or high temperatures.

PLASTIC IMPELLERS

Plastic impellers with no metal inserts: resistant to attack from acid, even on the inside. Wide internal gaps facilitate the passage of coarse solids and the pumping of charged liquids.

STRENGTHS

LESS METAL, LESS CORROSION

GP vertical pumps are made of corrosion-resistant thermoplastic material (polypropylene). All wetted parts are insensitive to corrosion and consist of just a few elements, which can be easily removed over time.

ANTI-ACID PERFORMANCE

The completely anti-acid performance of our pumps also comprises nuts and bolts and pump shafts, metallic elements protected from corrosion by plastic coating in PP. Savino Barbera design eliminates the direct contact of metal with aggressive liquids.

END BUSHINGS

Sliding bushings with direct flushing, with no need for external lubrication. The standard version of pump bushings (external bushing) is made of SiC, a material with excellent resistance to wear and tear, and a low expansion and friction coefficient.

MODULAR DESIGN

Construction without predefined lengths, suited to any depth up to 3000 mm. Extra thick PVC support plates, also available in custom-made shapes and sizes. Delivery connection: DN80 or DN100 flange

CHEMICAL RESISTANCE

Machined from a solid block of polypropylene, GP centrifugal pump casings are structurally and chemically very robust. Thanks to their thick-walled plastic body, not only are they highly resistant to corrosion, they are also not affected by dirty liquids or high temperatures.

PLASTIC IMPELLERS

Plastic impellers with no metal inserts: resistant to attack from acid, even on the inside. Wide internal gaps facilitate the passage of coarse solids and the pumping of charged liquids.

EXTREMELY ROBUST

GP plastic pumps are characterised by excellent hydraulic performance (flow rate and head). Their volute pump casing, machined from a solid block of material, guarantees excellent chemical and mechanical resistance. Moreover, their compact dimensions and flat impellers facilitate use in tanks that are shallow or have a reduced capacity, such as in wet fume control systems.

THE DETAILS THAT MAKE THE DIFFERENCE

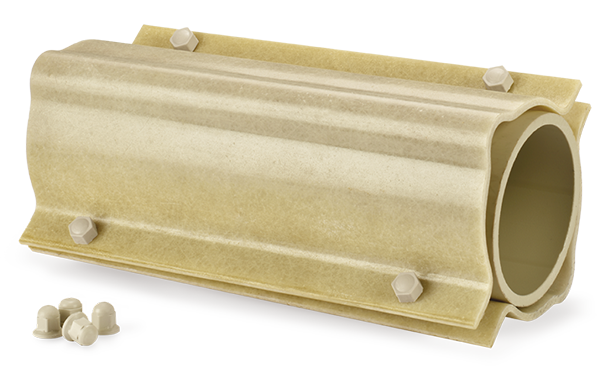

REINFORCEMENT IN FIBREGLASS

From lengths of 2000 mm upwards, Savino Barbera vertical pumps have aluminium motor supports, oversized shafts and fibreglass outer structures. This is a construction solution that ensures additional resistance to vibrations while protecting the pump from other mechanical or thermal stress.

WEAR BUSHINGS

GP pumps have no intermediate bearings, even in the longer versions (3000 mm). The only guide element consists of a pair of wear bushings positioned at the end of the pump shaft. The bushings are available in materials suited to chemical liquids, fluids containing sludge or suspended solids: filled-PTFE, sintered ceramic or silicon carbide.

