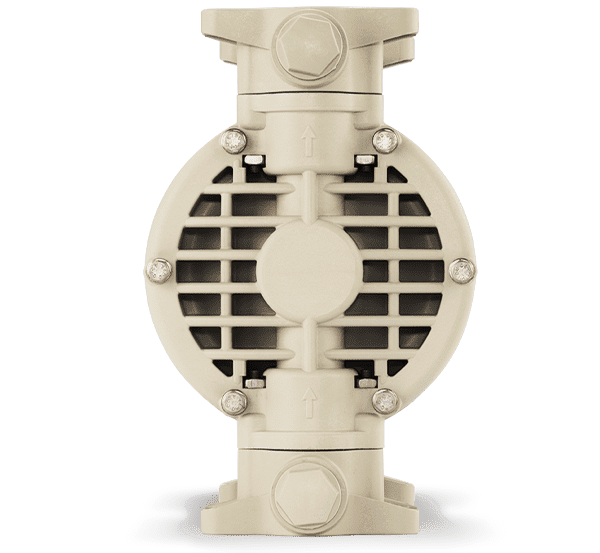

PNEUMATIC PUMPS FOR CORROSIVE LIQUIDS

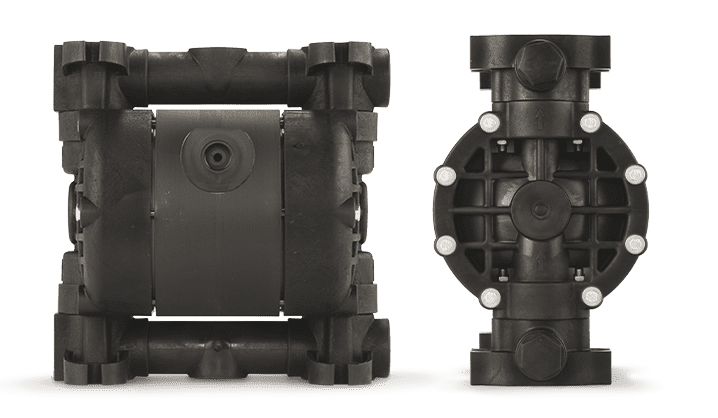

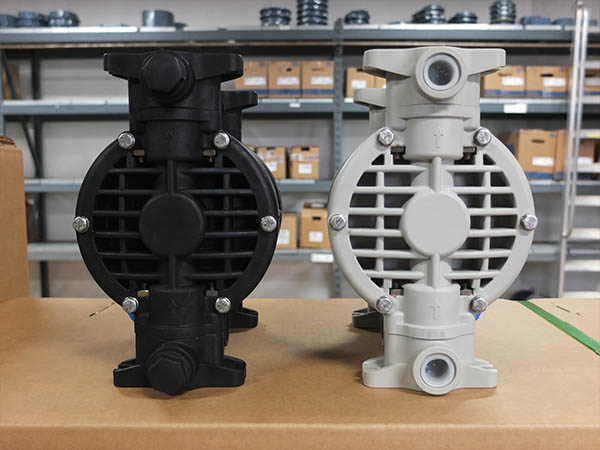

PLASTIC DOUBLE-DIAPHRAGM PUMPS

DOUBLE-DIAPHRAGM CHEMICAL PUMPS POWERED BY COMPRESSED AIR. IDEAL FOR: DENSE AND VISCOUS INDUSTRIAL LIQUIDS, ABRASIVE FLUIDS, AGGRESSIVE CHEMICALS, RESINS, PAINTS, ENAMELS, INKS, DYES, FUELS, OILS. MADE OF CORROSION-RESISTANT THERMOPLASTIC (PP, ECTFE, PVDF).

- Corrosion-resistant chemical pumps.

- Plastic construction materials: PP, PVDF, ECTFE.

- Maximum flow rate: 800 l/min.

- Maximum head: 80 m w.c.

- Maximum air pressure: 8 bar.

- Powered by non-lubricated compressed air.

- Suitable for dry running.

- ATEX Zone 2 certification: standard for all models.

