INDUSTRIAL MIXERS

CORROSION-RESISTANT TOP-ENTRY MIXERS

Vertical mixers with direct drive or coupled to gearmotors. Made of corrosion-resistant plastic (PP, PVC, PVDF) and metal (AISI 304). Suitable for traditional industrial mixing requirements and countless chemical applications. Their extremely versatile modular design allows their use for even less common types of mixing. Available in seven main production lines, they offer rotation speeds from 50 to 2800 rpm depending on the service required (gentle mixing, moderate mixing, vigorous mixing).

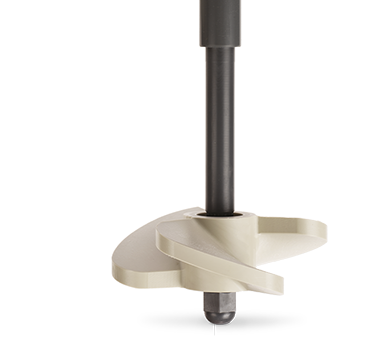

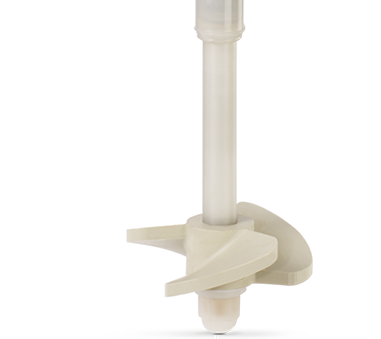

AN MIXERS: HIGH SPEED MIXERS

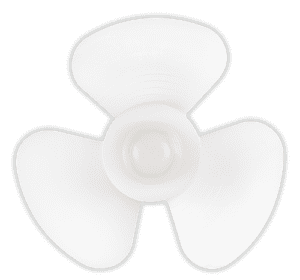

Mixers with cantilevered bare shaft connected directly to the motor. They are particularly suitable for liquid-solid mixing and treating liquids with solids in suspension. Maximum length: 1300 mm. Fast rotation. Impeller with marine propeller.

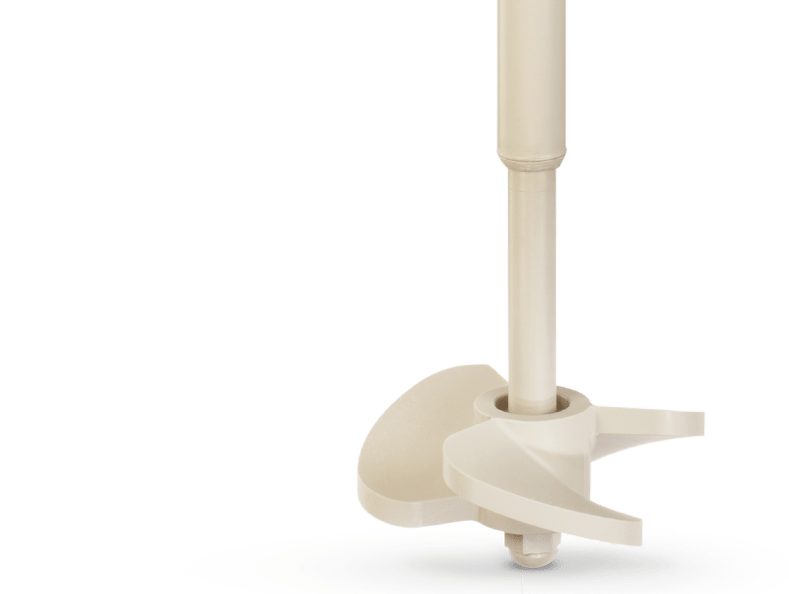

AR MIXERS: SLOW ROTATION

Mixers with cantilevered shaft connected to the gearmotor with a coupling. With no guide bushings, they are fitted with a three-blade impeller ideal for gently mixing liquids. Maximum length: 3500 mm. Slow rotation. High-performance impeller.

AG MIXERS: SUPPORTED SHAFT

Mixers with guided shaft. Maximum length: 3000 mm. The mixer shaft is inserted inside a column and is supported by a coulple of bushing near the end. Fast rotation. Impeller with marine propeller.

AL MIXERS: FOR HEAVY-DUTY USE

Mixers with cantilevered shaft and oversized bearings for heavy duty use. The coupling to the motor consists of an aluminium lantern and joint. Maximum length: 1750 mm. Fast rotation. Impeller with marine propeller.

AP MIXERS: INTUBATED PROPELLER

Pumping mixers (or axial pumps) with a propeller inside a pipe. For decentralised placement in the tank. Maximum length: 2000 mm. AP mixers ensure powerful movement of the liquid and a continuous and homogeneous circulation of the liquids mixed.

