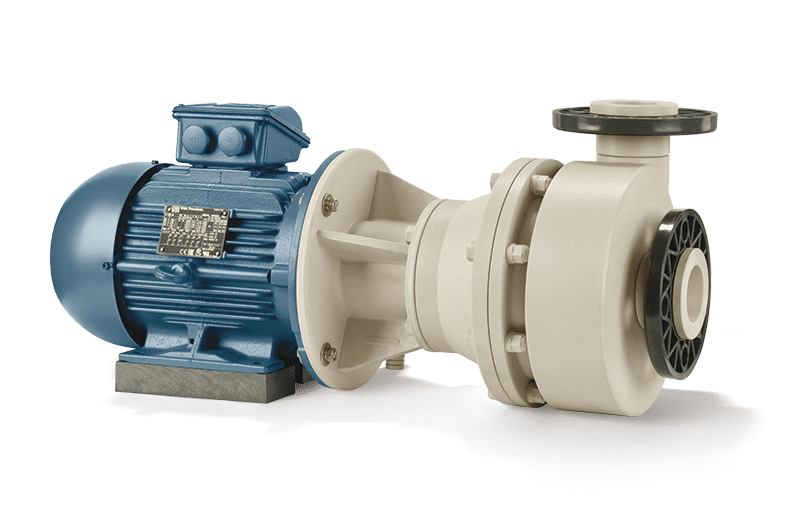

CHEMICAL PUMPS FOR CORROSIVE LIQUIDS

OA HORIZONTAL PUMPS

CORROSION-RESISTANT PLASTIC PUMPS. WITH MECHANICAL SEAL AND NON-CLOGGING IMPELLERS, IDEAL FOR PUMPING AGGRESSIVE LIQUIDS OR EVEN VERY DIRTY INDUSTRIAL FLUIDS (COARSE SOLIDS, FIBRES, FILAMENTS, ETC.).

- Corrosion-resistant chemical pumps.

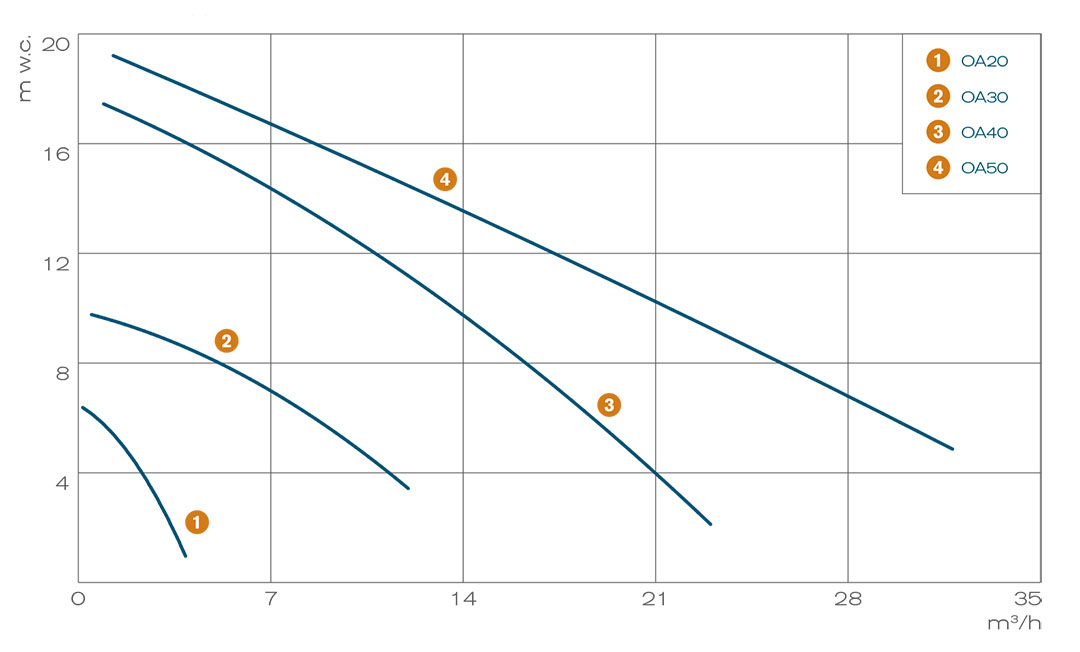

- Maximum flow rate: 32 m³/h.

- Maximum head: 20 m w.c.

- Plastic construction materials: PP, PVC, PVDF.

- Mechanically sealed for chemical applications.

- With no metal parts in contact with aggressive liquids.

- Lots of internal space and recessed non-clogging impeller.