TECHNICAL INFORMATION

| Q max l/min | Connections | Ø max solids | Max viscosity | Negative suction head | Link | ||||

|---|---|---|---|---|---|---|---|---|---|

| Liquid | Air | ||||||||

| BX5 | 6 | G1/4 f | G1/8 f | - | 800 cps | 3 m max |  |

||

| BX7 | 9 | G1/4 f | G1/8 f | 0.5 mm | 8.000 cps | 4 m max |  |

||

| BX13 | 16 | G3/8 f | G3/8 f | 0.5 mm | 10.000 cps | 3 m max |  |

||

| BX15 | 17 | G3/8 f | G3/8 f | 0.5 mm | 15.000 cps | 4 m max |  |

||

| BX30 | 35 | G1/2 f | G1/4 f | 2 mm | 20.000 cps | 4 m max |  |

||

| BX50 | 60 | G1/2 f | G3/8 f | 4 mm | 20.000 cps | 4 m max |  |

BX81 | 110 | G1 f | G3/8 f | 4 mm | 25.000 cps | 4 m max |  |

| BX100 | 160 | G1 f | G3/8 f | 4 mm | 30.000 cps | 4 m max |  |

||

| BX150 | 220 | G1 1/4 f | G1/2 f | 5 mm | 40.000 cps | 4 m max |  |

||

| BX251 | 340 | G1 1/2 f | G1/2 f | 6 mm | 50.000 cps | 4 m max |  |

||

| BX522 | 600 | G2 f | G1/2 f | 8 mm | 50.000 cps | 5 m max |  |

||

| BX503 | 800 | G3 f | G3/4 f | 10 mm | 50.000 cps | 4 m max |  |

||

BX series pumps are powered by a maximum air pressure of 8 bar. Performances refer to tests with cold, clean water with a density of 1000 kg/m3 (ISO9906) and to pumps with immersed suction and free delivery outlet.

download area

STRENGTHS

VOLUMETRIC PUMPS

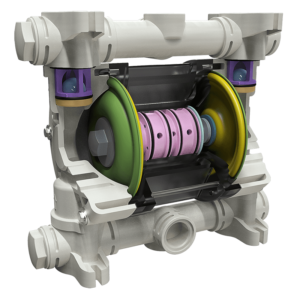

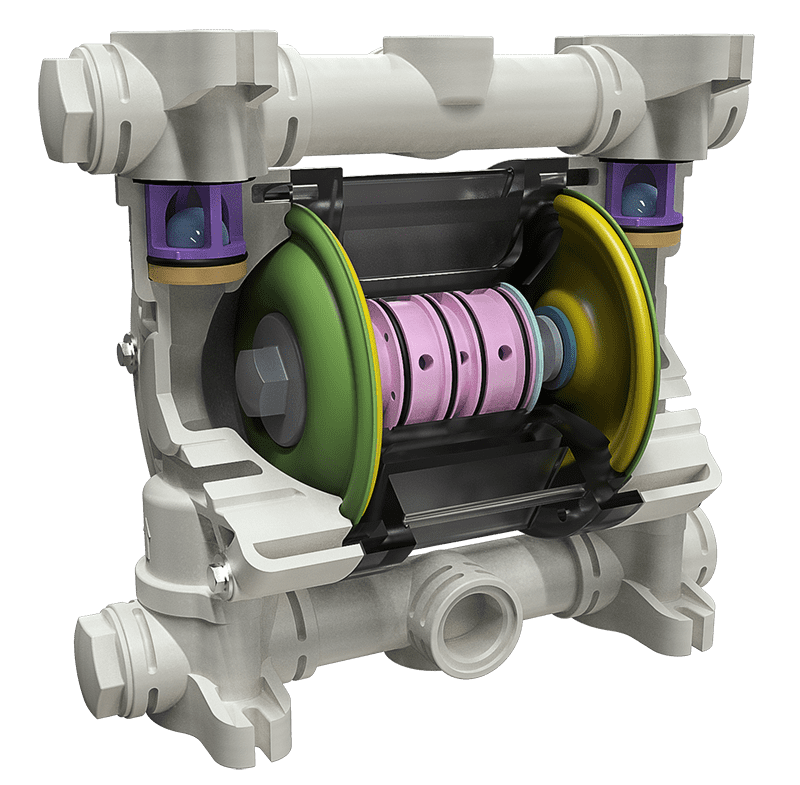

The BX AODD pump is a volumetric pump with pulsating flow rate. Two pairs of diaphragms inside them generate compression and depression: in this way the pump simultaneously creates vacuum (suction) and pressure (pumping).

