MAGNETICALLY DRIVEN CHEMICAL PUMPS

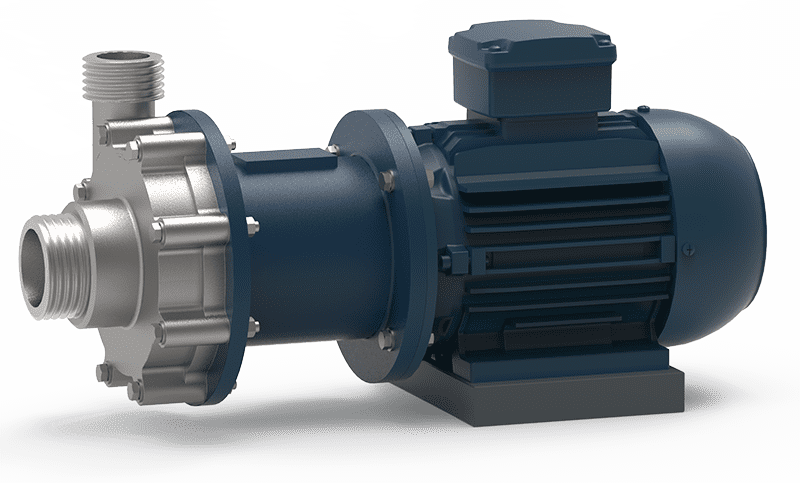

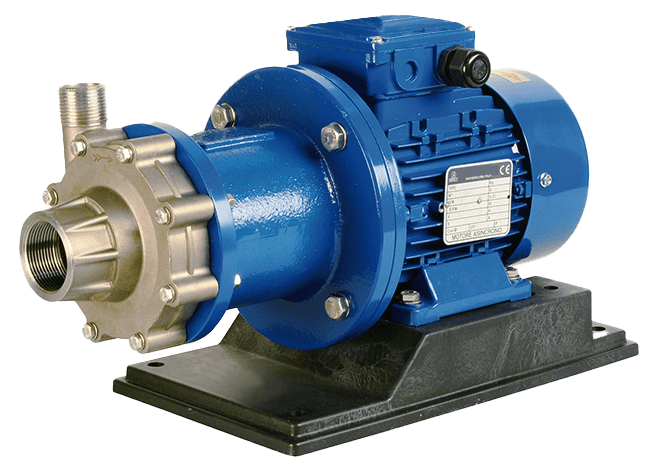

METAL MAG-DRIVE PUMPS

METAL MAGNETICALLY COUPLED CHEMICAL PUMPS. HERMETIC DESIGN WITH NO MECHANICAL SEAL. LEAK-PROOF MAG DRIVE PUMPS IDEAL FOR TOXIC AND HAZARDOUS LIQUIDS. PRINCIPLE INDUSTRIES SERVED INCLUDE CHEMICAL, PETROCHEMICAL, PHARMACEUTICAL AND ELECTROPLATING APPLICATIONS.

- Corrosion-resistant chemical pumps.

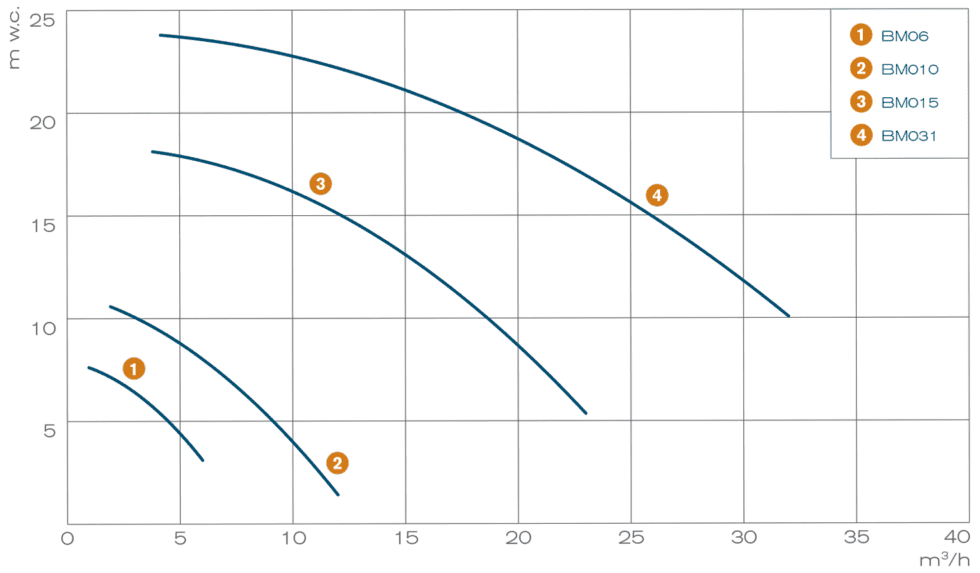

- Maximum flow rate: 32 m³/h.