TECHNICAL INFORMATION

Savino Barbera also manufactures custom pumps outside this production range: the table does not indicate all the possible combinations of impellers and motors. It is possible to install various types of impeller and motors with non-standard powers, voltages, frequencies and protections. Please contact our technical department for any special requirements.

download area

STRENGTHS

LESS METAL, LESS CORROSION

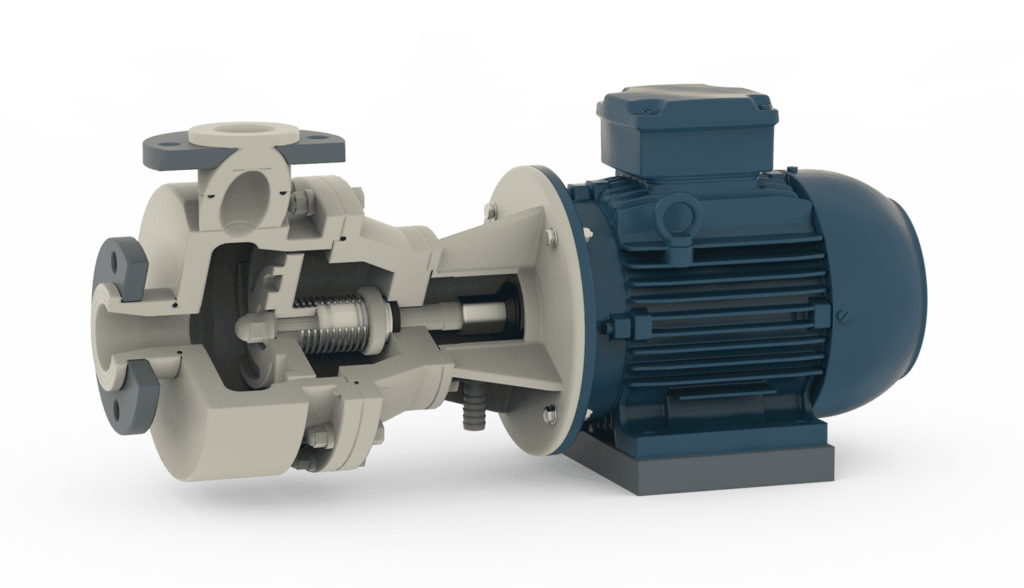

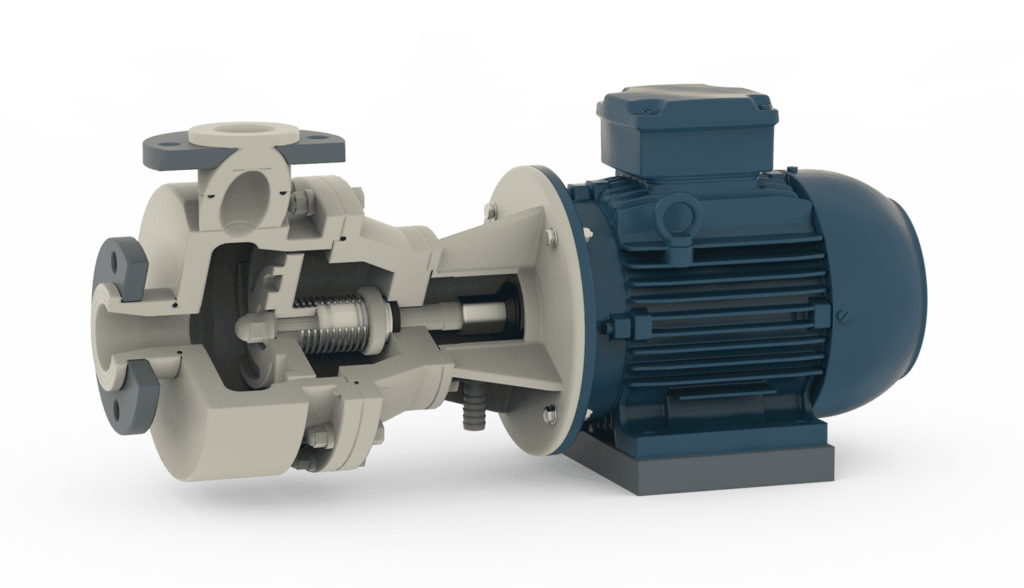

MECHANICAL SEAL

The anti-acid performance of our chemical pumps also comprises the mechanical seal, which is completely insensitive to corrosion. Consisting of just three elements, it requires no adjustment or regulation with screws.

DRY-RUNNING

In the version with double mechanical seal, OA chemical pumps have the ability to run dry without problems, eliminating a classic limit of all plastic pumps.

SOLIDS AND FILAMENTS

Thanks to their internal gap and flat impeller, OA pumps can pump very dirty liquids. They are horizontal pumps with a recessed impeller suitable for aggressive liquids containing coarse solids, filaments or other impurities typically found in certain industrial fluids.