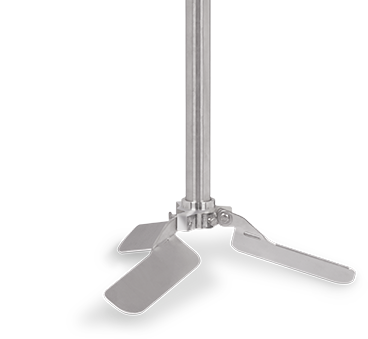

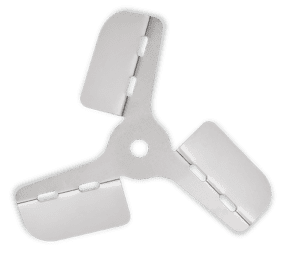

AF MIXERS: FOLDING IMPELLERS

Small mixers with folding blade impellers. With the possibility of fitting multiple impellers (up to 3). Ideal for IBCs. Maximum length: 2000 mm. Construction material: stainless steel (AISI304). Slow rotation.

STANDARD MIXERS FOR IBC

Mixers (AN30 and AF50) with cantilever shaft suitable for containers with small openings. Fast rotation and direct coupling (AN30) or slow rotation with gearmotor (AF50). Impellers with marine propeller, axial turbines with inclined blades, or folding blade impellers.

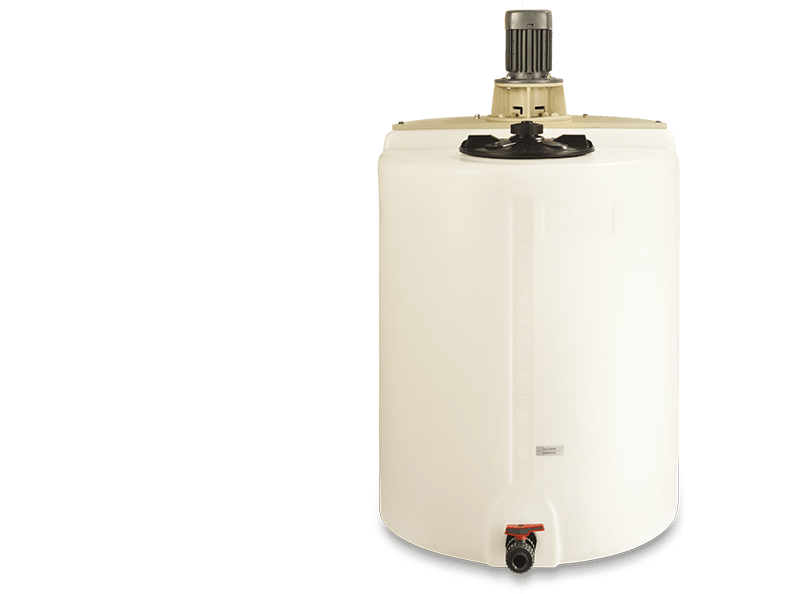

MIXING UNITS

Mixing units consisting of AN or AR corrosion-resistant mixers and tanks of various capacities. Maximum length: 1350 mm. Maximum volume: 1040 litres. Accessories available: metallic frames, valves, containment tanks.

MIXERS TO SUIT EVERY NEED

Savino Barbera also make special non-standard mixers. If you have special mixing needs, we are always willing to find the solution that is right for you.

AN MIXERS: HIGH SPEED MIXERS

Mixers with cantilevered bare shaft connected directly to the motor. They are particularly suitable for liquid-solid mixing and treating liquids with solids in suspension. Maximum length: 1300 mm. Fast rotation. Impeller with marine propeller.

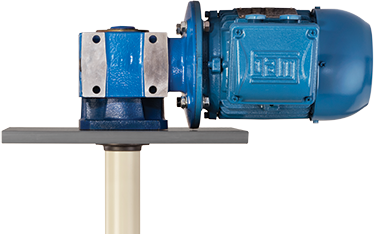

AR MIXERS: SLOW ROTATION

Mixers with cantilevered shaft connected to the gearmotor with a coupling. With no guide bushings, they are fitted with a three-blade impeller ideal for gently mixing liquids. Maximum length: 3500 mm. Slow rotation. High-performance impeller.

AG MIXERS: SUPPORTED SHAFT

Mixers with guided shaft. Maximum length: 3000 mm. The mixer shaft is inserted inside a column and is supported by a coulple of bushing near the end. Fast rotation. Impeller with marine propeller.

AL MIXERS: FOR HEAVY-DUTY USE

Mixers with cantilevered shaft and oversized bearings for heavy duty use. The coupling to the motor consists of an aluminium lantern and joint. Maximum length: 1750 mm. Fast rotation. Impeller with marine propeller.

AP MIXERS: INTUBATED PROPELLER

Pumping mixers (or axial pumps) with a propeller inside a pipe. For decentralised placement in the tank. Maximum length: 2000 mm. AP mixers ensure powerful movement of the liquid and a continuous and homogeneous circulation of the liquids mixed.

AF MIXERS: FOLDING IMPELLERS

Small mixers with folding blade impellers. With the possibility of fitting multiple impellers (up to 3). Ideal for IBCs. Maximum length: 2000 mm. Construction material: stainless steel (AISI304). Slow rotation.

STANDARD MIXERS FOR IBC

Mixers (AN30 and AF50) with cantilever shaft suitable for containers with small openings. Fast rotation and direct coupling (AN30) or slow rotation with gearmotor (AF50). Impellers with marine propeller, axial turbines with inclined blades, or folding blade impellers.