- Maximum head: 24 m w.c.

- Construction material: AISI 316.

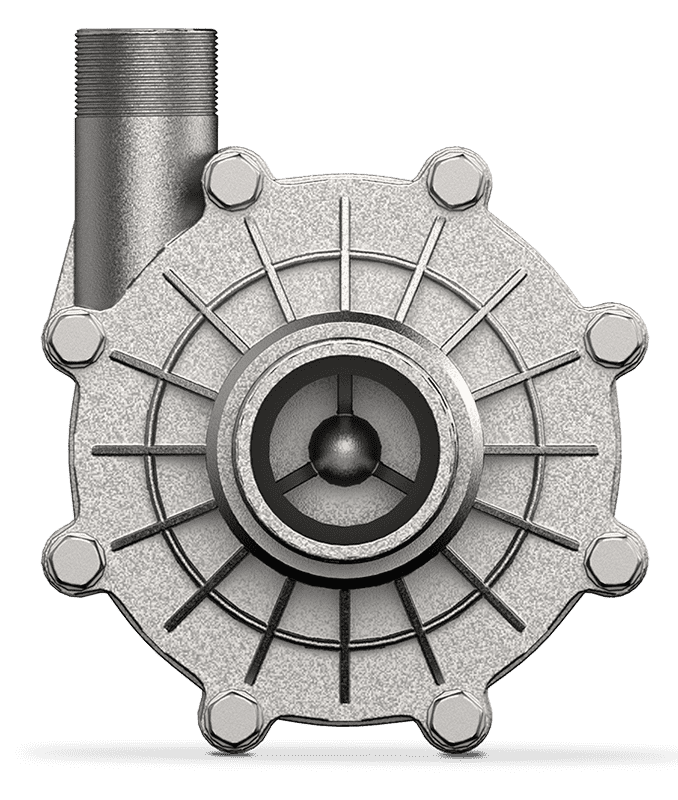

- Threaded pumps (standard version) or with flange (by request).

- Samarium Cobalt (SmCo) permanent magnets.

- Opposing magnets encapsulated in corrosion-resistant plastic.

- Also for explosive environments (specific models by request).

- Only for clean liquids with no solids (especially if metallic).

TECHNICAL INFORMATION

Standard curves: 50 Hz (60 Hz curves available on request). Maximum rated pressure: PN6 @ 20°C. The curves refer to tests with cold, clean water and a density of 1000 kg/m3 (ISO9906). Hydraulic performance may change in relation to changes in the characteristics of the liquid to be pumped.

Special non-standard motors can also be mounted: in this case, we recommend that you contact our technical department.

download area

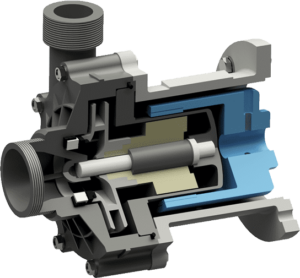

MAGNETIC DRIVE COUPLING

SEALLESS PUMPS

The absence of dynamic seals and magnetic coupling between pump and motor, at least virtually, prevent external leakage. Their maintenance, however, is usually more expensive than with pumps with mechanical seals.

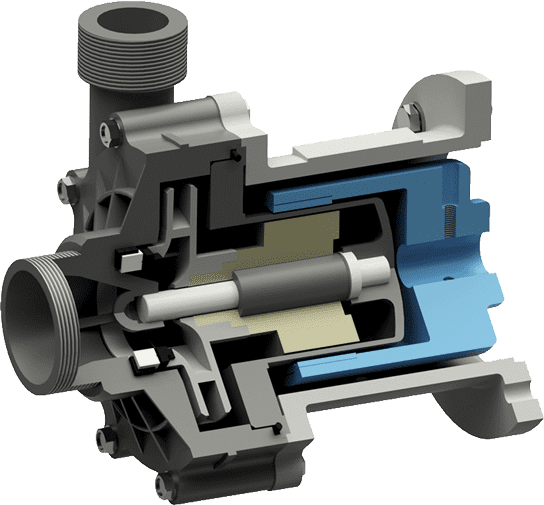

CONTACT-FREE

The external magnet, coupled to the motor shaft, conveys movement to the internal magnet which is attached to the impeller. As the motor shaft does not extend inside the pump body, the contact-free magnetic pump is incapsulated and protected from corrosion.