STRENGTHS

LESS METAL, LESS CORROSION

OA horizontal pumps are made of corrosion-resistant plastic material (PP, PVC, PVDF). All wetted parts are insensitive to corrosion and are built with maintenance in mind, using simplified components which can be easily removed over time.

MECHANICAL SEAL

The anti-acid performance of our chemical pumps also comprises the mechanical seal, which is completely insensitive to corrosion. Consisting of just three elements, it requires no adjustment or regulation with screws.

DRY-RUNNING

In the version with double mechanical seal, OA chemical pumps have the ability to run dry without problems, eliminating a classic limit of all plastic pumps.

SOLIDS AND FILAMENTS

Thanks to their internal gap and flat impeller, OA pumps can pump very dirty liquids. They are horizontal pumps with a recessed impeller suitable for aggressive liquids containing coarse solids, filaments or other impurities typically found in certain industrial fluids.

DRY RUNNING!

The recessed non-clogging impeller and spaces inside the pump-casing make the OA a perfect chemical pump for extreme use, such as the handling of liquids containing suspended solids (conventional mechanical seal arrangement) or when there is a risk of running dry (special double mechanical seal arrangement). In this last case, OA plastic pumps can also be used when the liquid no longer reaches the pump for some reason.

OPTIONS THAT MAKE A DIFFERENCE

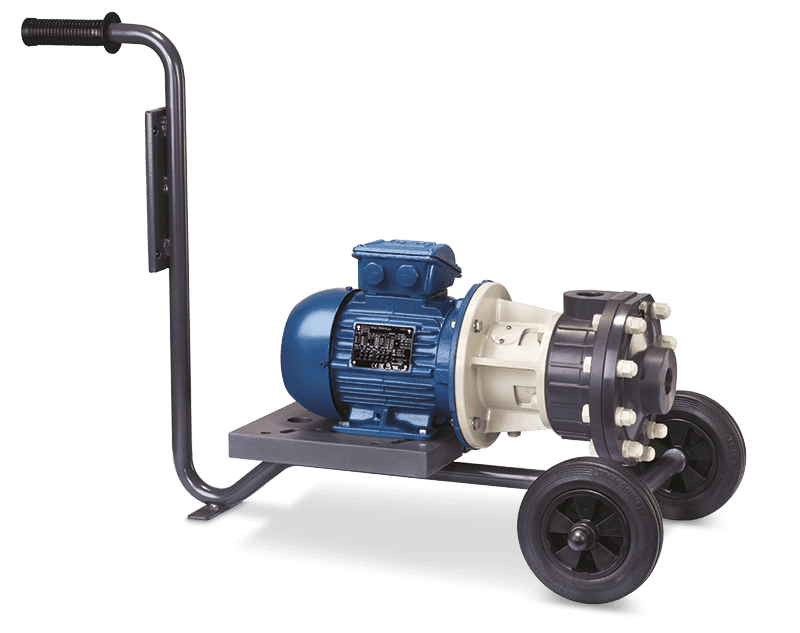

TROLLEY-MOUNTED PUMPS

The close-coupled construction of Savino Barbera’s horizontal centrifugal pumps makes them easy to mount on wheels. Transformed into practical portable units, the trolley-mounted pumps can reach the most awkward corners of your systems for use in quick operations, occasional jobs and emergency operations (like filling and emptying tankers or emptying tanks in places far away from pipes or other fixed installations). The transport trolley is a powder- painted steel structure with a handle and with rubber and polypropylene wheels, to ensure silent movement and prevent damage to the floor.