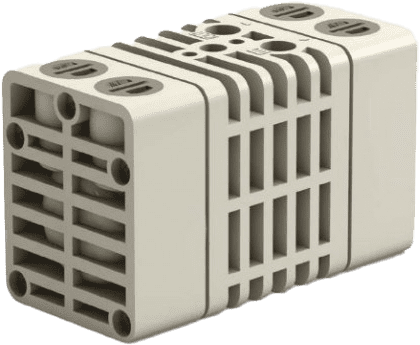

THE ACCESSORIES

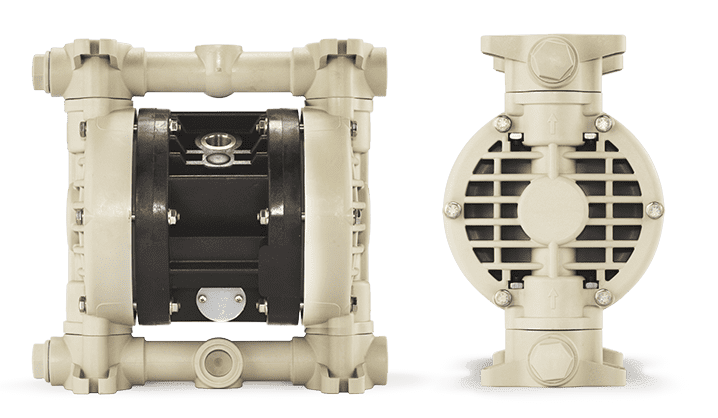

Three different delivery/suction positions. Possibility of split manifolds (two suctions and two deliveries). Optional features: automatic pulsation dampers, air adjustment kit, coupling flanges.

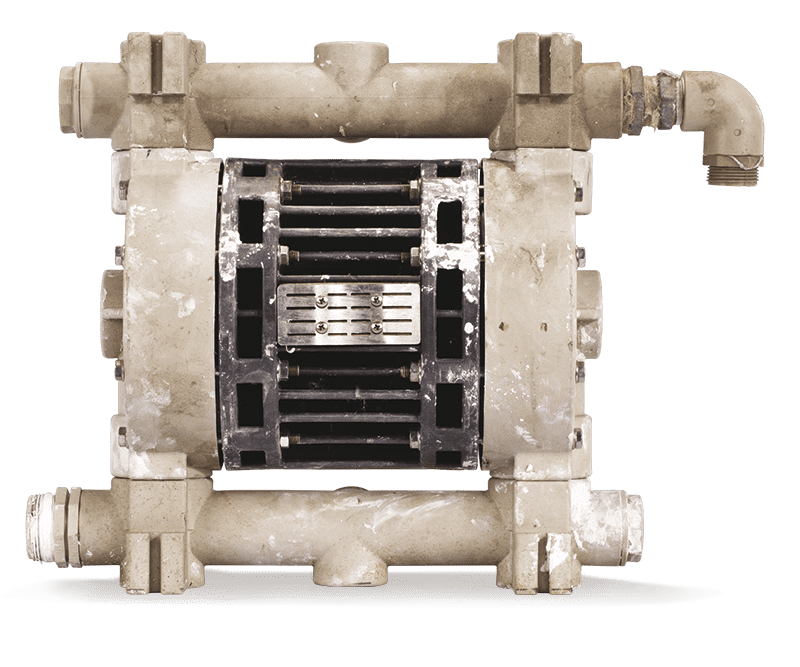

DIAPHRAGMS AND BALLS

Pump materials: anti-acid plastic (PP, PVDF, ECTFE). Diaphragm materials: plastic (HYTREL, SANTOPRENE), rubber (NBR, EPDM), PTFE. Ball materials: PTFE, AISI 316, EPDM, NBR.

