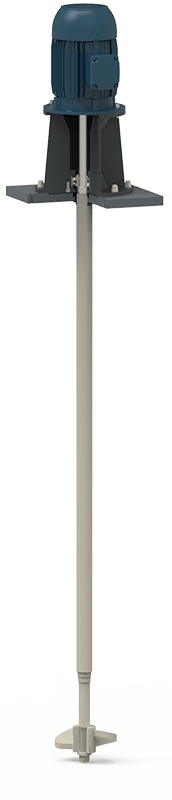

TOP-ENTRY MIXERS FOR DEMANDING OPERATIONS

AL HEAVY-DUTY MIXERS

FLANGE MOUNTED TOP-ENTRY MIXERS FOR TANKS AT ATMOSPHERIC PRESSURE. WITH LANTERNS AND OVERSIZED BEARINGS FOR ADDITIONAL SHAFT STABILITY. CUSTOM-MADE LENGTHS TO SUIT THE DEPTH OF THE TANK.

- Corrosion-resistant industrial mixers.

- High-speed mixers (with no gear reducer).

- With bearing support for heavy-duty applications.

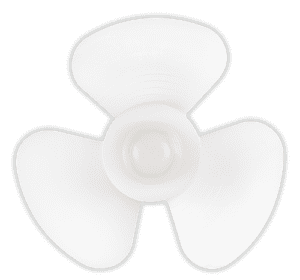

- Reversible 3-blade marine propellers.

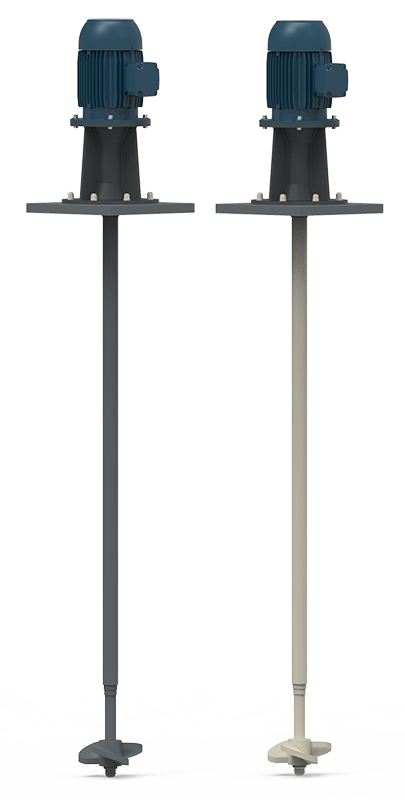

- Mixer materials: PP, PVC, PVDF.

- Impeller materials: PP, PVC, PVDF.

- 4-6-8-pole electric motors.

- Can be used with an inverter (60 Hz max).

- Coupled to the motor with a lantern and joint.

- Custom-made lengths between 500 and 1900 mm.