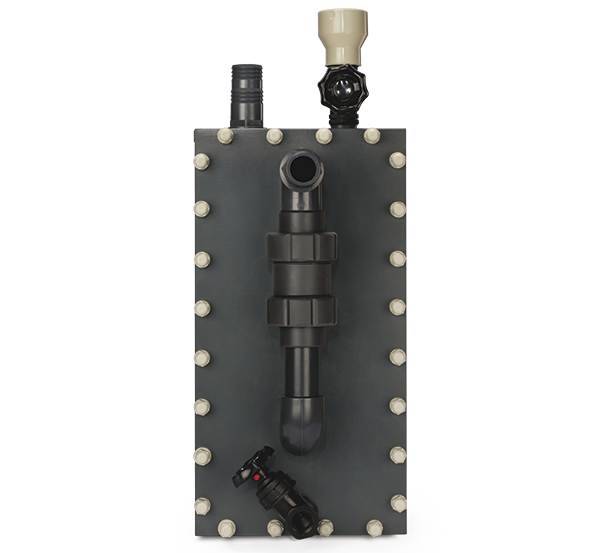

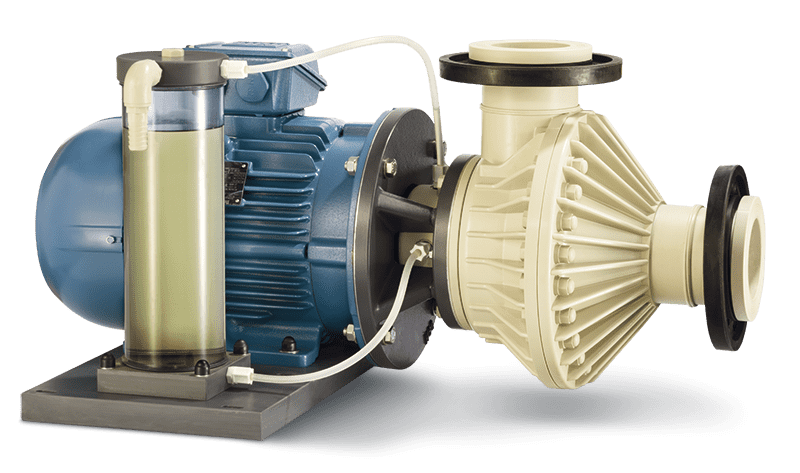

DOUBLE MECHANICAL SEAL

OA pumps are also available with double mechanical seal flushed by liquids: with this execution, the traditional features of the conventional single seal (product side) are joined by the advantages of a secondary seal (atmosphere side). The double seal allows the plastic pump to work in critical conditions and even when there is no liquid (dry running). This solution prevents the seal faces from sticking and facilitates the pumping of liquids at very low temperatures, with crystals, oxides or solid deposits. Consequently, it represents an additional safety mechanism against dry starting or the formation of scale.

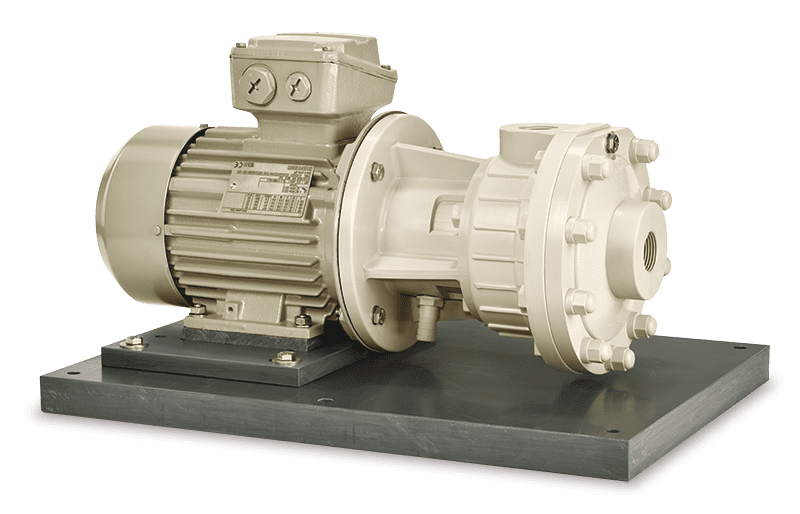

BASEPLATES

Baseplates for assembly with pumps equipped with B3/B5 motors. They allow perfect horizontal alignment with the system. OA chemical pumps can be anchored to various types of baseplates: single support feet made of PVC or stainless steel to secure the motor only, or large PVC baseplates to support the entire pumping unit. The plastic baseplates are extra thick (PVC sheets with a maximum thickness of 70 mm, for larger pumps), with standard dimensions and pre-drilled holes. However, they can also be custom-made if special sizes and shapes are required.

CHEMICAL APPLICATIONS

- Chemical and petrochemical systems

- Electroplating baths

- Pickling lines, galvanisation

- Metal wire treatment

- Fume and odour control

- Scrubbers and washing towers

- Seawater treatment

- Demineralisation plants

- Acid water neutralisation

- Purification plants

- Recovery of precious metals

- Production of batteries

- Regeneration units

- Production of fertilisers

- Industrial logistics of fluids

- Wastewater pumping

DO YOU HAVE A REQUEST ?

TALK TO OUR EXPERTS

SUBMIT YOUR ENQUIRY

LATEST horizontal PUMPS SUPPLIES

PUMP FOR FILAMENTARY SOLIDS

Acid-proof pump for water with traces of sulphuric acid and caustic soda containing solids and stringy materials.

LIQUIDS WITH SOLIDS AND FIBRES

OA horizontal chemical pumps are not affected by dirty liquids thanks to their large free passage clearance.

SOLIDS HANDLING ABILITY

The flat recessed impeller allows particles and sludge to pass throught the pump preventing blockages and clogs.

FURTHER PLASTIC HORIZONTAL PUMPS