MIXING UNITS

Mixing units consisting of AN or AR corrosion-resistant mixers and tanks of various capacities. Maximum length: 1350 mm. Maximum volume: 1040 litres. Accessories available: metallic frames, valves, containment tanks.

MIXERS TO SUIT EVERY NEED

Savino Barbera also make special non-standard mixers. If you have special mixing needs, we are always willing to find the solution that is right for you.

MIXERS TO SUIT EVERY NEED

You would never guess how much you can achieve with a motor, a plastic-coated metal shaft and an impeller. Our mixers can be fitted with propellers with the most varied geometries. They can have cantilever shafts, guided shafts or shafts with draft tube. They can be very short or very long. They can be coupled to tanks, becoming practical mixing units. They can be installed in horizontal tanks with a low level of liquid or in very deep vertical tanks. They can be supplemented by extra support for heavy-duty operations. In short, our industrial mixers can be many things!

TECHNICAL CHARACTERISTICS

DIRECT DRIVE MIXERS

Fixed mixers with flange for vertical installation in atmospheric pressure tanks. Available in seven main lines but easily customised for particular operating conditions.

CORROSION-RESISTANT PLASTIC

No metal parts in contact with liquid. The shafts are plastic-coated and the impellers are made entirely of technical polymers (PP, PVC, PVDF).

WHAT TYPE OF MIXING?

Liquid-liquid and liquid-solid mixing. Keeping particulate in suspension. Reaching particular temperatures. Homogenisation of acid solutions. Recirculation to eliminate stratification.

FAST, MEDIUM, SLOW

Industrial mixers with 4, 6 and 8-pole motors. They can be fitted with gear reducers (usually angular gearmotors and sometimes coaxial gearmotors). For vigorous, moderate or gentle rotation.

CUSTOM-MADE LENGTHS

Custom-made vertical mixers with maximum lengths of 3500 mm. With cantilever shafts or guide bushings: the shafts are in one piece with no intermediate supports.

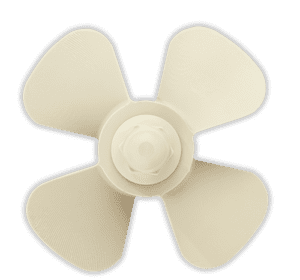

PLASTIC IMPELLERS

Available in varying geometries: three-blade marine propellers, radial or axial turbines, high efficiency, retractable impellers. They have no internal metal inserts, making mixing safe and vibration-free.

TECHNICAL CHARACTERISTICS

DIRECT DRIVE MIXERS

Fixed mixers with flange for vertical installation in atmospheric pressure tanks. Available in seven main lines but easily customised for particular operating conditions.

CORROSION-RESISTANT PLASTIC

No metal parts in contact with liquid. The shafts are plastic-coated and the impellers are made entirely of technical polymers (PP, PVC, PVDF).

WHAT TYPE OF MIXING?

Liquid-liquid and liquid-solid mixing. Keeping particulate in suspension. Reaching particular temperatures. Homogenisation of acid solutions. Recirculation to eliminate stratification.

FAST, MEDIUM, SLOW

Industrial mixers with 4, 6 and 8-pole motors. They can be fitted with gear reducers (usually angular gearmotors and sometimes coaxial gearmotors). For vigorous, moderate or gentle rotation.

CUSTOM-MADE LENGTHS

Custom-made vertical mixers with maximum lengths of 3500 mm. With cantilever shafts or guide bushings: the shafts are in one piece with no intermediate supports.

PLASTIC IMPELLERS

Available in varying geometries: three-blade marine propellers, radial or axial turbines, high efficiency, retractable impellers. They have no internal metal inserts, making mixing safe and vibration-free.

THERMOPLASTIC MATERIALS

PP

The most widely used

anti-acid plastic polymer for use in corrosive environments. It offers good resistance to most acid and alkaline solutions and can be used, depending on the concentration of the aggressive liquids, up to a temperature of 80°C.

PVC

Plastic material with excellent resistance to acids, bases, saline solutions and organic compounds. PVC is generally used when treating sodium hypochlorite (NaClO).

At low temperatures it becomes fragile. The operating temperature is between 40 and 60°C.

PVDF

Thermoplastic with exceptional resistance to corrosion and temperature. PVDF covers a wide range of uses but

is ideal for highly concentrated acids.It is not suitable for certain inorganic bases, such as caustic soda. Operating temperature: max. 100°C

AISI 304

Savino Barbera mixers are also available in stainless steel. This version can be used to mix industrial liquids that are not particularly aggressive, such as: fertilisers, manures, quenching treatments, wastewater, graphite suspensions. Operating temperature: max. 100°C

WIDE RANGE OF ACCESSORIES

- Special flanges made to customer design and installation of vapour seals (V-ring).

- Additional safety: double containment tanks.

- Transportable version: equipped with metal frame on wheels.

- Fixed version: fixed metal lifting structure.

- IBC supports: metal structures with holes for lifting forks.

- Mixers designed for use with inverter.

- Mixing stations: equipped with mixing tanks.

- Fitting of coaxial gearmotors (instead of angular gearmotors).