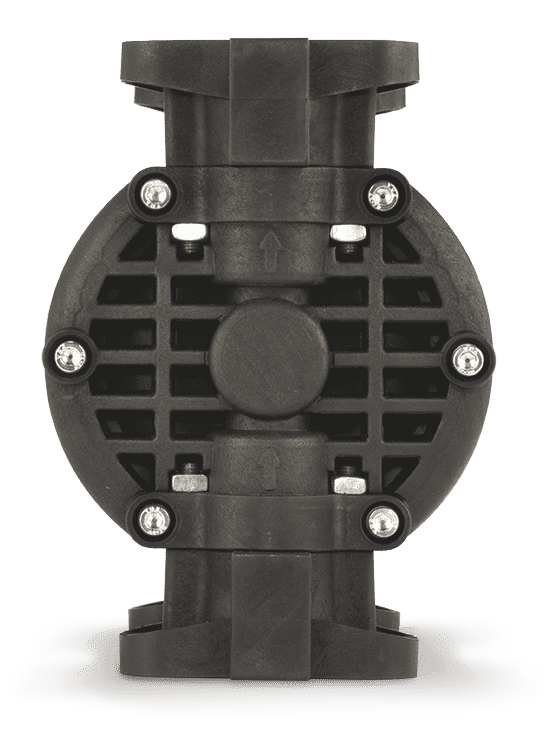

ATEX COMPLIANT

Standard material for all models: non-conductive thermoplastic (ATEX Zone 2 version). Special series by request: conductive plastic material filled with carbon fibre (ATEX Zone 1 version).

STRENGTHS

VOLUMETRIC PUMPS

The BX AODD pump is a volumetric pump with pulsating flow rate. Two pairs of diaphragms inside them generate compression and depression: in this way the pump simultaneously creates vacuum (suction) and pressure (pumping).

THE ACCESSORIES

Three different delivery/suction positions. Possibility of split manifolds (two suctions and two deliveries). Optional features: automatic pulsation dampers, air adjustment kit, coupling flanges.

DIAPHRAGMS AND BALLS

Pump materials: anti-acid plastic (PP, PVDF, ECTFE). Diaphragm materials: plastic (HYTREL, SANTOPRENE), rubber (NBR, EPDM), PTFE. Ball materials: PTFE, AISI 316, EPDM, NBR.

ATEX COMPLIANT

Standard material for all models: non-conductive thermoplastic (ATEX Zone 2 version). Special series by request: conductive plastic material filled with carbon fibre (ATEX Zone 1 version).

CHEMICALLY RESISTANT DIAPHRAGMS

There are two pairs of diaphragms inside the BX Air-Operated Double Diaphragm pumps (AODD pumps) and these are the elements subject to the greatest stress during suction and pumping (both at chemical and mechanical level). The diaphragms are designed to redistribute the load, minimising the yielding of the material. The possible anti-acid and wear-resistant configurations are: plastic (Hytrel, Santoprene), rubber (NBR, EPDM) or PTFE.

THERMOPLASTIC MATERIALS

PP (POLYPROPYLENE)

The most widely used thermoplastic polymer for the construction of corrosion-resistant pneumatic pumps. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, at temperatures of approximately 65-70°C max.

PVC (POLYVINYL CHLORIDE)

Fluorinated thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but is ideal for highly concentrated acids. It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