CLEAN LIQUIDS ALWAYS

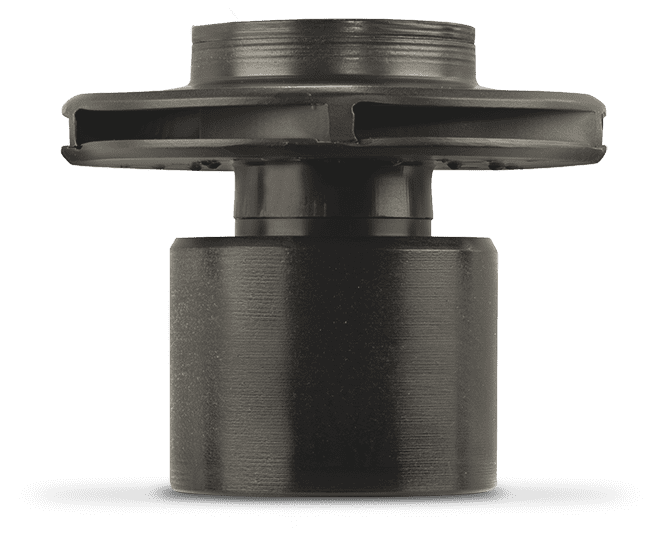

The thin plastic coating of the magnets and the closed channels of the impellers do not withstand liquids with abrasive solids and suspended particles, especially when metallic. Over-saturated liquids could also pose a problem for magnetic pumps.

METAL MAG-DRIVE PUMPS

In metal magnetic pumps, the body and impeller are made of AISI 316 (standard version). Bushings: Charged PTFE or graphite. O-ring: EPDM or FPM. Shaft: Hastelloy C-276. Construction materials by request: Hastelloy and Titanium.

SEALLESS PUMPS

The absence of dynamic seals and magnetic coupling between pump and motor, at least virtually, prevent external leakage. Their maintenance, however, is usually more expensive than with pumps with mechanical seals.

METAL MAG-DRIVE PUMPS

In metal magnetic pumps, the body and impeller are made of AISI 316 (standard version). Bushings: Charged PTFE or graphite. O-ring: EPDM or FPM. Shaft: Hastelloy C-276. Construction materials by request: Hastelloy and Titanium.

CLEAN LIQUIDS ALWAYS

The thin plastic coating of the magnets and the closed channels of the impellers do not withstand liquids with abrasive solids and suspended particles, especially when metallic. Over-saturated liquids could also pose a problem for magnetic pumps.

CONTACT-FREE

The external magnet, coupled to the motor shaft, conveys movement to the internal magnet which is attached to the impeller. As the motor shaft does not extend inside the pump body, the contact-free magnetic pump is incapsulated and protected from corrosion.

SEALED PUMPS VS MAGNETIC PUMPS

Magnetic pumps are considered to be hermetically sealed pumps. Their presumed tightness must be scrupulously evaluated in relation to the characteristics of the liquid being pumped. The choice of mag-drive pumps can be influenced by incorrect installation habits rather than by real technical needs. Magnetically coupled pumps are often preferred to mechanically sealed pumps in the belief that the former are safer, but their use requires particular attention to specific working conditions.

ATEX CERTIFICATION

AND OTHER OPTIONS

BM magnetic drive chemical pumps are also available in versions for ATEX Zone 1 and ATEX Zone 2, for use in potentially explosive environments. Magnetic drive seal-less pumps with these characteristics can be used in areas classified as being at risk of explosion. In addition to ATEX certification, BM magnetic drive pumps (both plastic and metal) can also be equipped with other optional features such as: explosion-proof motors (Ex-d), 60 Hz motors, flanges, PP baseplates.

KEY CHEMICALS

- Glycol

- Acetone

- Butyl acetate

- Ethyl acetate

- Benzene, ethanol

- Ethyl alcohol

- Isobutanol

- Solvents

- Pyrophosphates

- Coolants

- Ammonia

- Industrial oils

- Flammable liquids

- Caustic soda

- Ferric chloride

- Hydrocarbides

- Paints

- Acetic acid

- Glycerine

- Diathermic oil

- And your liquid, of course!

KEY CHEMICALS

- Glycol

- Acetone

- Butyl acetate

- Ethyl acetate

- Benzene, ethanol

- Ethyl alcohol

- Isobutanol

- Solvents

- Pyrophosphates

- Coolants

- Ammonia

- Industrial oils

- Flammable liquids

- Caustic soda

- Ferric chloride

- Hydrocarbides

- Paints

- Acetic acid

- Glycerine

- Diathermic oil

- And your liquid, of course!

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST MAG-DRIVE PUMPS SUPPLIES

ATEX RATED MAG-DRIVE PUMP

Metallic magnetic drive pump for a mixture of alcohol (99%) and silicones (1%). Pump certified for Atex Zone 1.

FOR HAZARDOUS LIQUIDS

Horizontal magnetically driven pumps made of stainless steel to be used with hazardous fluids (flammable liquids).

PUMPS FOR SOLVENTS (ISODECANE)

Centrifugal sealless magnetic drive pumps in AISI316 for pumping solvents with explosion-proof motor.

MAGNETIC PUMP FOR OIL

Hermetically sealed industrial pump manufactured in for diathermic oil at temperature of 60°C with Atex Approval.

FURTHER CORROSION RESISTANT PUMPS