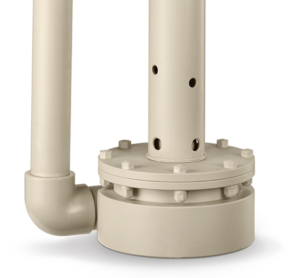

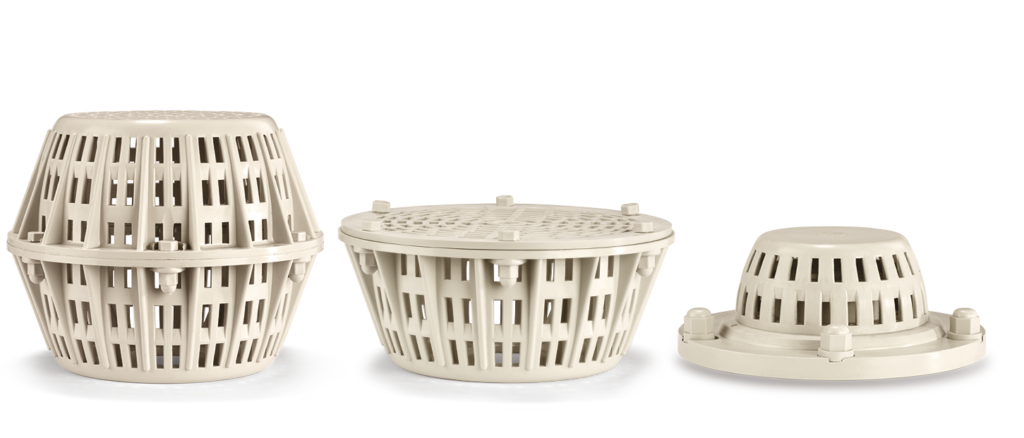

FILTERS AND EXTENSIONS

GP pumps can be fitted with suction extensions to reach extra lengths of 4 metres. They can also be equipped with filters to trap coarse impurities; the grill prevents the suction of residues or foreign bodies that are often found in industrial liquids. The filters are also available in a flat version to reduce the occupation of the bottom of the tank.

FOR DEMANDING OPERATIONS

The vertical pumps of the GP series are equipped with motors with oversized bearings (double row angular contact ball bearings) and PP fans resistant to acid vapours. These qualities make them particularly well-suited to heavy-duty services and continuous operations.

FOR DEMANDING OPERATIONS

The vertical pumps of the GP series are equipped with motors with oversized bearings (double row angular contact ball bearings) and PP fans resistant to acid vapours. These qualities make them particularly well-suited to heavy-duty services and continuous operations.

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

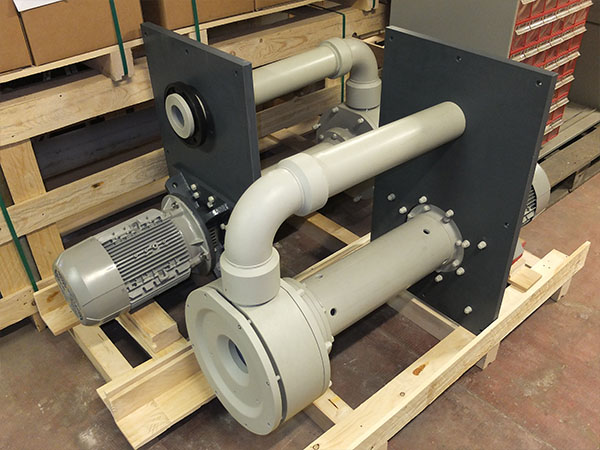

LATEST VERTICAL PUMPS SUPPLIES

CHEMICAL PUMP FOR A STEEL PLANT

GP80 vertical pump for a solution consisting of hydrogen peroxide, sulfuric acid, hydrofluoric acid and nitric acid.

GP80D PUMP FOR SULFURIC ACID

Vertical pump installed in a wire surface treatment line. Chemical liquid: washing water with sulfuric acid in traces.

FOR DEMINERALIZATION PLANT

Non metallic pump with 4000 mm shaft to handle water with hydrochloric acid and sodium hydroxide.

PUMPS WITH RUGGED DESIGN

Acid proof vertical pumps available in polyporopylene for scrubbing liquid in odour control systems.

FUME SCRUBBER PLASTIC PUMPS

Corrosion resistant chemical pumps for circulating acidic waters in an odour scrubbing installation.

HEAVY-DUTY CHEMICAL PUMPS

Plastic pumps with generously sized components for heavy duty operations in corrosive environments.