TYPICAL APPLICATIONS

- Chemical and petrochemical systems

- Pumping solvents, oils, lubricants

- Handling fuels

- Emptying cisterns and tanks

- Treatment of dense or abrasive fluids

- Assembly in painting lines

- Transferring solutions for printed circuit boards

- Use on service platforms

- Pumping slurries, pastes, resins

- Seawater treatment

- Electroplating baths, pickling, galvanisation

- Feeding rotary machines

- Handling inks

- Loading and unloading chemicals

TYPICAL APPLICATIONS

- Chemical and petrochemical systems

- Pumping solvents, oils, lubricants

- Handling fuels

- Emptying cisterns and tanks

- Treatment of dense or abrasive fluids

- Assembly in painting lines

- Transferring solutions for printed circuit boards

- Use on service platforms

- Pumping slurries, pastes, resins

- Seawater treatment

- Electroplating baths, pickling, galvanisation

- Feeding rotary machines

- Handling inks

- Loading and unloading chemicals

AODD PUMPS: OTHER FEATURES

BX membrane pumps are perfect for some extreme applications involving the handling and dosing of industrial liquids and corrosive chemicals. They are designed to work even with high viscosities and suspended solids. Moreover, use in very humid or explosive environments, the self-priming capability from high suction heights, the possibility to fine tune the speed and for dry pumping means that these pumps have unprecedented levels of versatility. Their pneumatic motor is self-lubricating: it must be fed by oil-free, filtered, dried, non-lubricated air. The pressure of the air supply must be between 2 and 8 bar. Unfortunately, a certain amount of noise and a pulsating flow rate are almost unavoidable characteristics: but when there is no alternative, these AODD pumps do their job very well.

KEY CORROSIVE LIQUIDS

- Nitric acid

- Muriatic acid

- Citric acid

- Brine

- Ammonia

- Caustic potash

- Chemical fertilisers

- Fertilisers

- Glycerine, glycol

- Fuels and biodiesel

- Solvents of various kinds

- Seawater

- Sulphuric acid

- Caustic soda

- Hydrochloric acid

- Sodium hydroxide

- Chromic acid

- Sodium hypochlorite

- Hydrofluoric acid

- Ferric chloride

- Aluminium polychloride

- Phosphoric acid

- Acetic acid

- Flocculants, polyelectrolytes

- Urea and AdBlue

- Sanitising gels

- Inks, dyes, paints

- Vegetable and industrial oils

- Cosmetic liquids

- Industrial detergents

- Distilled water

- Demineralised water

- Hydrogen peroxide

- And your liquid, of course!

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST DIAPHRAMG PUMPS SUPPLIES

SPACE-SAVING DESIGN

Air-operated diaphragm pumps feature a compact design perfect fot industrial environments with space limitations.

ACIDIC DEGREASING SOLUTIONS

Anti-acid AODD pumps in thermoplastic material (PP) for acidic degreasing wastes (water with oil at 50%).

VISOCOUS AND ABRASIVE LIQUIDS

Savino Barbera AOOD pumps are manufactured for handling corrosive solid-laden, viscous and abrasive fluids.

SAFE CHEMICAL HANDLING

Corrosion resistant air-powered double diaphragm pump made from PVDF for chemically aggressive liquids.

PUMPING HYDROCHLORIC ACID

Chemical AODD pump for hydrcochloric acid. Materials: PVDF (pump) and PTFE/Santoprene (membranes).

NO METAL IN CONTACT WITH FLUIDS

Pneumatic double diaphragm pumps in PP for water-based paint (right) and PVDF for chlorine (left).

ZINC PLATING TREATMENTS

Non-metallic diaphragm pumps for zinc based bath (plating process with zinc chloride and ammonium).

PUMPS FOR NAOH AND NACLO

AODD pump for caustic soda (big pump in PP) and AODD pump sodium hypochlorite (small pump in PVDF).

POLYPROPYLENE AODD PUMPS

Air-operated double diaphragm pumps constructed with polypropylene body for complete corrosion resistance.

PUMP FOR SODIUM HYPOCHLORITE

Double diaphragm pump with PVDF construction and pneumatic motor for 15% sodium hypochlorite.

PUMPS FOR AIR SCRUBBING SYSTEMS

Air-powered double diaphragm pumps for circulating a corrosive solution of HCl in a wet scrubbing tower.

ACETIC ACID AND FORMIC ACID

AODD pump for acetic acid and EDTA (right) and AODD pump for formic acid and hydrogen peroxide (left).

PUMPS FOR MARINE APPLICATIONS

Air-operated chemical double diaphragm pump for sea water mixed with oils and hydrocarbons.

CHEMICAL MANUFACTURING PUMPS

Corrosion resistant plastic AOOD pump for transferring highly aggressive sulfuric acid in a chemical plant.

EMPTYING TANKER TRUCKS

Chemical resistant pumps for loading and unloading tank trucks. Bulk liquids: sodium hydroxide and sodium chloride.

FURTHER CORROSION RESISTANT PUMPS